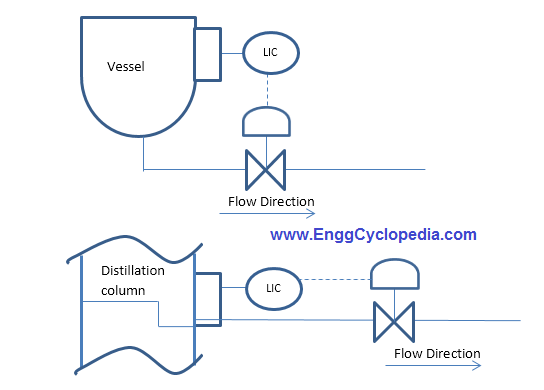

Level control valves are used to maintain liquid levels for different process equipment such as - Vessels, distillation column bottom section, distillation column side liquid draw, etc. in process industries. Maintaining specific liquid level is essential for the efficient and safe operation in process industry. These valves maintain the liquid level by regulating the liquid flow going into and out of the system.

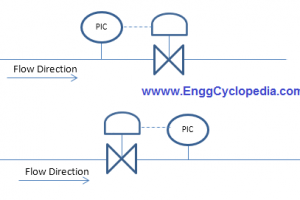

Liquid (or interface liquid) is in physical contact with gas or other liquid phase. Liquid is taken out from unit operations. Level measurement is done using level instruments and they send signal to a level controller. Controller compares the reading and gives inputs to throttle (open or close) the control valve.

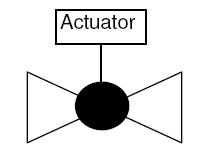

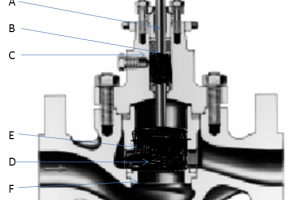

The level control valves consist of a floating mechanism, sensing element and control valve.

There are different types of floating devices used in the control valve to control the liquid level in the system. The two common types are float operated valves and diaphragm operated valves. In float operated valves float is used while in diaphragm operated valve diaphragm is used to adjust the valve according to the level in the tank or vessel.

Here the working mechanism of level operated valves is discussed.

- When the liquid level in the tank rises, floating device also attached to lever or rod also rise.

- This movement of the float is transmitted to the valve and the valve gets open or closed accordingly to allow or restrict the flow rate.

- When the liquid level reaches the desired set point valve position is adjusted to maintain the desire flow rate.

- If the liquid level rise above set point, valve gets closed to stop the liquid flow.

- Similarly, if the liquid level falls below the set point, the valve gets open to allow the liquid to flow till the liquid level reaches the desired set point.

Generally level control valve are found in liquid outlet line from vessel, liquid outlet from distillation columns, partial reboiler, partial condenser, flash vessel, separators, tank liquid outlet lines, etc.