Evaporators are widely used in various industries such as food and beverage, chemical, pharmaceutical, and wastewater treatment. They are essential for concentrating and purifying liquids, recovering valuable products, and reducing waste. Evaporators come in different types and designs, and the choice of evaporator depends on the application and the specific requirements of the process.

Table of content:

What is an evaporator?

Types of evaporators

What is an evaporator?

An evaporator is a device used to remove liquid from a solution by converting it into vapor. This is achieved by applying heat to the solution. This causes the liquid to evaporate and leave behind a more concentrated solution or a solid residue. The vapor produced during the evaporation process can be condensed and collected as a separate product or disposed of.

In heat transfer equipment, an evaporator is a component in a refrigeration or air conditioning system that facilitates the transfer of heat from a low-temperature medium, such as the air in a room, to a high-temperature medium, such as the refrigerant used in the system.

The evaporator works by absorbing heat from the low-temperature medium, which causes the refrigerant to evaporate and turn into a gas. The refrigerant gas is then compressed and sent to the condenser, where it is condensed back into a liquid, releasing the heat it absorbed during the evaporation process. The condensed refrigerant is then sent back to the evaporator to repeat the process.

Types of evaporators

There are several types of evaporators used in various industries, each with its own advantages and limitations. The following are some common types of evaporators:

Natural Circulation Evaporator

In this type of evaporator, the circulation of the liquid occurs naturally, driven by the density difference between the hot liquid and the cooler liquid. Natural circulation evaporators are simple and easy to operate, but they are not suitable for highly viscous or fouling liquids.

There are two main types of natural circulation evaporators:

Long Tube Vertical Evaporator

This type of evaporator consists of a vertical shell and tube heat exchanger with a large number of long tubes mounted vertically inside the shell. The heated liquid enters the bottom of the evaporator and flows up the tubes due to natural circulation caused by the density difference between the heated and cooler liquid.

The vapor generated in the tubes is collected at the top of the shell and is usually condensed in a separate condenser. The concentrated liquid is then collected at the bottom of the evaporator.

Short Tube Vertical (Calandria) Evaporator

Short tube vertical evaporator is another type of natural circulation evaporator. It is similar to the long tube vertical evaporator, but it has shorter tubes that are usually less than two meters in length.

The short tubes minimize the residence time of the liquid and reduce the potential for product degradation due to prolonged exposure to high temperatures. They are also easy to clean and maintain, making them suitable for frequent product changeovers in small-scale operations. However, short tube vertical evaporators have a lower heat transfer rate than long tube vertical evaporators and may require longer processing times for highly concentrated products.

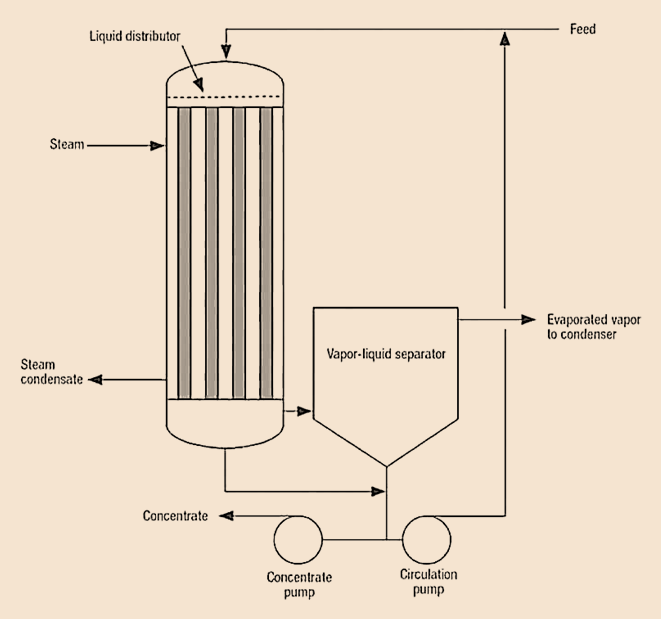

Forced Circulation Evaporator

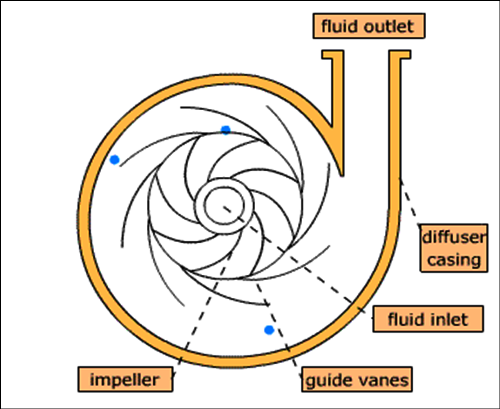

Forced circulation evaporators use a pump to circulate the liquid through the evaporator tubes or plates, which helps to overcome the limitations of natural circulation evaporators. Forced circulation evaporators can handle highly viscous or fouling liquids and achieve higher heat transfer rates, making them suitable for a wide range of applications.

Falling Film Evaporator

Falling film evaporators operate by allowing the liquid to flow down the inside of a vertical tube or plate, while the vapor is generated on the outside of the tube or plate. This configuration minimizes the contact time between the liquid and the heated surface, reducing the risk of fouling or scaling. Falling film evaporators are commonly used in the food and beverage industry.

Rising Film Evaporator

Rising film evaporators operate by allowing the liquid to flow up the inside of a vertical tube or plate, while the vapor is generated on the outside of the tube or plate. This configuration can achieve high evaporation rates and is suitable for highly viscous or fouling liquids.

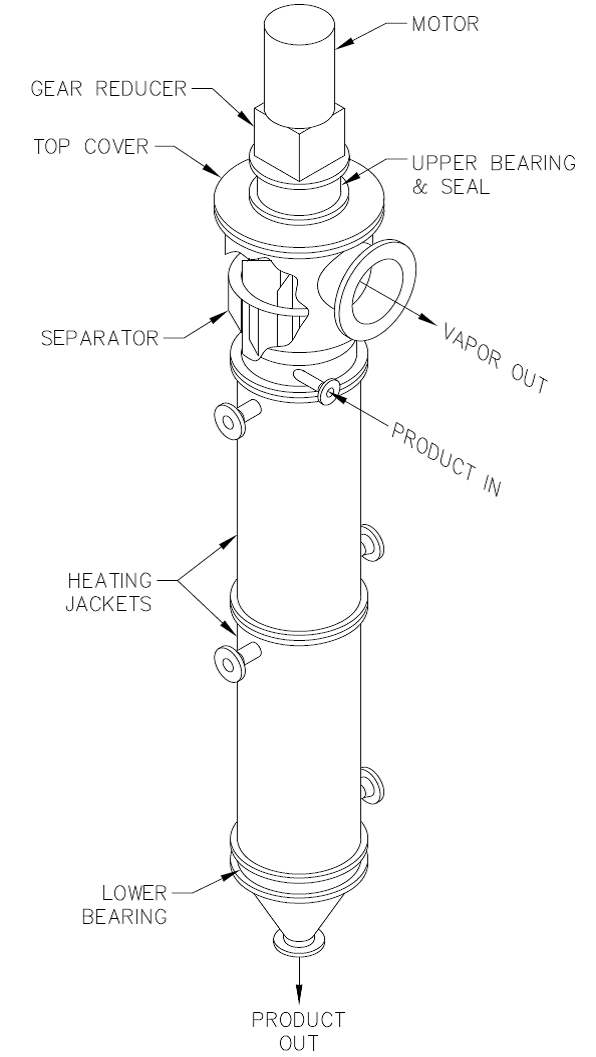

Agitated thin film evaporator

An agitated thin film evaporator is a type of evaporator that operates on the principle of creating a thin film of liquid on the surface of a heated cylindrical or conical surface. This type of evaporator is also known as a wiped film evaporator because it uses a wiping system to maintain a thin, uniform film on the heated surface.

The liquid is fed into the evaporator at the top and flows down the heated surface under the influence of gravity. The wiping system ensures that the liquid film is continuously renewed and that any fouling or scaling on the surface is minimized. The vapor generated by the heated surface is collected at the bottom of the evaporator and condensed in a separate condenser.

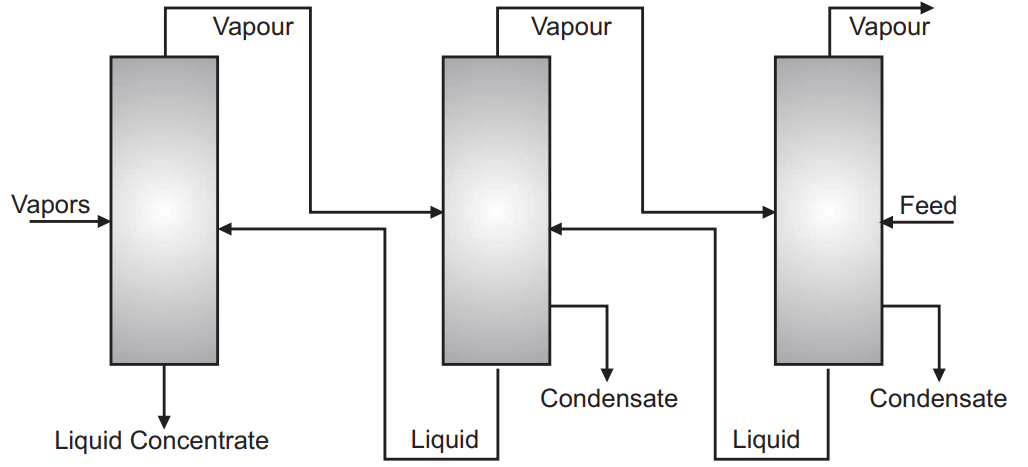

Multiple Effect Evaporator

Multiple effect evaporators use a series of evaporators in sequence, with each subsequent evaporator using the vapor generated by the previous evaporator as a heating source. This configuration can achieve high energy efficiency and is commonly used in industries where energy costs are a significant factor.