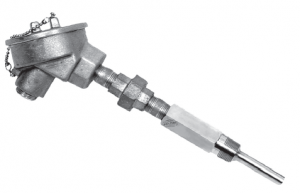

Thermowell is a cylindrical shape installed like a cantilever into the process piping. It facilitates temperature measurement while resisting process fluid forces. Thermowells are pressure tight receptacles adapted to receive a temperature sensing element. It is also provided with external threads or other means for tight pressure attachment to a vessel or pipe. Thermowells are used in measuring the temperature of a moving fluid in a conduit, where the stream exerts an appreciable force. Thermowells are generally fabricated by bore drilling bar stock.

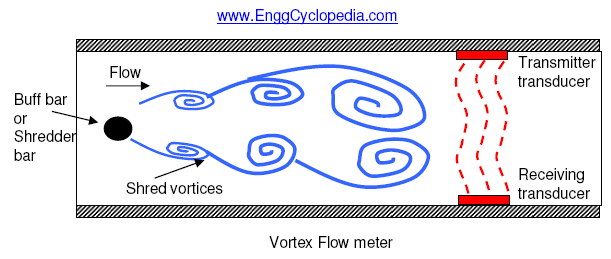

Its Design requires thermal & stress consideration; its ability to withstand static pressure, steady-state fluid impingement, turbulence, & dynamic excitation due to Von Karman vortices.

Usage of thermowells

- Protect temperature sensing elements installed in a tank, vessel or pipe from breaking

- Facilitate servicing by easy removal of temperature sensing elements without plant shutdown

- Use as Test wells.

- Protection tubes are used in high temperature flue gas service and duct applications.

Thermowell Materials

- Thermowell material should match pipe and fitting material to avoid dissimilar welds unless process requires other material of construction.

- Refer to a Material selection guide offered by ASME B31.3 & 31.1 or by the vendor. Check for Pressure-Temperature rating for that particular material from the P-T tables.

- Recommendation of the process licensor or material specialist should be followed for special application.

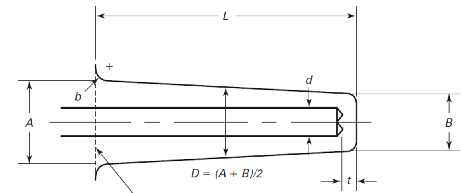

Thermowell Terminology

L= Unsupported Length

B= Tip Diameter

(B-d)/2= Minimum Wall Thickness

A=Root Diameter

d= Bore Diameter

B/A= Taper Ratio

L/B= Aspect Ratio

d/B= Bore Ratio

- Immersion Length (R): The distance between the free end/tip of the thermowell and the point of immersion in the medium, this is being measured.

- Insertion Length (U): The distance between the free end/tip of a thermowell and (but not including) the external threads of other means of attachment to a vessel.

- Bore Dia. (d): Diameter of inner bore in which the temperature element is installed.

- Lagging Extension (T): Pipe insulation or lagging extension is the extra length provided between the thermowell piping connection and the temperature element connection. This extension also acts as a heat sink, which may cause an error in the measurement.

Notes:

- U is always equal to or larger than R.

- Immersion in pipe such that sensitive area in center third of line but no less than 2”.

- Immersion in vessel shall be of min. 6” depth inside vessel wall.