Flanged Ends Connections for Valves

Flanges are usually installed on valves larger than DN50 (2’’). For sizes smaller than DN50 (2’’), threaded-type valves are typically used, depending on the application and safety considerations: for example at steam lines, even for sizes below DN50 (2’’), welded type valves are used instead of threaded type ones.

The main advantage of using a flanged valve is that the valve can be easily removed from the line. However, it is to be noted that flanges are subject to thermal distortion and shock. Therefore a welded connection would be usually recommended for applications where significant temperature variations occur.

Flanges are generally built to ANSI Standard B16.5 (or DIN or other international standards). Rating of flanges is made according to the type of service, material requirement, maximum service temperature and pressure.

The following three (3) major valves flanged ends connections are mostly in use nowadays:

• Flat face (FF)

• Raised face (RF)

• Ring type joint (RTJ)

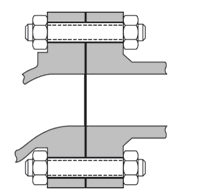

Flat Face Flange Connection

Flat face flanges allow full contact between the two mating flanges and the flange gasket (a gasket is installed between the flanges in order to seal the connection). They are mostly used with low-pressure applications, like for example in cast iron flanges. Due to the fact that both flanges are in full contact with each other, this design keeps help flange stresses to a minimum. However, a disadvantage of this type of flanges is that the flange faces will have to be completely flat in order to properly seal across the entire flange.

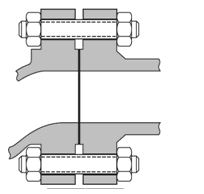

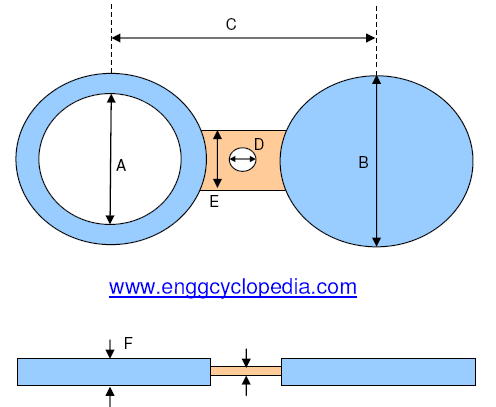

Raised Face Flange Connection

The Raised face is the most common of all flange faces. The Raised face is named like this because the gasket surfaces are raised above the bolting circle face (the raised face is only a slight step). Raised face flanges are therefore not full contact flanges. As such, some flange stress may be created when the bolting is tightened. The raised face is finished with a series of concentric circular grooves for keeping the gasket in place and providing a better seal. Raised face flanges are specified for low, medium and high pressure-temperature applications.

Ring Type Joint Flange Connection

Ring type joint flanges are actually a modification of the raised face design. RTJ flanges have grooves cut into their faces with steel ring gaskets. RTJ flanges are usually specified for high pressure and high temperature applications.