Butterfly valves have been in use since the invention of steam engines. A butterfly valve is a type of quarter-turn valve that is commonly used in various industries to control the flow of fluids through pipes or ducts. This comprehensive guide aims to shed light on butterfly valves, providing insights into their parts, working principle, applications, advantages, and disadvantages.

Table of content:

1. What is a butterfly valve?

2. How does a butterfly valve work?

3. Parts of butterfly valve

4. Types of butterfly valve

5. Advantages

6. Disadvantages

7. Applications of butterfly valves

What is a butterfly valve?

Butterfly valves have been in use since the invention of steam engines. The initial butterfly valves were available in large sizes (6" and above) and were used mainly for low pressure drop applications.

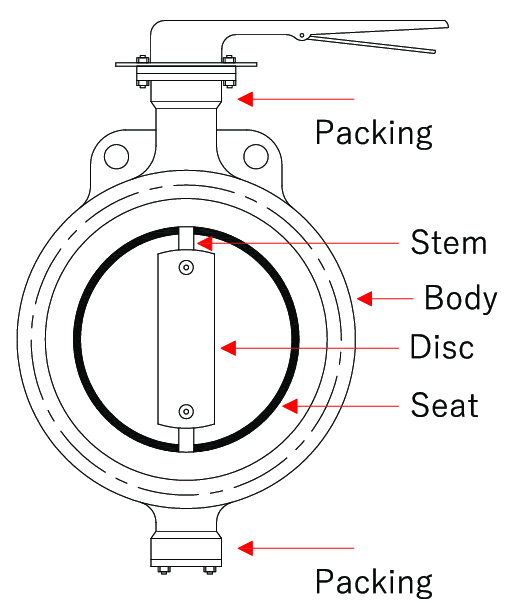

As can be seen in the figure, a butterfly valve essentially consists of a disc which blocks the flow. This disc can be rotated about an axis passing through the plane of the disc. Rotation of the disc by 90 degrees can completely open or close the butterfly valve. Use of a smooth disc as the closure member allows the valve to be operated with low torque.

Butterfly valves are named after the shape of their disc, which resembles the wings of a butterfly. The disc is typically mounted on a shaft that runs through the center and extends beyond the valve body. The shaft is connected to an actuator, which can be manually operated, pneumatically controlled, or driven by an electric motor. The actuator rotates the disc to control the flow.

The structure of a butterfly valve does not produce as much disturbance in the flow compared to other valves due to its simplicity. Due to their unique structure, these valves are smaller than all other valves. Moreover, they have high flow capacities compared to other valves. Hence, the use of butterfly valves can result in reduced weight, space, and overall cost requirements.

Butterfly valves have only a couple of parts in contact with the process fluid. A variety of linings can be used to isolate the valve body from process fluids thus avoiding the requirement of expensive materials for the valve body. This also contributes to cost reduction due to the use of butterfly valves over other valves.

How does a butterfly valve work?

One of the defining characteristics of a butterfly valve is its quarter-turn operation. This means that the disc rotates a quarter of a full circle (90 degrees) to control the flow. The disc can be positioned parallel to the flow, allowing for unrestricted fluid passage when the valve is fully open. Conversely, rotating the disc to a perpendicular position blocks the flow, closing the valve.

The disc's position directly influences the flow of fluid through the valve. When the disc is fully open, the fluid encounters minimal obstruction, resulting in low pressure drop across the valve. By adjusting the disc's angle, the flow can be throttled or completely shut off, providing precise control over the fluid flow rate.

The valve can operate in three main positions: fully open, fully closed, and throttling.

Fully Open Position: In the fully open position, the disc is rotated parallel to the flow direction. This allows the fluid to pass through the valve with minimal obstruction. This configuration provides maximum flow capacity and minimum pressure drop.

Fully Closed Position: When the butterfly valve is fully closed, the disc is rotated perpendicular to the flow direction. This effectively blocks the passage of fluid. In this position, the valve provides a tight seal and prevents fluid passage through it.

Throttling Position: Butterfly valves can also be positioned to throttle or control the flow rate of fluid. By adjusting the angle of the disc, the valve allows for partial flow control. The disc is positioned at an intermediate angle between fully open and fully closed, creating a variable restriction in the flow path.

Parts of butterfly valve

A butterfly valve consists of several key parts that work together to control the flow of fluids. The main parts of a butterfly valve are discussed here.

Body: The body of the butterfly valve is the main casing that houses the internal components. It provides the connection points for the pipeline and supports the other parts of the valve.

Disc: The disc, also known as the butterfly, is a circular or semicircular plate that is connected to the valve stem. It rotates within the body to control the flow of fluids. When the disc is turned parallel to the flow direction, it allows for maximum flow, and when it is turned perpendicular, it blocks the flow.

Stem: The stem is a shaft that connects the disc to the actuator or handle. It transmits the motion from the actuator to the disc, allowing it to rotate and control the flow. The stem is usually located off-center and passes through the center of the disc in concentric butterfly valves.

Seat: The seat is the sealing surface that the disc presses against to create a tight shut-off when the valve is closed. It is typically made of resilient material such as rubber or PTFE (polytetrafluoroethylene). The seat ensures a proper seal and prevents leakage when the valve is closed.

Actuator: The actuator is the mechanism that controls the movement of the disc. It can be manual, such as a lever or handwheel, or automated, such as pneumatic, electric, or hydraulic actuators. The actuator applies force to the stem, causing the disc to rotate and adjust the flow.

Packing: Stem packing is a sealing material that surrounds the stem and prevents leakage along the stem. It provides a barrier between the stem and the valve body, ensuring a tight seal even under high-pressure conditions.

Types of butterfly valve

The butterfly valves can be classified on the basis of disc closure design and end piping connection. Types of butterfly valves on the basis of disc closure design are as given below.

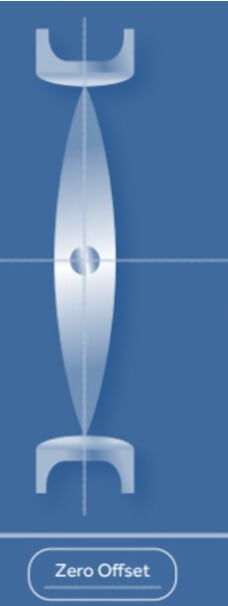

1. Concentric butterfly valve (Zero offset)

This is the most common type of butterfly valve. Zero offset butterfly valves have a flat disc that seals against the seat in the valve body. The stem and disc of a zero offset valve are situated in the center. When the valve is closed, the disc makes full contact with the seat, creating a tight seal. The disc is designed to seal against a seat in the valve body to control flow. This design is suitable for applications that require a bubble-tight shut-off.

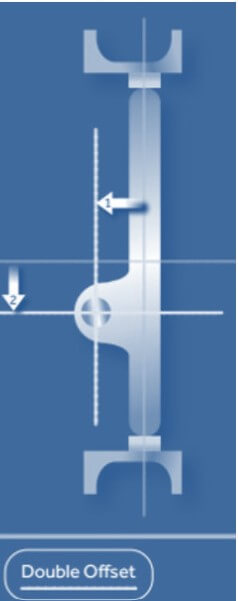

2. Double offset butterfly valve

A double-offset butterfly valve is a type of butterfly valve that has two offset features. The first offset is the center of the stem is offset from the center of the disc. The second offset is the center of the valve body is offset from the center of the disc. Double offset in butterfly valves means the disc is both offset and tilted.

The double offset design reduces wear on the disc and seat by allowing the disc to leave the seat quickly and smoothly. This is because the disc does not have to scrape against the seat as it rotates. The reduced wear on the disc and seat leads to a longer operational life for the valve.

The double offset design allows the use of metal seats in butterfly valves. Metal seats are more resistant to corrosion and erosion than soft seats, making them ideal for high-temperature applications.

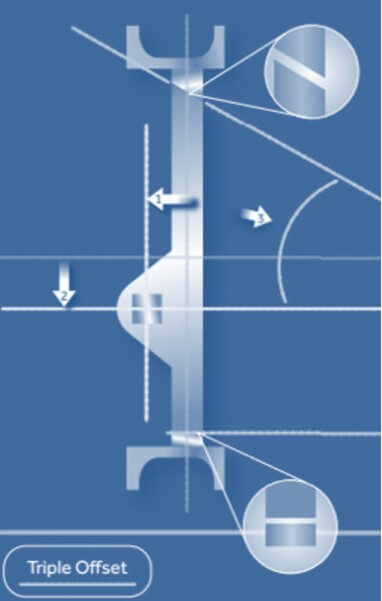

3. Triple offset butterfly valve

Triple offset butterfly valves have a unique design that eliminates rubbing between the seat and seal ring. The term "triple offset" refers to the three offsets in the valve design. In addition to the eccentric disc position (offset from the centerline of the valve body), a triple offset butterfly valve also has two additional offsets: the shaft axis is offset from the centerline of the disc, and the cone axis is offset from the centerline of the valve body.

This design reduces wear and tear on the valve, extending its lifespan. Triple offset butterfly valves can also be opened and closed more quickly than traditional butterfly valves. Additionally, triple offset butterfly valves have low torque.

(Image courtesy: legacy.garlock.com)

Butterfly valves can also be classified based on their piping connection method. The two common types based on piping connection are described here.

1. Wafer Butterfly Valve

Wafer butterfly valves are designed to fit between two flanges in a pipeline. They have a wafer-like profile with holes for bolts that pass through the flanges and the valve body, securing the valve in place. Wafer butterfly valves are lightweight, compact, and relatively cost-effective. They are suitable for applications where space is limited and where quick and easy installation is required. However, they do not provide a means for line isolation.

2. Lug Butterfly Valve

Lug butterfly valves have threaded lugs on either side of the valve body. These lugs allow the valve to be bolted into the pipeline using separate bolts without requiring complete removal of the flange bolts. Lug butterfly valves provide a secure connection and allow for easy installation and removal without disrupting the entire pipeline. They are commonly used in applications where regular maintenance or removal of the valve is necessary.

Advantages

- As mentioned above, use of these valves can result in reduced costs thanks to the small size, small weight, lesser space requirements, lesser requirement of expensive materials etc.

- They have few parts, even fewer exposed to the fluids, making them easy to maintain.

- They can be easily and quickly operated by turning the disc by 90 degrees.

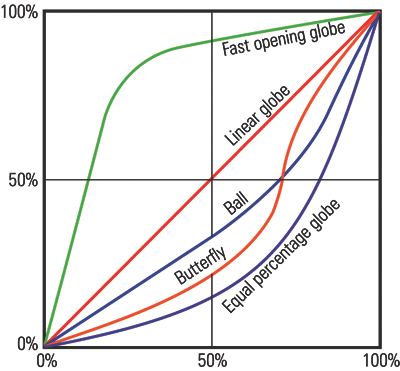

- They are suitable for control purpose and can offer good rangeability.

- These valves are easily available in larger sizes.

Disadvantages

- The use of these control valves for control applications is limited to the valve opening range between 30 degrees to 70 degrees.

- Throttling using butterfly valves is limited to low pressure drop applications.

- Potential cavitation is a concern when butterfly valves are used.

- Also, possibility of a choked flow is a concern.

Applications of butterfly valves

- Throttling service requiring low pressure drop.

- Corrosive service needing lining in the valves.

- Slurry or abrasive service.

- High pressure and high temperature water or steam service.

- Cooling water, fire water, circulating water etc.

- Vacuum service