In accordance with NFPA 25, a fire hydrant is a valved connection on a water main having a purpose to supply water to various fire protection apparatus, fire hose or other.

There are four (4) major types of hydrants mainly in use nowadays:

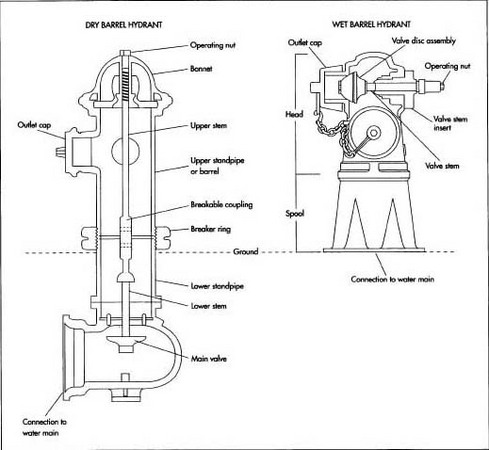

Dry barrel fire hydrant

This is probably the most common type of hydrant used today: it is equipped with a control valve below the frost line between the foot piece and the barrel. A drain connection is provided at the bottom of the barrel above the control valve seat for proper drainage. They shall be inspected annually and after each operation.

Monitor nozzle fire hydrant

A fire hydrant equipped with a monitor nozzle capable of delivering more than 946 L/min (250 gpm). They shall be inspected semi-annually.

Picture 1- Typical monitor nozzle fire hydrant

Wall fire hydrant

A hydrant mounted outside of a wall of a building, supplied from interior piping, and equipped with control valves installed inside the building which are usually key-operated from the building’s exterior. They shall be inspected annually and after each operation.

Picture 2 - Typical wall fire hydrant with multiple valves

Wet barrel hydrant

A hydrant normally used where there is no danger of freezing weather. Each outlet is provided with a valved outlet, properly threaded in order to be connected to a fire hose. They shall be inspected annually and after each operation.

Picture 3 - Typical dry barrel and wet barrel hydrant

Points to be considered about fire hydrants

In accordance with NFPA 25, user shall take care of the following:

- Hydrants shall be tested annually to ensure proper & reliable operation: full flow shall be maintained for at least 1 minute and check for any leakages. After operation, dry barrel and wall hydrants shall be observed for proper drainage from the barrel.

- All monitor nozzles shall be moved throughout their full range annually to ensure proper operability.

- Hydrants as well as monitor nozzles shall be lubricated annually to ensure that all stems, caps, plugs, and threaded parts are in good condition.

- A hose house shall be installed close to a hydrant. A hose house is a typical metallic enclosure housing all necessary hydrant auxiliaries, like hose nozzles, hose wrenches, gaskets and spanners. Hose houses shall be maintained annually and inspected quarterly.

Picture 4- Typical hose house for outdoors installation.