NFPA 12 is perhaps the most widely accepted standard for the design, installation, operation and maintenance of fire fighting systems using carbon dioxide as the extinguishing medium. This standard deals with two (2) types of systems:

- high pressure systems: In these systems, carbon dioxide is stored in pressure containers (cylinders) at ambient temperatures. High pressure systems are mostly used nowadays.

- low pressure systems: In these systems, carbon dioxide is stored in pressure containers at a controlled low temperature of 0 degF (or -18 degC). Low pressure systems are used in special applications, especially when we want to maximize the density of fire fighting medium per storage space, like for example for fire-fighting purposes of gas turbines enclosures.

Due to its toxicity, carbon dioxide is not to be used in normally occupied spaces like offices, libraries, computer rooms etc. However, it is widely used for fight fighting purposes in unoccupied and/or remote switchgear rooms, battery rooms, data rooms, cable tunnels.

Things to consider during design of a carbon dioxide fire fighting system

After we determine which areas will be fire protected with carbon dioxide, we must estimate the most probable type of fire that will develop upon fire initiation. Based on NFPA 12, two (2) major types of fire exist:

- surface fires

- deep-seated fires

Surface fires are relatively easy to extinguish. They are mostly fires which are caused by flammable solids, gas or liquids.

On the other hand, deep-seated fire are more difficult rivals. Deep-seated fires are mostly smoldering fires, like for example a cable fire. Bigger quantities of carbon dioxide are necessary for their extinguishment compared to surface fires, since exposed material will also have to be cooled to a temperature that will not allow its re-ignition.

Once we have decided the type of fire, we can proceed to calculate the necessary quantities of carbon dioxide.

For this purpose, we must calculate the net volume of the protected space. This calculation does not normally take into consideration false ceilings and/or false floors.

Carbon dioxide requirements for surface fires

Once the net volume is known, we proceed to determine the design concentration of carbon dioxide that is required for the type of flammable material involved. In no case shall a concentration less than 34% be used. Design concentrations are typically calculated by adding a safety factor of 20% to the minimum concentration factors shown at Table 5.3.2.2 of NFPA 12, i.e. design concentration = 1,2 * minimum concentration

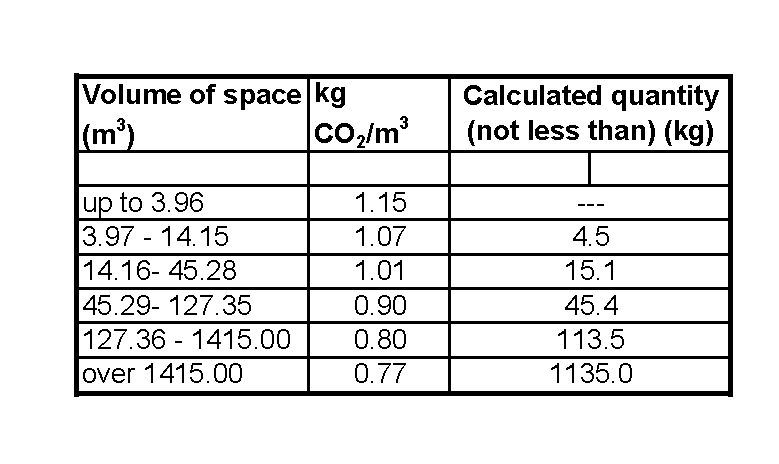

For a design concentration of 34%, NFPA 12 stipulated flooding factors will have to be applied as a minimum:

Picture 1 - Carbon dioxide volume factors for surface fires

We take note that the smaller a space, the bigger the necessary quantity of carbon dioxide. For materials requiring a design concentration bigger than 34%, the quantities calculated until now will have to be multiplied with the volume factor given in Figure 5.3.4 of NFPA 12

Minimum calculated quantities will have to be increased in order to take into consideration any of the following reasons:

- openings that cannot be closed

- ventilation systems that cannot be shut down during carbon dioxide discharge

- a small percentage of carbon dioxide is vaporised during discharge without contributing to the putting out of the fire

Although no specific rules exist, it is usual that minimum calculated quantities are multiplied by a factor of 1.1 in order to take into consideration all these parameters.

Carbon dioxide requirements for deep-seated fires

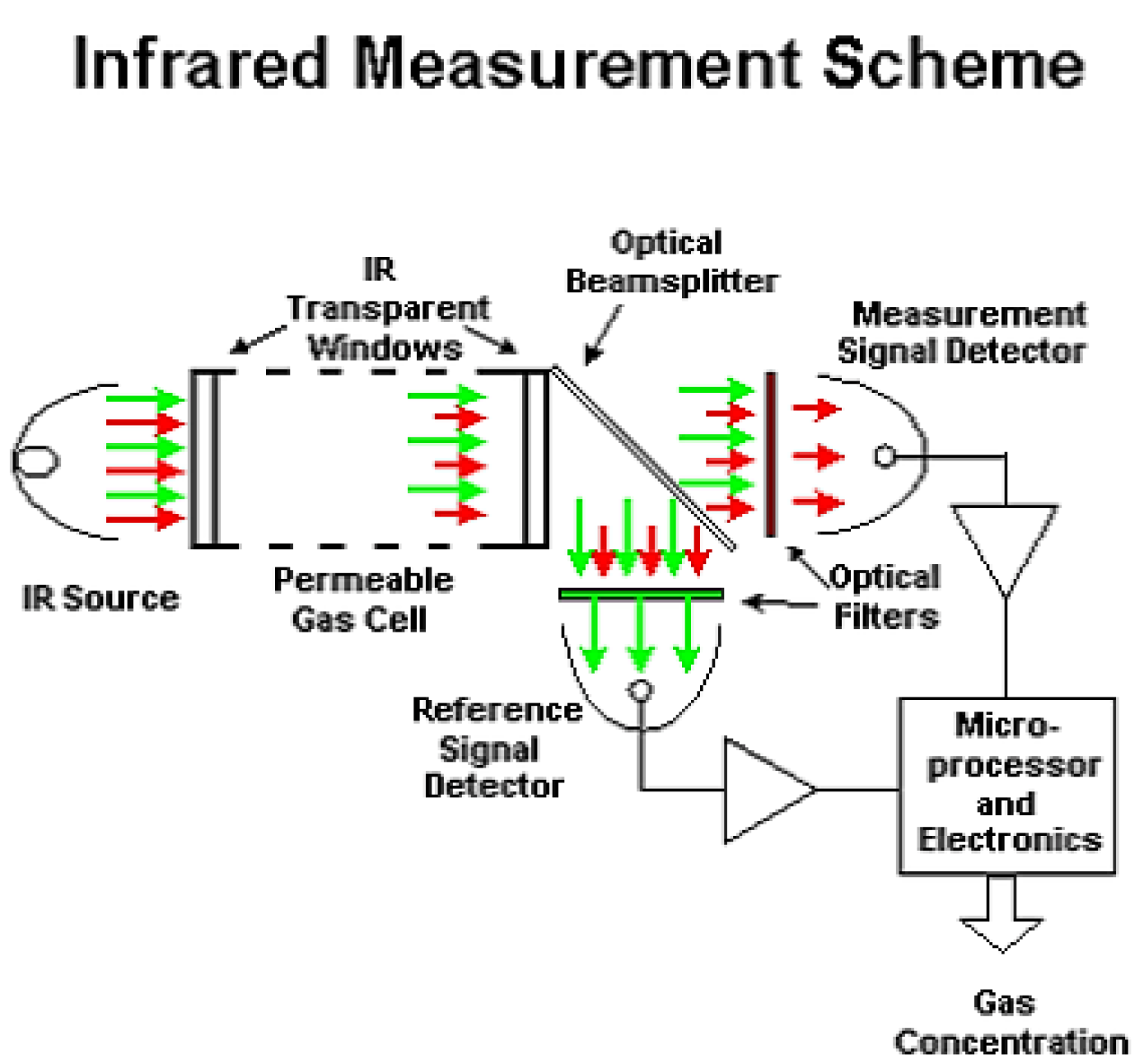

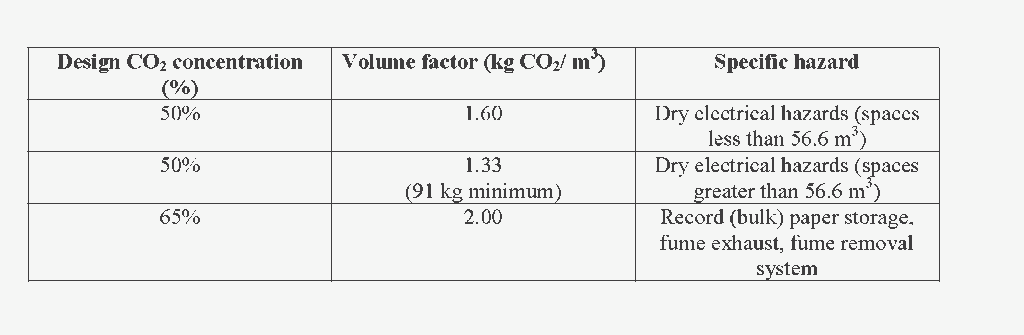

Here, the calculation is more straight-forward. Knowing the protected space net volume, we use the volume factors of Table 5.4.2.1 of NFPA 12

Picture 2 - Design carbon dioxide concentration for deep-seated fires

Additional safety factors, similar to surface fires are also used here in order to take into consideration uncloseable openings, ventilation systems that cannot be shut down etc.

Selection of number of cylinders

Individual cylinders shall be used having a nominal weight capacity of 5, 10, 15, 20, 25, 35, 50, 75, 100, or 120 lb (2.3, 4.5, 6.8, 9.1, 11.4, 15.9, 22.7, 34.1, 45.4, or 54.4 kg respectively).

Depending on the calculated quantities of carbon dioxide that is necessary for each space, we proceed to order the final amount of carbon dioxide cylinders for all protected spaces, taking into consideration the following:

- For redundancy reasons, overall selected amount of carbon dioxide cylinders is divided in two (2) banks of cylinders: the main bank of cylinders and the reserve or auxiliary bank of cylinders.

- Calculation of the overall amount of cylinders is not done by adding the number of necessary cylinders per space, since it is very unlikely that a fire develops simultaneously in all spaces. If for example, space A needs seven (7) cylinders, space B needs ten (10) cylinders and space C needs fifteen (15) cylinders, then we shall order thirty (30) cylinders, 15 for each bank so as to cover the worst case scenario: fire outbreak at space C.