Condenser is a type of heat exchanger that is specifically designed for condensing gaseous substances into liquid form by cooling. During the condensation process, the latent heat that was absorbed by the substance during its vaporization is released and transferred to the surrounding environment.

Condensers are an essential component in many industrial systems that require efficient heat rejection. By condensing gaseous substances into liquid form, they help to remove excess heat and prevent overheating, thereby maintaining the efficiency and reliability of the overall process.

Table of content:

How does the condenser work?

Types of condensers

Condenser vs Evaporator

How does the condenser work?

A condenser is a type of heat exchanger that is specifically designed to transfer heat from a working fluid, such as water in a steam power plant, to either a secondary fluid or the surrounding air. The condenser operates on the principle of efficient heat transfer that occurs during phase changes, specifically during the process of condensing a vapor into a liquid.

The vapor enters the condenser at a temperature higher than that of the secondary fluid, and as it cools, it reaches its saturation temperature and condenses into liquid, releasing large quantities of latent heat. This process continues along the length of the condenser, with the quantity of vapor decreasing and the quantity of liquid increasing, until only liquid remains at the outlet of the condenser. Some designs of condensers include an additional section to further cool the condensed liquid below its saturation temperature.

Compared to other cooling technologies, condensers have two major design advantages. First, heat transfer by latent heat is much more efficient than heat transfer by sensible heat alone. Second, the temperature of the working fluid remains relatively constant during condensation, which maximizes the temperature difference between the working and secondary fluid, leading to more efficient heat transfer.

Condensers come in countless variations in terms of design, with various design variables, such as the working fluid, secondary fluid, geometry, and material. Commonly used secondary fluids include water, air, refrigerants, and phase-change materials.

Types of condensers

There are three main types of condenser heat exchangers.

Air-cooled condensers

Air-cooled condensers use ambient air as the cooling medium to remove heat from the hot vapor.

Advantages: No water source is required, which can be beneficial in areas with water scarcity or where water treatment is difficult. They are relatively easy to install and maintain, and do not require a separate water treatment system.

Disadvantages: They are less efficient than water-cooled condensers and are affected by changes in ambient temperature and humidity. They also require more space than water-cooled condensers.

Applications: Air-cooled condensers are commonly used in small- to medium-sized refrigeration and air conditioning systems, as well as in outdoor applications where water is not readily available, such as power plants, chemical plants, and oil refineries.

Water-cooled condenser

Water-cooled condensers use water as the cooling medium to remove heat from the hot vapor. The water is circulated through the condenser and then discharged to a cooling tower or another water source.

Advantages: Water-cooled condensers are more efficient than air-cooled condensers and are less affected by changes in ambient temperature and humidity. They require less space than air-cooled condensers and can be used in both small and large systems.

Disadvantages: Water-cooled condensers require a source of water and a water treatment system to prevent corrosion and scaling. They are also more complex to install and maintain than air-cooled condensers.

Applications: Water-cooled condensers are commonly used in large-scale refrigeration and air conditioning systems, power plants, and industrial processes where a large amount of heat needs to be removed.

Evaporative condenser

Evaporative condensers use a combination of water and air to remove heat from the hot vapor. The hot vapor is circulated through a series of tubes while water is sprayed onto the tubes, which evaporates and removes heat from the vapor. The resulting warm, moist air is then discharged to the environment.

Advantages: Evaporative condensers are highly efficient and can provide significant energy savings compared to other types of condensers. They also require less space than water-cooled condensers and can be used in both small and large systems.

Disadvantages: Evaporative condensers require a source of water and a water treatment system to prevent corrosion and scaling. They are also more complex to install and maintain than air-cooled condensers.

Applications: Evaporative condensers are commonly used in large-scale refrigeration and air conditioning systems, as well as in industrial processes where a large amount of heat needs to be removed and water is readily available.

Condenser vs Evaporator

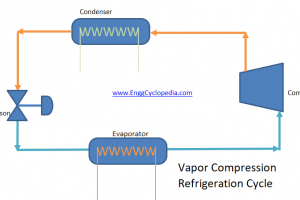

Condensers and evaporators are both types of heat exchangers that play opposite roles in a refrigeration cycle.

A condenser is a heat exchanger that is used to remove heat from a refrigerant gas and convert it back into a liquid state. The refrigerant gas is compressed and sent to the condenser, where it is cooled by a secondary fluid, such as water or air. As the refrigerant cools, it condenses back into a liquid, releasing the heat that it absorbed during the previous cycle.

An evaporator, on the other hand, is a heat exchanger that is used to absorb heat from a secondary fluid, such as air, and transfer it to the refrigerant. The refrigerant is allowed to expand in the evaporator, causing it to evaporate and absorb heat from the surrounding environment. The refrigerant vapor is then sent to the compressor to begin the cycle again.

In short, a condenser removes heat from a refrigerant gas and converts it back into a liquid, while an evaporator absorbs heat from a secondary fluid and transfers it to the refrigerant. Both components are crucial for the operation of a refrigeration cycle, and their efficiency can impact the overall performance of the system.