Pump mechanical seals are devices which keep or seal the pumped fluid in the pump casing, thus avoiding leakages and costly loss of pumped product. Since approximately 1950s, mechanical seals have almost totally eliminated inefficient and costly gland packings. They are installed at the place where the pump shaft enters or leaves the casing. There are various styles, configurations and sizes of mechanical seals. However, all of them employ the basic principle of stationary and rotating face combinations.

How a pump mechanical seal works

A mechanical seal works though the use of two very flat lapped faces which make it difficult for leakage to occur. One face does not rotate with the shaft (stationary), whereas the second one rotates with the shaft (rotary).

As the faces rub together, a fluid film migration between the 2 faces is applied for cooling and lubrication purposes. The pumped fluid will ideally weep between the faces, entering as a liquid and remaining until it is vaporised as it reaches atmosphere.

It must be pointed out at this point that all mechanical seals leak some very small amounts of vapor and consequently, even with the best mechanical seal design, a small portion of the pumped fluid is lost.

Pump mechanical seals components

All mechanical seals are typically made of three basic sets of components:

1) A set of primary seal faces: one that rotates and one that remains stationary.

2) A set of secondary seals known as shaft packings and insert mountings, such as O-rings, PTFE or Grafoil wedges, or V-Rings.

3) Various hardware like gland rings, collars, compression rings, pins, springs, retaining rings and bellows.

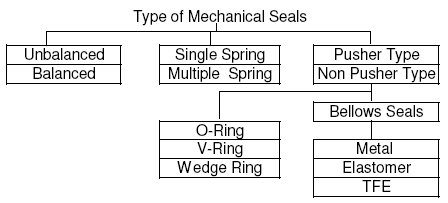

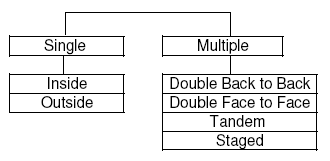

In general, there are various types of mechanical seals. In terms of design and arrangement, mechanical seals are generally divided into the following categories:

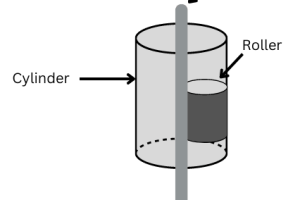

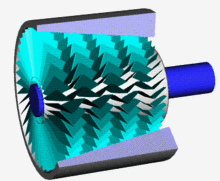

Picture 1 - Mechanical seals classification by design

Picture 2 - Mechanical seals classification by arrangement

Types of mechanical seals

Inside seals: An inside seal is designed in such a way that the rotary portion of the mechanical seal is located inside the pump seal chamber. With inside seals, the fluid and pressure are exerted on the outside diameter (O.D.) of the seal. Typically, inside seals are used for higher pressure applications compared to outside seals.

Outside seals: An outside seal is designed in such a way that the rotary portion of the mechanical seal is located outside the pump seal chamber. Quite often, outside seals are applied for chemical service in non-metallic parts: the pumped fluid does not come in contact with the metal parts of the seal and as a result, the need for expensive and/or exotic materials is often eliminated.

Pusher seals: A pusher seal is a design which pushes a dynamic secondary seal, which is either an o-ring, wedge or other type of equipment, across the shaft as a means of compensation for face wear and/or shaft movement.

Non-pusher seals: This type of seal is designed in such a way that the dynamic secondary seal is not used. Typically, non-pusher seals are metal bellows or elastomeric bellow seals.

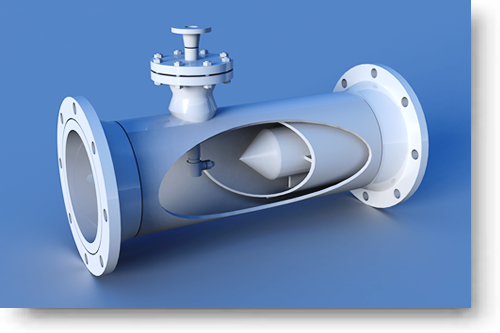

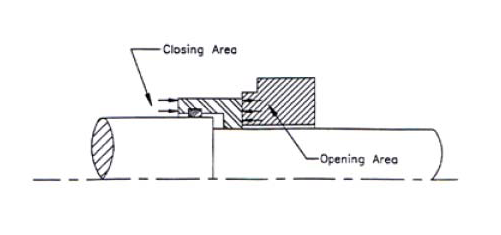

Balanced seals: At balanced seals, the hydraulic pressure which acts to close the seal faces is significantly reduced. Balanced seals present the advantage of generating less heat because of the reduced pressure forcing the faces together. Consequently, they can withstand much higher pressures compared to unbalanced seals.

Picture 3 - Balanced mechanical seal

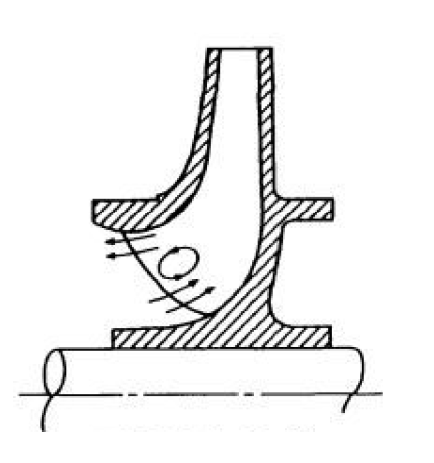

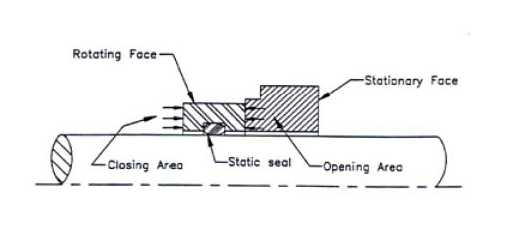

Unbalanced seals: At unbalnced seals, the full hydraulic pressure of the seal chamber acts to close the mechanical seal faces, without any reduction whatsoever. Unbalanced seals are intended for use only in low-pressure applications.

Picture 4 - Unbalanced mechanical seal

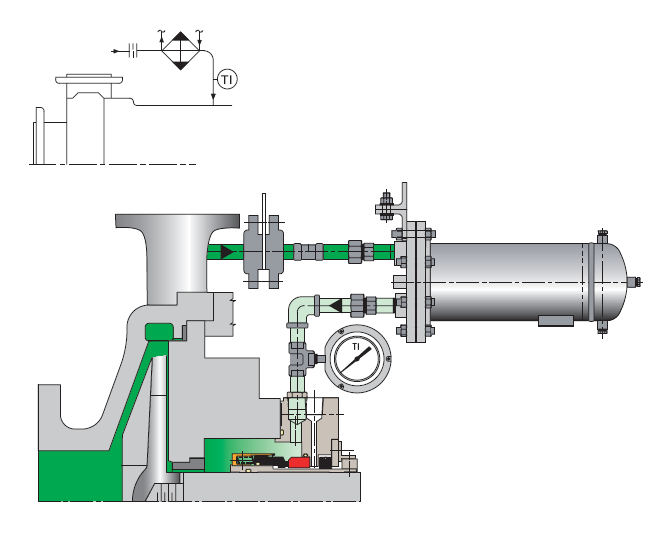

Double seals: In this arrangement, two (2) mechanical seals are used face to face, back to back or in tandem (facing the same direction), thus allowing a buffer fluid or gas to be introduced between the two sets of seal faces. Double seals are mostly used for the purpose of sealing a product that is a volatile organic compound, dirty,non-lubricating, or very viscous. Also, they are used for products that solidify or otherwise change state.

Click the button to check the most common types of pump seal piping plans for single seals.

Check the given article to study the most common types of double (dual) seals used for centrifugal pumps, in accordance with API 682 and ISO 21049 standards.