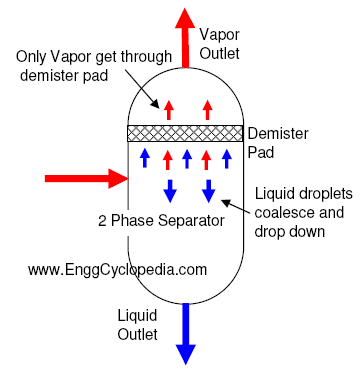

A 'spiral flow type' cyclone gas liquid separator is a filtering device used for separating solid particles or liquid droplets from gas flow. These devices are typically used in two phase separators at the gas outlet, to enhance the overall separation efficiency of the equipment. The structure of spiral flow internal devices do not need the gas to change the main flow direction, unlike in the conventional type cyclone separators. Instead, the flow is simply rotated about an axis along the flow direction or in other words the flow is spiraled along its flow direction. This spiraling motion is responsible for slowing down entrained solid particles or liquid droplets, which eventually get condensed and drained out.

Since there is no major change in the gas flow direction, the pressure drop across spiral flow type cyclone gas liquid separator is very low compared to conventional cyclone separators. Hence they can be used as separator internals to enhance gas liquid separation efficiency.

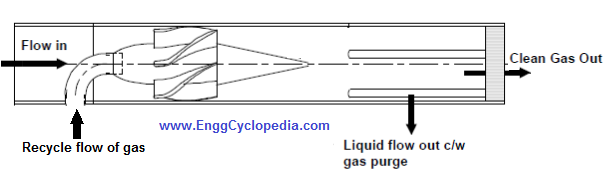

Figure 1 - Schematic of a spiral flow internal filter device

Figure 1 - Schematic of a spiral flow internal filter device

Operation of spiral flow type filters

The principle of operation of spiral flow type internals is based on the separation of the liquid and dust particles by centrifugal forces. Initially the gas enters the spiral flow type internal through a cylindrical inlet, which leads to spiral shaped vanes as indicated in figure-1. These spiral vanes are responsible for imparting a radial velocity to the gas flow. Due to this radial component of gas velocity, entrained liquid and solid particles get thrown to the tube wall and settle down, thus separated from gas flow. Eventually the liquid accumulated in the spiral flow internal device get drained through tubes which lead to a pool of separated liquid in the gas liquid separator vessel. Some of the gas flow also goes to the liquid carrying tubes and is recycled back to the spiral flow tube to minimize gas losses.

Application of spiral flow type separator internals

The main difference between conventional cyclone separator and cyclone gas liquid separator internals is the extent of radial velocity of gas. In cyclone separators, almost the entire gas flow is radilly directed when it enters the separator. This causes a big momentum change for gas, resulting in a significant pressure loss. For cyclone type internals, the radial component of gas velocity is smaller compared to overall velocity. The change is gas momentum is small, hence smaller pressure loss across the cyclone shaped vanes. Hence when the pressure drop across the gas liquid separators is of critical importance, two phase separators equipped with cyclone type liquid removal internals can be used for high gas liquid separation efficiency. Cyclone type internals can also be used for retrofitting purposes, where separation efficiency of an existing gas liquid separator is needed to be improved.