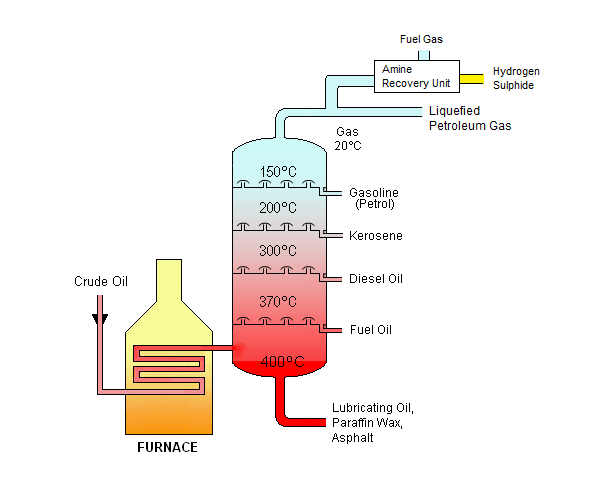

The vapors coming from the top of a distillation column are close to their initial dew point. These vapors contain mostly the light component and to some extent the heavy component from the mixture to be separated.

An overhead condenser, which is essentially a heat exchanger, cools down these vapors using a coolant stream usually cooling water. Being close to the initial dew point, the heavy component vapors are readily condensed while most of the light component still remains in vapor phase. The two phase mixture is sent to a reflux drum which provides residence time to enhance separation of light vapors from heavy liquid. This type of condensers is known as partial condensers, as the vapors are only partially condensed.

In another type of condenser, vapors may be completely condensed and taken out as product and fraction of this subcooled liquid can be recycled back to top of the column. This type of condensers is known as total condensers.

The liquid from reflux drum rich in heavy component is recycled back to the top of distillation column and the vapor phase rich in light component is separated as a product of continuous distillation process.