Pigs play a crucial role in the maintenance and inspection of pipelines across various industries. These cylindrical devices are designed to travel through pipelines, performing essential tasks such as cleaning, inspecting, and maintaining the integrity of the pipelines. In this post, we will explore the different types of pipeline pigs and their specific functions.

can be used to identify potential problems before they cause a failure.

Table of Content:

1. Pipe pigs

2. Pipe pig types

2.1. Utility pipe pigs

2.2. Inspection pig tool

2.3. Gel pig tool

Pipe pigs

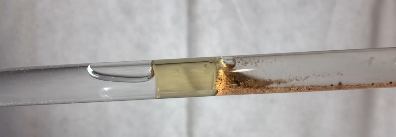

Pipe pigs (or pig tools) are capsule like objects used for cleaning of pipeline by pushing them through the pipeline using fluid pressure. The pipe is cleaned by brushing action from the pig tool. This cleaning process is called pigging. Pigging is also done for inspection of pipelines apart from cleaning pipelines.

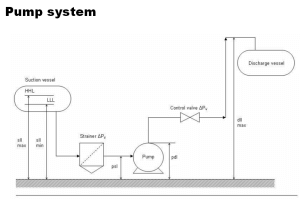

Pig receivers and launchers are also essential to the pipeline pigging process. The pipe pig is launched using a pig launcher at the beginning of the pipeline. The pig tool is pushed through the length of the pipeline by the upstream fluid pressure, cleaning the pipeline along the way. At the end of the pipeline, the pig is received in a pig receiver.

Pipe pigs are also used to separate different products in a multiproduct pipeline. Use of pipe pigs for separation between two products results in saving of product and time required for switching between two different products and line flushing. Use of pig tool instead of line flushing for cleaning of pipelines in between batch operations also translates to elimination of environmentally harmful cleaning agent liquids.

Pipe pigs are used for performing following types of tasks -

- Cleaning of pipeline and displacement of sludge

- Separation between batches of different products in the same pipeline

- Inspection tool for the pipeline

Pipe pig types

The type of pig to be used and its optimum configuration for a particular task depends on the purpose of pigging, contents in the pipeline and characteristics of the pipeline such as size, minimum bend radius, types of valves etc. Based on these factors a type of pig tool is chosen. Pipe pig types can be classified into following categories.

1. Utility pipe pigs

Utility Pigs are used for cleaning and product separation. Based on the utility or the purpose of the pig tool, these are classified into 'cleaning pig tools' used for cleaning and 'sealing or separation pig tool' used for separation between two products.

- Cleaning pigs are used to remove solid deposits, semi-solid deposits and debris. They are typically made of a soft material, such as foam, that can scrape against the walls of the pipeline and remove any dirt, scale, or other buildup. Cleaning pigs are typically used on a regular basis to keep pipelines running smoothly and efficiently.

- Sealing pigs provide an interface between two dissimilar products and also provide a good seal in order to sweep liquids. Sealing or separation pigs are used to prevent two different products from mixing. For example, a sealing pig might be used to prevent oil from mixing with water. Sealing pigs are typically made of a hard material, such as steel, that can create a tight seal between two sections of pipeline.

Based on the pig structure, utility pig tools are further classified as, 'foam pigs', 'mandrel pigs' and 'spherical pigs'.

Foam pigs are capsule shaped and made out of polymer foam. They are typically used in conjunction with cleaning pigs to remove any debris that the cleaning pig might have missed. Foam pigs are also used to dewater pipelines and to dry pipelines after they have been cleaned.

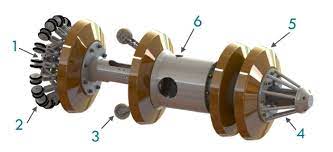

Mandrel pigs are dumbbell shaped with a central tube called 'mandrel'. Different kinds of components can be attached to this mandrel to customize the pig tool to suit different operations. For example, a mandrel pig might be used to carry a corrosion inhibitor through a pipeline.

Spherical pigs are either solid spheres made from polyurethane foam or inflatable spheres inflated using glycol and water. Spherical pigs are used to clean pipelines and to dewater pipelines. They are also used to measure the roundness of a pipeline.

2. Inspection pig tool

They are also known as 'intelligent pig tool' or 'smart pig tool'. They are used for inspection of the condition of the pipe and/or its contents. These pig tools are equipped with sensors for gathering various kinds of data, as the pig tool travels through the pipeline. The electronics and sensors on an intelligent pig tool are powered by batteries on the pig.

Magnetic flux leakage (MFL) pigs are used to detect surface pitting, corrosion of inner walls, cracks, and weld defects in pipelines. MFL pigs work by creating a magnetic field around the pipeline. Any defects in the pipeline will cause a disruption in the magnetic field, which can be detected by the MFL pig.

Some other intelligent pig tools use Electromagnetic acoustic transducers (EMAT) to detect pipe defects. EMAT pigs work by sending an electromagnetic pulse through the pipeline. Any defects in the pipeline will cause a change in the pulse, which can be detected by the EMAT pig.

Caliper pigs can measure the roundness of the pipeline to determine areas of crushing or other deformations. Caliper pigs have a series of sensors that measure the diameter of the pipeline at different points along its length. This information can be used to identify areas of the pipeline that need to be repaired or replaced.

3. Gel pig tool

Gel pigs are a series of gelled liquid systems which have been developed for use in pipeline operations, either during initial commissioning, or as a part of a continuing maintenance program. The gel helps to remove debris from the walls of the pipeline and to carry corrosion inhibitors and other chemicals through the pipeline.

Most pipeline gels are water-based, but a range of chemicals, solvents, and even acids can be gelled. Some chemicals can be gelled as the bulk liquid and others only diluted in a carrier. Gelled diesel is commonly used as a carrier of corrosion inhibitor in gas lines.

As a liquid, the gel can be pumped through any line which will accept liquids. Gel pigs can be used alone (in liquid lines), in place of batching pigs, or in conjunction with various types of conventional pigs. When used with conventional pigs, gelled pigs can improve overall performance while almost eliminating the risk of sticking a pig.

Gel pigs do not wear out in service like conventional pigs. They can, however, be susceptible to dilution and gas cutting. Care must be taken, therefore, when designing a pig train that incorporates gel pigs to minimize fluid bypass of the pigs, and to place a conventional pig at the back of the train when displacing with gas.