Pressure relief valves ensure the safety and integrity of the process by relieving excess pressure and preventing catastrophic failure. Pilot operated pressure relief valve is important type of pressure relief valve as it offers several distinct advantages over other types of relief valves in various applications. These valve contain smaller self actuated pilot valve to control the operation of larger main valve. This feature enables them to handle situations with significant back pressure.

Table of content:

1. What is pilot operated valve?

2. How pilot operated valve works?

3. Advantages

4. Disadvantages

What is pilot operated valve?

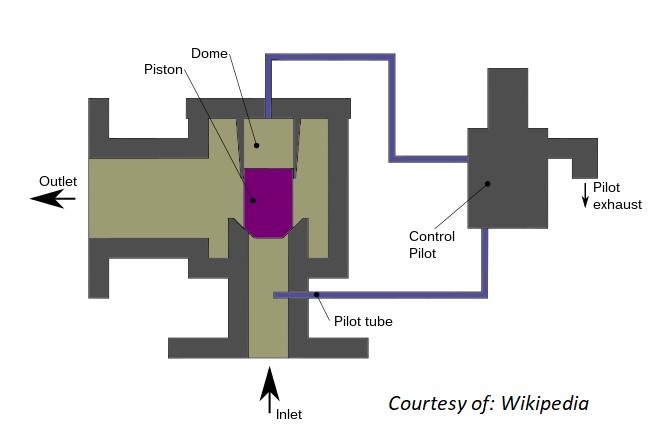

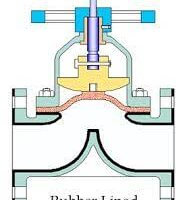

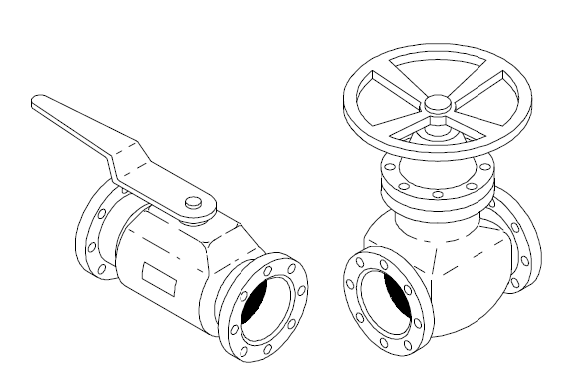

Pilot operated pressure relief valves are designed to handle significant back pressure in critical conditions. These valves utilize the combination of pilot valve with main valve to relieve pressure. In pilot operated setup, main relief valve is combined with and controlled by a smaller self actuated pilot valve.

In pilot operated setup, main relief valve is combined with and controlled by a smaller self actuated pilot valve. The pilot valve is connected to the process fluid which circulates through the valve. The pressure of the process fluid determines force applied to pilot valve's disc. The main valve is usually larger than pilot valve and it is responsible for relieving excess pressure from the system. The opening and closing of main valve is determined by pressure and flow of the process fluid received from pilot valve.

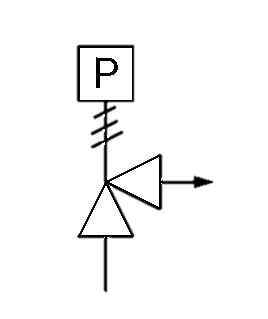

The control mechanism is the major difference between pilot operated valve and spring loaded relief valve. Conventional relief valves use spring to control opening of the valve. While pilot operated valves use process fluid circulated through pilot valve to open the valve disc.

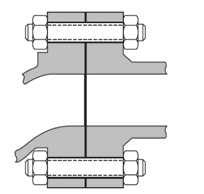

The absence of a spring in the main valve enables pilot-operated relief valves to operate within narrow pressure margins. The force applied by the process fluid directly corresponds to the system pressure, resulting in accurate and responsive pressure relief. This characteristic is particularly beneficial in applications where tight pressure control is required to safeguard the equipment and maintain optimal operating conditions.

How pilot operated valve works?

The working mechanism of pilot operated relief valves involve pressure exerted by the pilot valve to control the valve opening of the main valve. The working procedure of pilot operated relief valves is explained in this section.

- The pilot valve senses the pressure of the process fluid.

- As the process fluid increases, it exerts force on valve's disc.

- This compresses spring within the pilot valve. This force is transmitted to main valve. The force applied by the process fluid is proportional to the pressure, ensuring that the main valve opens and closes in response to the system's pressure conditions.

- When the pressure exceeds the set point, the pilot valve opens, allowing the process fluid to flow through and control the operation of the main relief valve.

- Conversely, when the pressure drops below the set point, the pilot valve closes, causing the main valve to close as well.

Advantages

- Precise pressure control

- Able to handle high pressure drops

- Effective in high back pressure situations

- Wide range of set pressure options

Disadvantages

- Risk of blockage

- Sensitive to process fluid characteristics

- Require frequent maintenance