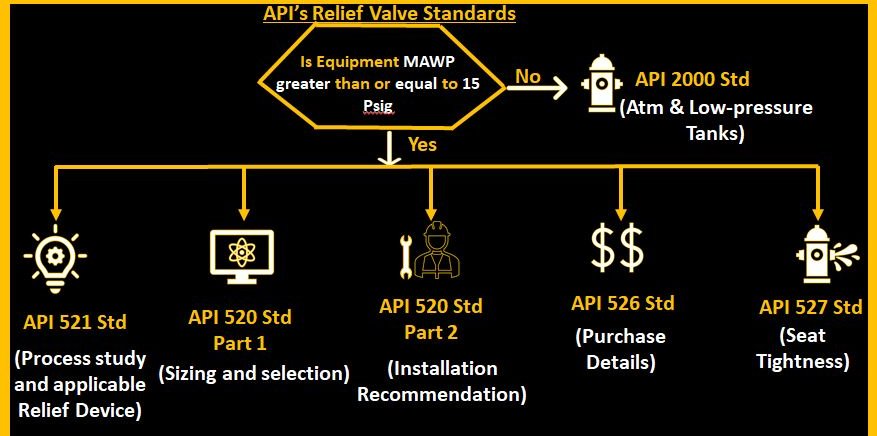

API standards are developed and maintained by American Petroleum Institute. API standards for pressure relieving systems provide guidelines and specifications for the design, manufacture, installation, and testing of pressure relief devices. Pressure relieving devices are used to protect equipment, pipeline or storage vessels from overpressure situations that could be lead to hazardous situation. This post explores few important API standards for pressure relieving devices.

Table of content:

1. API-520 Part I

2. API 520 Part II

3. API-521

4. API-526

5. API-527

6. API-576

7. API-2000

API-520 Part I

Title: Sizing, Selection, and Installation of Pressure Relieving Devices in Refineries - (Part I, Sizing and Selection)

This guide is used for sizing and selection of pressure relief devices used in petroleum related industries for equipment with maximum allowable working pressure (MAWP) of 15 psig greater. The document is intended for protection of unfired pressure vessels and equipment against overpressure from operation or fire. Pressure relief valves or rupture disks may be used independently or in combination with each other to provide the required protection against excessive pressure accumulation

API 520 part I covers the sizing and selection of pressure relieving devices such as safety valves and relief valves, for steam, vapor, gas and two phase service. This guide provides detailed methodology and equations for calculating relieving capacity and selecting the appropriate relief device.

API 520 Part II

Title: Sizing, Selection, and Installation of Pressure Relieving Devices in Refineries - (Part II, Installation)

This guide is used for the installation of pressure relief devices used in petroleum related industries for equipment with a maximum allowable working pressure of 15 psig greater.

API 520 Part II provides guidance on installation, inspection, testing and maintenance of pressure relieving devices. This guide outlines the necessary points need to be considered for proper installation of relief device. It also covers maintenance practices needed for safe operation of relief devices.

API-521

Title: Guide for Pressure relieving and Depressuring Systems (Petroleum petrochemical and natural gas industries)

This API standard specifies requirements and gives guidelines for determining overpressure causes, relieving rates for pressure relieving and vapor depressurizing systems in petroleum related industries. The standard also discusses selection and design of disposal systems, including such component parts as piping, vessels, flares, and vent stacks. API 521 also addresses safe depressurization of process equipment and systems in emergency shutdown situations.

API-526

Title: Flanged Steel Pressure Relief Valves

The standard covers specifications for flanged steel pressure relief valves (PRVs) by presenting basic requirements such as orifice designation and area, valve size, pressure rating, materials etc. for direct spring-loaded pressure relief valves and pilot-operated pressure relief valves.

API-527

Title: Seat Tightness of Pressure Relief Valves

This standard describes methods of determining the seat tightness of metal- and soft-seated pressure relief valves (PRVs). Seat tightness refers to the ability of a valve to prevent leakage fluid when it is in closed position. It covers various types of valves such as of conventional, bellows, and pilot-operated designs. This API also provides guidance on test methods.

API-576

Title: Inspection of Pressure-relieving Devices

Describes the inspection and repair practices for automatic pressure relieving devices commonly used in the oil and petrochemical industries. This API standard covers pressure relief valves, pilot-operated pressure relief valves, rupture disks, and weight-loaded pressure-vacuum vents, with regards to inspection and repair.

API-2000

Title: Venting Atmospheric and Low-pressure Storage Tanks Petroleum, petrochemical and natural gas industries—Venting of atmospheric and low-pressure storage tanks

Guide for normal and emergency vapor venting requirements for above ground petroleum and petroleum product storage tanks, above ground and underground refrigerated storage tanks. The tanks discussed in the document are designed for low pressures ranging from full vacuum through 15 psig. This API standard discusses causes of overpressure and vacuum, venting requirements, means of venting, selection,