Gas lift is well simulation technique used in oil and gas industry to increase the production of crude oil from the well. In this technique gas is injected into the wellbore through a series of valves called gas lift valves to reduce the hydrostatic pressure of the column and lift the reservoir fluid to the surface. This post explores the structure of gas lift systems along with different types of it.

Table of content:

1. What is gas lift system?

2. How does gas lift work?

3. Types of gas lift

What is gas lift system?

Gas lift is an artificial-lift method for enhancing crude oil recovery from a reservoir. Gas lift systems serve several purposes, such as :

- Increasing production rates by reducing back pressure in the wellbore.

- Enhancing oil recovery from reservoirs with high water cut or low-pressure formations.

- Managing wellbore pressure to prevent fluid column separation and improve flow efficiency.

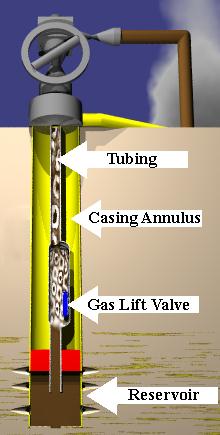

This systems typically consist of a gas source, such as a high-pressure gas line or a dedicated gas injection well, and a series of gas lift valves installed at specific intervals in the production tubing. These valves are controlled by pressure differences and open at predetermined pressures, allowing gas to flow into the tubing.

Components of a Gas Lift System

a. Gas Sources: Gas lift systems require a reliable source of gas to inject into the wellbore. This gas can be sourced from various options, including:

- Natural gas from a high-pressure gas line.

- Compressed air or nitrogen.

- Dedicated gas injection wells, especially in remote locations or offshore operations.

b. Gas Lift Valves: Gas lift valves are critical components of the system and are installed at specific intervals within the production tubing. These valves regulate the flow of gas into the wellbore.

Key types of gas lift valves include:

- Injection orifice valves: These valves control the flow of gas into the tubing, allowing gas to be injected at or near the bottom of the well.

- Reverse flow or annulus valves: These valves prevent well fluids from flowing back into the annulus, ensuring efficient gas injection.

Check detailed post on gas lift valve to learn more about it.

How does gas lift work?

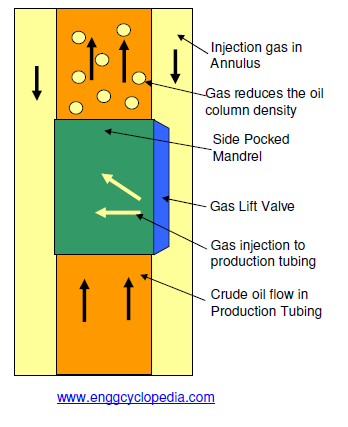

This method works by injecting the optimum amount of natural gas into the production tubing which transports crude oil from reservoir to the surface. The gas injected in the oil column reduces the effective density of oil in production tubing, thus reducing the hydrostatic pressure of the oil column in the well. The reduced pressure of the oil column above the reservoir allows the reservoir fluids to enter the oil well bore at a higher flow rate, thus enhancing the oil recovery from reservoir.

Usually the natural gas recovered along with the crude oil is used for the gas-lift. This gas is typically conveyed down the tubing-casing annulus surrounding the production tubing which contains the crude oil column flowing upwards.

Lift gas flows through the annulus around production tubing and enters the production tubing through gas-lift valves located in the gas-lift mandrel. The gas lift valves control the gas injection rate which has to be fixed based on wellbore conditions and properties of reservoir fluids.

Types of gas lift

Gas lift can be either continuous or intermittent, depending on the productivity of the concerned wells. Intermittent gas-lift method is used typically for low productivity crude oil wells.

1. Continuous Gas Lift

Continuous gas lift method is used typically to continuously maintain efficient production rates by enhancing the oil recovery by lowering the hydrostatic pressure of crude oil column in production tubing.

2. Intermittent Gas Lift

Intermittent gas-lift method for enhancing crude oil recovery is typically used for wells with low productivity to allow build up of oil in the wellbore by lowering the oil column hydrostatic pressure.

Gas-lift systems can be classified in another way based on the reuse of injection gas.

1. Rotational Gas Lift

If the gas recovered from oil is compressed and sent back for gas lift, this system is known as ‘Rotational Gas Lift’ systems. This is a closed system and uses a fixed amount of gas over and over again for lift. External supply of injection gas is not required for such systems.

2. Recoverable Gas Lift

In such gas-lift systems, the injection gas is supplied from an external source. Gas recovered is sent for commercial uses through a pipeline and not re-injected to production tubing for gas-lift.