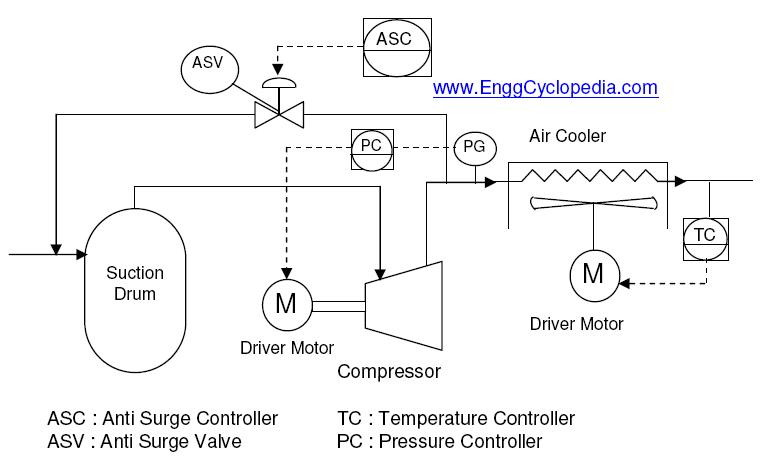

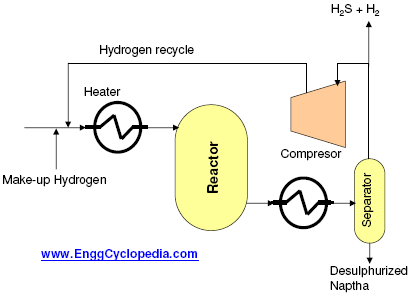

The following figure-1 represents a typical process flow diagram (PFD) for a centrifugal compressor system. Common equipments included in such systems are compressors, driver motors or turbines, suction knock out drums (KOD) to remove traces of liquid from the gas going into the centrifugal compressor and aftercoolers which help lower the temperature of the discharge gas from compressor. Often anti-surge controllers along with anti-surge valves are also part of this system to avoid operating the compressor at surge conditions.

A centrifugal compressor is typically driven by an electric motor or a steam turbine. The sample PFD in figure-1 indicates use of an electric motor. The driver motor or turbine is connected to the compressor by a shaft which can rotate at different speeds for which the motor or turbine is designed. Compressor manufacturer creates a ‘compressor map’ which is essentially a graph of compressor curves plotted at different rotational speed (RPM) values. For a given value of gas flow though the compressor, discharge pressure of can be controlled by controlling the rotational speed of the driver. Hence a pressure controller installed on the compressor discharge stream, sends a signal to the driver motor or turbine to control the rotational speed. Sometimes a compressor performance controller can be used which takes into account a lot of other parameters than just the discharge pressure, to effectively maintain the rotational speed.

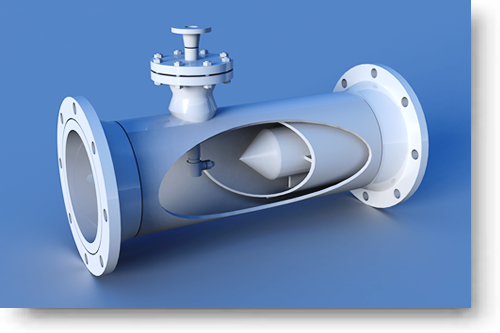

Presence of small liquid droplets in the gas compressor can be damaging to the compressor. Hence Knock Out Drums (KOD) at compressor suction are desirable to remove even small traces of liquid droplets from gas going to the compressor. These compressor suction drums may be equipped with demister pads and wire mesh to improve the efficiency of liquid droplet removal.

When gas is compressed the gas temperature also rises along with its pressure, since there is not enough time to vent the heat to atmosphere. Often high temperatures of the compressed gas are not desirable hence air coolers can be installed at the compressor discharge to enable temperature control of the discharge gas. These are known as compressor aftercoolers.

Compressor surge is seen as a very dangerous and detrimental phenomenon for compressor systems, because it causes the compressor to vibrate and damages the compressor parts. Compressor surge occurs due to high back pressure on the compressor discharge so that very small gas flow can be pushed through. This is indicated by a surge line on any compressor map. To avoid compressor surge the back pressure at compressor has to be lowered so that more gas flow can be circulated through the compressors. This can be accomplished by an anti-surge controller which opens the anti-surge valves so that excess pressure from the compressor discharge is vented to the compressor suction KOD. The anti-surge valves also enable more gas flow to be circulated through the system, avoiding prolonged compressor operation in the surge conditions.