Pipes and various pipe fittings are most commonly classified based on their pressure temperature rating.

INDEX

Pipe / Pipeline Pressure Rating

What Is Pipeline Or Pipe Pressure Rating

Importance Of Pipe Pressure Rating

How Is Pipe Pressure Rating Determined?

Common Pressure Rating Standards

Common Units For Pipeline Pressure Rating

FAQs

Pipe / Pipeline Pressure Rating

The most common way of specifying pipe pressure temperature rating is given by ASME 16.5, using pound ratings (or lb ratings) - #150, #300, #400, #600, #900, #1500 and #2500. The pressure rating or pound rating for a pipe is determined using the design pressure and design temperature for the pipe.

What Is Pipeline Or Pipe Pressure Rating

Pipeline pressure rating refers to the maximum allowable internal pressure that a pipeline system can safely withstand without experiencing a rupture or failure. It is a critical factor in designing, constructing, and operating pipelines to ensure the safety and integrity of the system.

Importance Of Pipe Pressure Rating

The pressure rating is essential to ensure that a pipeline can handle the fluid or gas it transports without compromising safety. Exceeding the pressure rating can lead to catastrophic failures, leaks, and environmental hazards. As the design temperature increases the pressure rating requirement for the pipe also increases for the same design pressure.

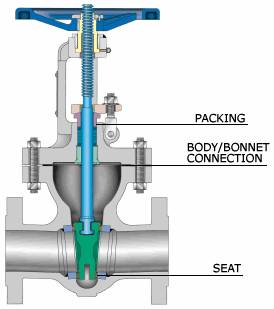

It should be noted that the pound rating for the whole piping system is equal to the pound rating of the weakest part, having the lowest pressure rating in the system. The weakest part may be any piping component or fitting which contains the pressure in the system and has the lowest pound rating due to any possible reasons.

How Is Pipe Pressure Rating Determined?

Pressure rating or pound rating of a pipe is dependent on the pipe material and design temperature. The pipe pressure rating for the same material changes at different temperatures. For the same material and constant design pressure, different pressure ratings are applicable over different ranges of design temperatures.

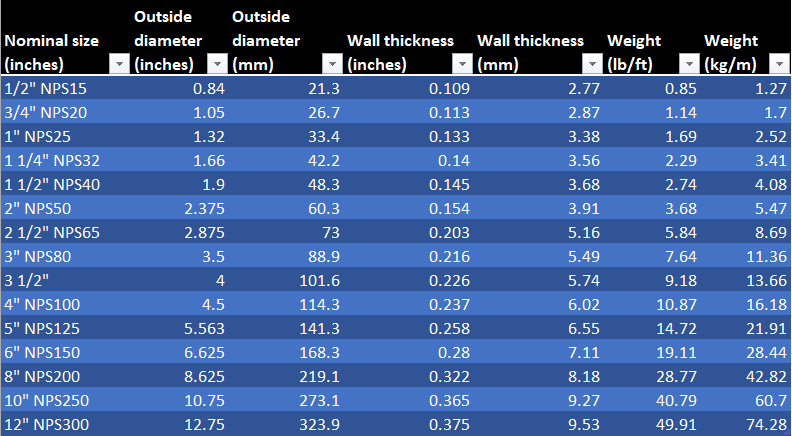

Pipe dimensions and weights of Schedule 40 stainless steel pipes based on ASME B36.19

Pipe dimensions and weights of Schedule 40 stainless steel pipes based on ASME B36.10pipe pressure rating as per ASME-B36.19

It is determined through various factors, including the material, wall thickness, and design specifications. Engineers use industry standards, material properties, and safety margins to calculate the maximum pressure a pipeline can safely withstand.

Common Pressure Rating Standards

Some common standards used for pressure rating include the American Society of Mechanical Engineers (ASME) B31.3 for process piping and the American Petroleum Institute (API) 5L for oil and gas pipelines. These standards provide guidelines for designing, constructing, and testing pipelines.

Common Units For Pipeline Pressure Rating

Pipeline pressure rating is usually expressed in units of pressure, such as pounds per square inch (PSI), megapascals (MPa), or bars. The pressure rating depends on the pipeline's material and application.

Among other methods of classification by using pressure temperature ratings is 'Pression Nominal' or 'Pressure Nominal' or PN number method. This PN number is a rough indicator of pressure rating in bar.

FAQs

1. Can Pipeline Pressure Rating Change Over Time?

Yes, the pressure rating of a pipeline can change over time due to factors like corrosion, erosion, and stress from operating conditions. Regular inspections and maintenance are necessary to ensure the pressure rating remains accurate.

2. What Happens if a Pipeline Exceeds its Pressure Rating?

Exceeding the pressure rating can lead to catastrophic failures, such as ruptures, leaks, and explosions. These incidents can result in property damage, injuries, environmental damage, and even loss of life.

3. How is Pipeline Pressure Rating Verified?

Pipeline pressure rating is verified through various methods, including hydrostatic testing, which involves filling the pipeline with water or another test fluid and pressurizing it to a level above its operating pressure to check for leaks or deformations. Non-destructive testing methods like ultrasonic testing are also used.

4. Can Pipeline Pressure Rating Vary Across Different Sections of a Pipeline?

Yes, the pressure rating of a pipeline can vary along its length. Different sections may have different materials, wall thicknesses, and operating conditions, which can affect the pressure rating. Engineers account for these variations during the design phase.

5. How Can Pipeline Pressure Rating be Increased?

Increasing the pressure rating of an existing pipeline may involve reinforcing the pipeline, replacing sections with higher-rated materials, or reducing operating temperatures. Such modifications should be done in compliance with relevant industry standards and regulations.

6. Who Regulates Pipeline Pressure Ratings?

Regulations and oversight of pipeline pressure ratings vary by region and industry. In the United States, for example, organizations like the Pipeline and Hazardous Materials Safety Administration (PHMSA) oversee pipeline safety and compliance with pressure rating standards.

7. Where Can I Find Information About a Pipeline's Pressure Rating?

Information about a pipeline's pressure rating should be available from the pipeline operator or owner. This data is typically documented in pipeline records and safety documents.

Please note that the information in this FAQ is for general guidance. Specific standards and regulations may vary by location and application. Always consult with qualified engineers, authorities, and industry standards when dealing with pipeline pressure ratings.

Among other methods of classification by using pressure temperature ratings is 'Pression Nominal' or 'Pressure Nominal' or PN number method. This PN number is a rough indicator of pressure rating in bar.

Pressure rating or pound rating of a pipe is dependent on the pipe material and design temperature.

The pipe pressure rating for the same material changes at different temperatures. For the same material and constant design pressure, different pressure ratings are applicable over different ranges of design temperatures.

As the design temperature increases the pressure rating requirement for the pipe also increases for the same design pressure.

It should be noted that the pound rating for the whole piping system is equal to the pound rating of the weakest part, having the lowest pressure rating in the system. The weakest part may be any piping component or fitting which contains the pressure in the system and has the lowest pound rating due to any possible reasons