Superheated steam

Superheated steam is the steam available at a higher temperature than its dew point or saturation temperature at the corresponding pressure. Steam available at its dew point temperature is in equilibrium with condensing water droplets and this steam is known as saturated steam.

The term superheat corresponds to the excess heat given to saturated steam to increase its temperature beyond dew point or saturation temperature of steam at that corresponding pressure. Normally in chemical or oil & gas process plants, available steam is at superheated conditions.

Steam desuperheater operation

Sometimes the high temperature of the superheated steam is not desirable and it may be required to desuperheat the available steam to its dew point or saturation temperature. Steam desuperheater is used to take out the excess heat from steam to bring down the steam temperature to saturation level. Desuperheaters are available in following two broad categories.

Indirect contact type

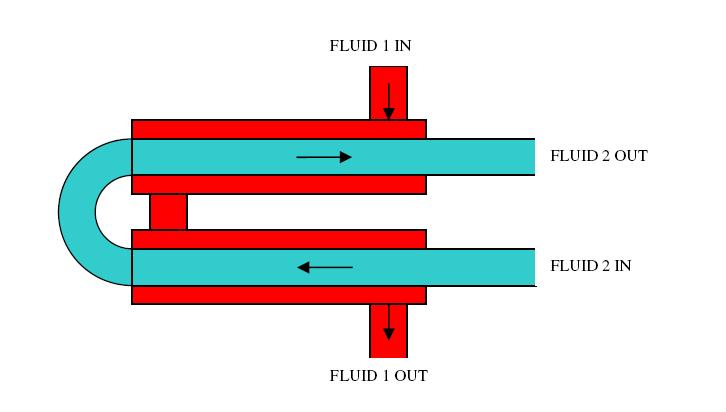

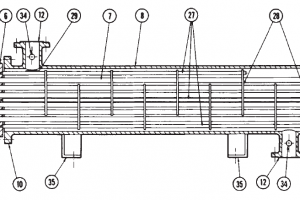

As the name suggests, in this type of desuperheaters, there is no direct contact between steam and the cooling medium. Shell and tube exchangers can be used as indirect contact desuperheaters, with superheated steam on one side of the exchanger and cooling medium on the other side. The temperature of the desuperheated steam could be controlled by either the inlet superheated steam pressure or the flowrate of the cooling water. Control of the superheated steam is not normally preferred and cooling medium flow is normally used to control the temperature of desuperheated steam. This is because the steam in this case is the main process fluid and cooling water is the utility - which should be easier to control. Cooling medium can be any colder fluid for example air or cooling water.

Direct contact type

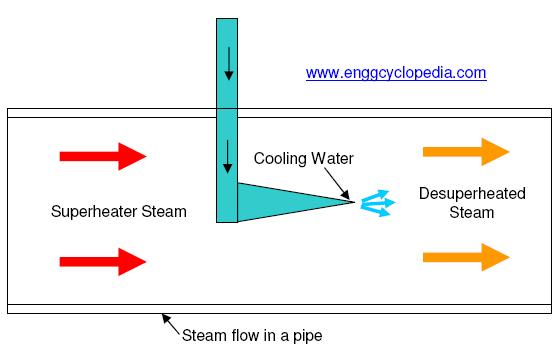

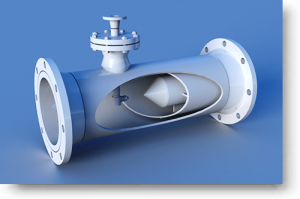

The cooling medium is in direct contact with the superheated steam in direct contact desuperheaters. Normally, the cooling medium is the same fluid as the vapour to be desuperheated, but in the liquid state. For example, in the case of steam desuperheaters, cooling water is used. The cooling water is mixed with the superheated steam using a spraying nozzle arrangement shown in the figure. Cooling water evaporates using the excess heat from superheated steam, thus reducing the steam temperature. Generally the set temperature at the desuperheater outlet is kept 3°C above that at saturation level. The set temperature is achieved in the desuperheater by using flow control over the cooling water.