The following example demonstrates how heat exchanger bypass can be effectively used for temperature control for a heat exchanger.

Question

Design a heat exchanger to handle following three operating scenarios at different times.

Shell side fluid – Water to stripper column inlet

Tube side fluid – Hot water from stripper outlet

Heat exchanger design should consider following three operating cases.

(A)Water shellside flow = 100,000 kg/hr

Inlet shellside pressure = 5.0 barg

Inlet shellside Temperature = 25 degC

Outlet shellside temperature = 40 degC

Water tubeside flow = 100,000 kg/hr

Inlet tubeside pressure = 6.0 barg

Inlet shellside Temperature = 75 degC

Outlet shellside temperature = 60 degC

Exchanger heat duty = 6.65 X 106 kJ/hr

(B)Water shellside flow = 150,000 kg/hr

Inlet shellside pressure = 5.0 barg

Inlet shellside Temperature = 25 degC

Outlet shellside temperature = 40 degC

Water tubeside flow = 100,000 kg/hr

Inlet tubeside pressure = 6.0 barg

Inlet shellside Temperature = 75 degC

Outlet shellside temperature = 60 degC

Exchanger heat duty = 9.97 X 106 kJ/hr

(C)Water shellside flow = 100,000 kg/hr

Inlet shellside pressure = 5.0 barg

Inlet shellside Temperature = 25 degC

Outlet shellside temperature = 40 degC

Water tubeside flow = 50,000 kg/hr

Inlet tubeside pressure = 6.0 barg

Inlet shellside Temperature = 75 degC

Outlet shellside temperature = 60 degC

Exchanger heat duty = 6.65 X 106 kJ/hr

Solution

From the problem statement for heat exchanger design, it is clear that the operating case (B) is the most demanding case in terms of heat duty of the exchanger. Hence, the exchanger should be designed to satisfy this operating case.

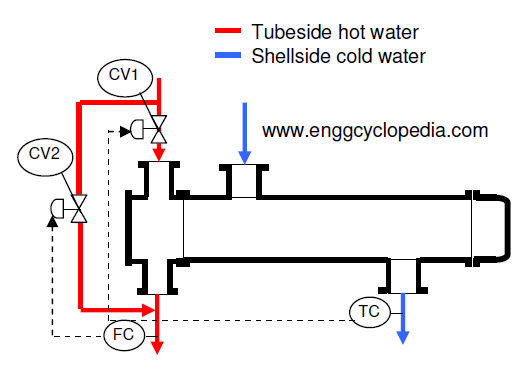

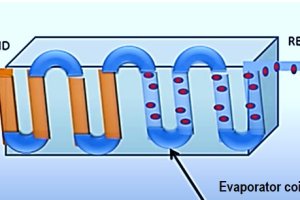

If the exchanger is designed for case (B), then for cases (A) and (C), there is excess hot water flow on the tubeside, than what is required. This excess flow can result in overheating of the tubeside water flow. To avoid this overheating, one possible solution is to install a bypass on the hot water flow side of the heat exchanger, as shown in the schematic.

There are various possible control schemes for the hot water on shellside, depending on the variables to be controlled.

- The outlet temperature of shellside cold water can vary widely depending on the ratio of flowrates on hot and cold side. Hence to maintain the same tubeside outlet temperature, this flow ratio needs to remain the same. Since the tubeside flow is excess than the requirement, only part of the flow needs to go to the exchanger tubeside and rest can bypass the exchanger. The temperature controller (TC) on exchanger shellside outlet throttles the control valve (CV1 in exchanger schematic) to adjust the fraction of hot water going to exchange tubeside.

- On hot water side of the exchanger (tubside) either temperature of total flow of hot water outlet can be controlled by adjusting the bypass line flow using control valve (CV2 in exchanger schematic). In the present arrangement flow control on the total hot water flow is considered. Since the fraction of hot water flowing through heat exchanger tubeside is already controlled for shellside outlet temperature control, the fraction of hot water through bypass is adjusted to maintain the same total hot water flow on the exchanger outlet side. In this case the temperature of this combined stream cannot be controlled.

- If the temperature on hot water outlet is to be controlled, then the control valve on tubeside bypass line (CV2 on schematic) can be used to adjust the bypass flow. The total flow of hot water will vary in this case, but the temperature can be maintained in a desired range.

This sample problem goes on to show how a single exchanger can be designer to accommodate, multiple operating cases. The solution is to design the exchanger for the most demanding case in terms of exchanger heat duty and to use a bypass line on the excess flow side of the exchanger to control different process parameters.