This article focuses on the most common types of double (dual) seals used for centrifugal pumps, in accordance with API 682 and ISO 21049 standards.

Single Seal or Double Seal ?

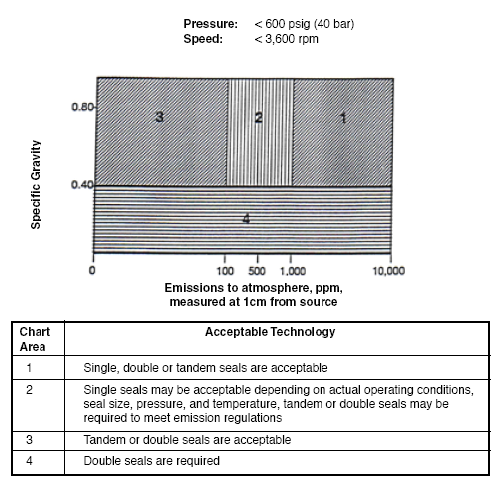

The decision to use double mechanical seal instead of single mechanical seal is not easy. Many parameters influence this decision. However in general, most pumps handling fluids with low specific gravity values (e.g. 0.4 or less) and having to meet strict emission regulations for Volatile Organic Compounds (VOC) are likely to be equipped with double (dual) type mechanical seals. The table below can serve as a rough guideline. In any case, user will have to consult both pump and mechanical seal manufacturers before reaching a final conclusion.

Table 1 - Indicative table on when to use double mechanical seals

Common types of double (dual) seals

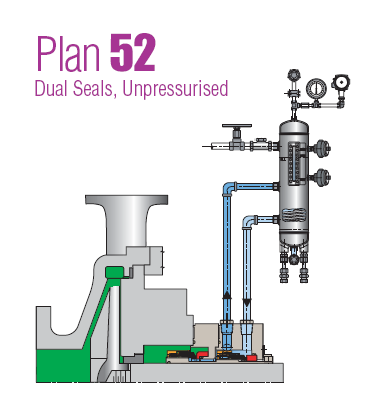

API Plan 52:

Plan 52 uses an external reservoir for providing buffer fluid for the outer seal of an unpressurised dual seal arrangement. Cooling coils in the reservoir are available for removing heat from the buffer fluid.

Picture 1 - Plan 52 typical configuration

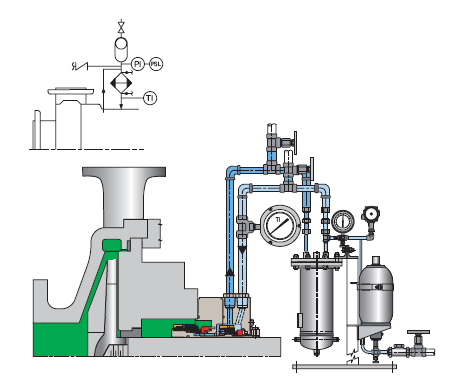

API Plan 53A:

For Plan 53A, reservoir pressure is produced by a gas, usually nitrogen. A pumping ring maintains circulation during operation. Thermosiphon action is in effect during standstill. Reservoir size can be optimised in accordance with the flow rate. Any particles tend to settle at the bottom of the reservoir and don't get recirculated. Similar to Plan 52, cooling coils are also used. Proper safeguards against the backflow of barrier fluid into the external supply of nitrogen also need to be considered.

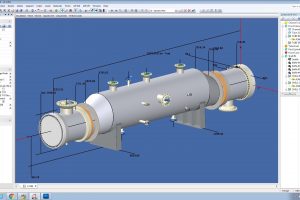

API Plan 53B:

Plan 53B makes use of an accumulator for isolating the pressurizing gas from the buffer fluid. A heat exchanger is also included in the loop in order to cool the fluid. It can either be water cooled, finned tubed, or air-cooled, depending on the system heat load.

Picture 2 - Plan 53B typical configuration

API Plan 53C:

Plan 53C makes use of a piston accumulator for maintaining the pressure and compensating for any fluctuations.

API Plan 54:

Plan 54 employs an external source for providing a clean pressurised fluid. Plan 54 systems can be custom-made so as suit various application requirements and provide pressurised flow to various seal installations, thus keeping costs down.