Progressive cavity Pumps

Progressive cavity pumps are unique among positive displacement pumps for their ability to pump a wide range of fluids. Such as clean, water-like liquids, delicate products such as maraschino cherries and viscous, solids-laden fluids are all appropriate applications for progressive cavity pumps. The progressive cavity pump is a positive displacement pump which can produce pressures that may cause the bursting of vessels or pipes. The power transmission train (shaft, coupling rod, joints and rotor) of the pump may be overloaded thus resulting in damage or breakage. Also the pump housing parts with their connections may be overloaded and break. Never run the pump against a closed inlet or outlet valve.

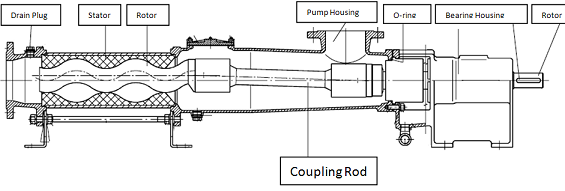

The displacement of progressive cavity pump is proportional to the number of strokes, cycles or revolutions. The similarity of progressive cavity pumps to other positive displacement pumps ends there, however. The simplest progressive cavity pumps have a single threaded screw, called the rotor, turning inside a double threaded nut called the stator (Figure 1)

Progressive cavity pump start-up procedure for the first time start-up

- Fill the pump with medium. In the case of high viscosity media fill with a liquid. Pump priming is vital to ensure lubrication of the rubber stator.

- Fill the piping on the pump suction side. In anti–clockwise rotation only:

- Fill the pump housing.

Starting-up

The progressive cavity pump design requires strict attention to the following:

- Never run the progressive cavity pump dry. A few rotations in dry condition will damage the stator!

- Open valves and vents before starting the pump.

- Check the direction of rotation by briefly switching on the pump motor.

Using progressive cavity pump in food industry

When a pump has been supplied for a food application it is important to ensure that the pump is clean prior to initial pump operation.

The cleaning of the pump, before use on food, can be executed in two ways:

A) By dismantling the pump components and manual cleaning of these parts using suitable detergents. No dirt contamination must enter anew during re–assembly.

B) By applying a C.I.P. (Cleaning In Place) procedure provided the type and execution of the pump suit such a procedure.

A clean in place treatment on the pump should be executed at the following times:

- When the pump is first commissioned for use.

- When any spare components are fitted into the wetted area of the pump.

- After operations, i.e. before a fairly long idleness of the pump.

- After longer idleness, before re–operation. Many companies have their own C.I.P. procedures which suit to their pumping media, but if you are unsure that your C.I.P. procedure is suitable for the pump supplied then please contact the pump manufacturer.

Following video explains the criteria of progressive pumps.

Progressive cavity pump