Demineralizers or ion exchangers are equipments which can hold ion exchange resins. Different type of demineralizers are used for water purification.

Role of Demineralizers

Dissolved impurities and foreign particles entrained in power plant fluid systems generate corrosion problems and decrease the heat exchanger efficiency as a result of fouling of relevant heat exchanger surfaces. Demineralization of water is one of the most commonly used processes to remove dissolved impurities.

Demineralizers or Ion exchangers

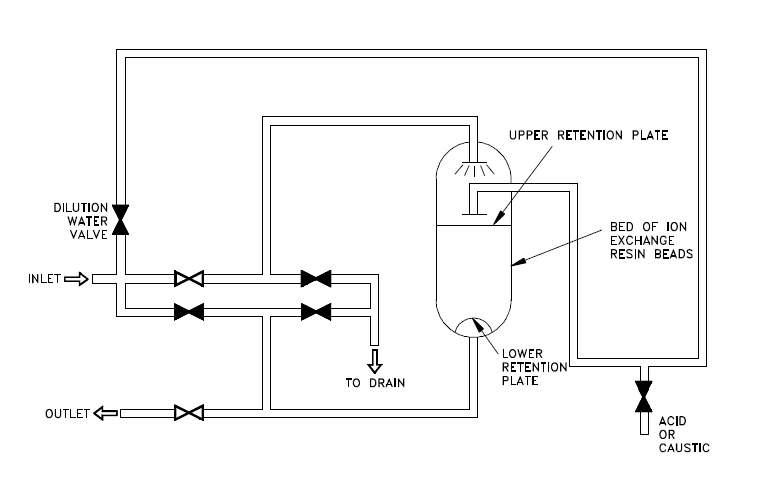

Demineralizers or ion exchangers are equipments which can hold ion exchange resins. Demineralization or ion exchange refers to exchange of ions between a solid substance (called a resin) and an aqueous solution (makeup water). Ion exchange resins consist of very small beads, termed resin beads, having an average diameter of 0.010 millimeters or less. After a certain period of time, ion exchange resins are exhausted and they have to be regenerated. During regeneration, an acid solution (for cation exchange units) and a caustic solution (for anion exchange units) is used, properly diluted with water, which is typically distributed above the resins. Regeneration is usually a multi-step process, also involving backwashing and rinsing stages in order to remove any entrained particles.

Types of demineralizers or ion exchangers

Ion exchangers are generally classified into two groups: single-bed ion exchangers and mixed-bed ion exchangers.

The most common design parameter or demineralizers is conductivity. Typical conductivity value for the demineralized water at the outlet of mixed bed demineralizers is less than 0.1 μS/cm. Other typical design parameters of demineralizers also include demineralizer water in silica, copper, iron and sodium.

Layout of demineralizers or ion exchangers

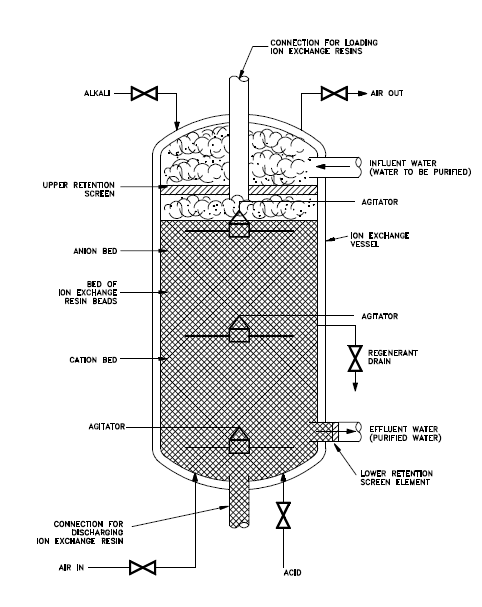

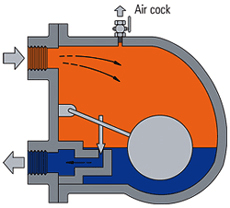

A demineralizer is basically a cylindrical tank with connections at the top for water inlet and resin addition, and connections at the bottom for the water outlet. The resin elements are stored in the demineralizer by upper and lower retention elements, which are strainers with a mesh size smaller then the ion exchange resin elements. The water to be purified enters the top at a specific flow rate and flows down through the resin elements, where the flow is filtered and a chemical ion exchange also takes place. Deionized water is taken out from bottom outlet.

Single bed demineralizers

A single bed demineralizer contains either cation resin elements (a cation is an ion with a positive charge: common cations include Ca++, Mg++, Fe++, and H+) or anion resin elements (an anion is an ion with a negative charge: common anions include Cl-, SO-, and OH-). Consequently, a cation resin is one that exchanges positive ions, whereas an anion resin is one that exchanges negative ions.

In most cases, there are two, single bed ion exchangers installed in series; the first one being a cation bed and the second one an anion bed.

Impurities in plant water are replaced with hydrogen ions in the cation bed and hydroxyl ions in the anion bed. The hydrogen ions and the hydroxyl ions then combine to form pure water.

Figure 1 - Typical single bed demineralizer schematic

Mixed bed demineralizer

A mixed bed demineralizer is a demineralizer in which the cation and anion resin beads are mixed together. It is equivalent to a number of two-step demineralizers in series. In this type of demineralizer, more impurities are replaced by hydrogen and hydroxyl ions, and the water that is produced can be extremely pure. The conductivity of the produced water can therefore be 0.05 μS/cm or even less. Regeneration of a mixed bed demineralizer is generally more complicated than for a single bed demineralizer.

Figure 2 - Typical mixed bed demineralizer schematic