A JT valve, short for Joule-Thomson valve, is an ingenious piece of equipment used for managing and controlling the temperature of gases during their expansion.

INDEX

What is a JT Valve?

How does a JT Valve work?

Applications

FAQs

What is a JT Valve?

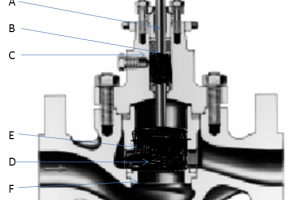

JT valve or Joule Thomson valve is name after the "Joule Thomson Effect" discovered by James Prescott Joule and William Thomson (Lord Kelvin), the JT valve plays a pivotal role in processes where maintaining specific temperature levels is crucial.

Joule Thomson effect suggests that rapid expansion of a real gas will cause it to rapidly cool down as well. A JT valve capitalizes on this effect to cool down a compressed gas by throttling its flow and causing rapid expansion.

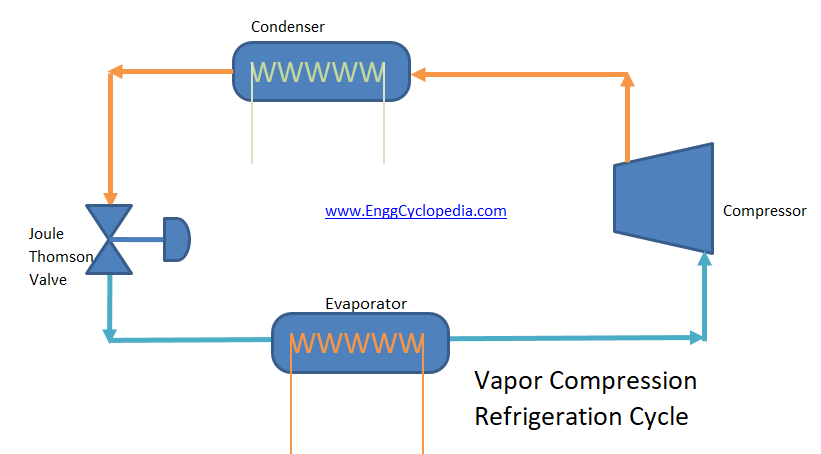

Therefore JT valves are commonly used in the vapor compression refrigeration cycle.

How does a JT Valve work?

Vapor compression refrigeration cycle works in following steps.

- Refrigerant is compressed to elevate its pressure, typically using a positive displacement compressor.

- This compressed gas is sent to a condenser to de-superheat and condense it to a liquid.

- The compressed and condensed refrigerant is throttled through a JT valve for Joule Thomson effect.

- Rapid expansion across the JT valve cools down the gas.

- The cooled refrigerant gas is sent to a heat exchanger (or evaporator) where it can be used to cool down other fluids such as, air, water or other services.

- In this process, the refrigerant itself gets heated.

- It is then collected and sent back to the compressor from step1. This way the refrigeration cycle continues.

Applications

JT valves capitalize on the Joule Thomson effect to enable refrigeration. Hence they are used in all kinds of different scenarios involving refrigeration.

- Rapid expansion of compressed refrigerant is the main cooling force in household ACs and refrigerators.

- In natural gas production, some of the gas is throttle across a JT valve to cool it down and to remove some condensate elements at this stage. Rest of the gas is then sent to the gas pipeline. This minimizes the possibility of condensation, two phase flow and slugging in the gas pipeline.

FAQs

1. What industries use JT valves?

JT valves are widely used in industries involving natural gas processing, petrochemicals, cryogenics, and refrigeration. They are instrumental in liquefied natural gas (LNG) production and the cooling of gases in various applications.

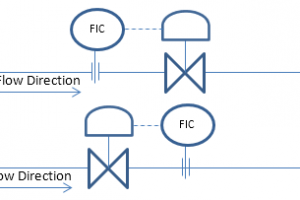

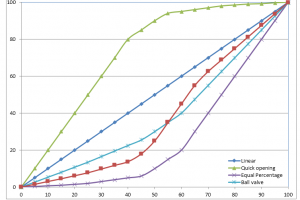

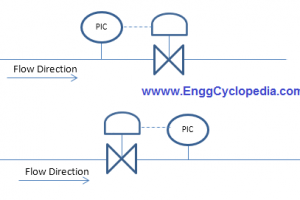

2. How does a JT valve differ from a regular control valve?

A JT valve specializes in temperature control during expansion, whereas a regular control valve primarily manages pressure. JT valves are designed to minimize temperature fluctuations, a crucial factor in several processes.

3. Why is temperature control important in gas processing?

In many processes, the quality and efficiency of gas operations depend on precise temperature control. For example, in LNG production, temperature control ensures gases remain in a liquid state, making them easier to transport and store.

4. Are there specific safety considerations for JT valves?

Safety is paramount when handling high-pressure gases. Proper design, installation, and maintenance of JT valves are essential to prevent leaks and ensure the safe operation of gas processing systems.

5. Can JT valves be used for all gases?

JT valves are effective for a wide range of gases but may not work optimally for every gas. Their performance depends on the gas's specific properties, so careful consideration is needed when choosing the appropriate valve.

6. What are the primary benefits of using JT valves?

The key benefits of JT valves include precise temperature control, energy efficiency, and reduced maintenance costs in gas processing systems. They are crucial for industries relying on controlled gas temperatures.