Flare tip burn back and its causes

Flare tip burn back is caused by low exit velocities of the gas at flare tip. The flare tip and flare stack diameter are designed handling for the maximum possible flow in the flare network.

However, the normal gas flow in the flare stack is much lower than the design flow rate, resulting in low exit gas velocities at the flare tip. Low gas velocities mean that the gas begins to burn much closer to the flare tip than desired, thus causing burn back of the flare tip.

Purge gas to avoid burn back of flare tip

To avoid burning back of the flare tip high gas exit velocities at the flare tip can be achieved by having a continuous high flow of purge gas in the flare stack. Normally continuous purging of gas is used to avoid air ingress. But the purge gas flow requirement to prevent flare tip burn back is much higher than the purge gas flow needed simply to avoid air ingress.

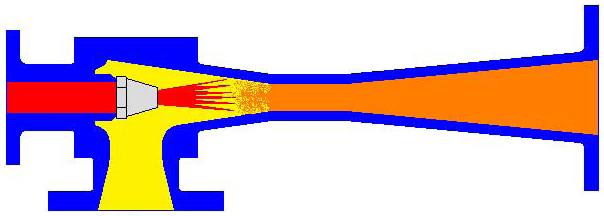

Use of sonic tip of to avoid flare tip burn back

High exit velocities can also be achieved simply by changing the design of flare tip. Sonic flare tip ensure the gas flow in the flare tip at MACH 1, which corresponds to the speed of sound.

Use of sonic flare tip also helps to ensure smokeless flame at the flare tip while avoiding burn back. A possible drawback of using a sonic flare tip is high pressure drop across the flare tip for design flow rates. Hence, use of sonic flare tip results in high design pressures for flare knock out drum and flare network.