Besides liquid ring vacuum pumps (LRVPs), another common vacuum generating device is the steam-jet air ejector or steam ejector.

Basic steam ejector structure

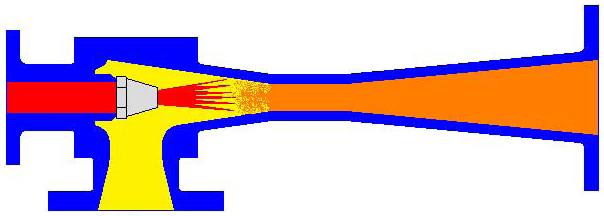

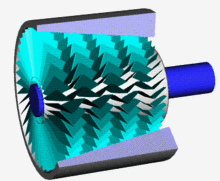

A steam ejector basically comprises of three (3) elements: a nozzle, a mixing chamber and a diffuser.

A high pressure motive fluid, typically steam, enters the steam ejector and passes through the nozzle. Through this nozzle, its velocity increases and consequently low pressure exists at that point on nozzle. This low pressure draws the suction fluid, typically air, into the mixing chamber where it mixes with the motive fluid. The mixture then passes through the diffuser. There, the mixed fluid expands, its velocity is reduced and its pressure is increased, resulting in recompressing the mixed fluids by converting velocity energy back into pressure energy.

Figure 1 - Typical steam ejector (single stage)

Types if steam ejectors

There are basically two types of steam ejectors: single-stage and multi-stage. Single-stage ejectors typically discharge at or near atmospheric pressure and are used for suction pressures ranging from atmospheric pressure to around 100 mbara.

Multi-stage ejectors are typically used when lower suction pressures are necessary. Steam consumption in multistage steam ejectors is relatively high as each stage must handle the load and motive steam of the stage ahead of it.

Advantages of steam ejectors

The major advantages of steam ejectors are listed as follows:

- Low investment costs compared to liquid ring vacuum pumps: no motor is necessary, no water-gas separator needs to be installed and no seal water cooler is required.

- No moving parts, therefore maintenance costs can be kept low.

- Compact construction and easy installation.

- Corrosion / erosion resistant as ejectors can be constructed from various materials so as to handle even corrosive fluids.

- High vacuum capability at high suction loads.

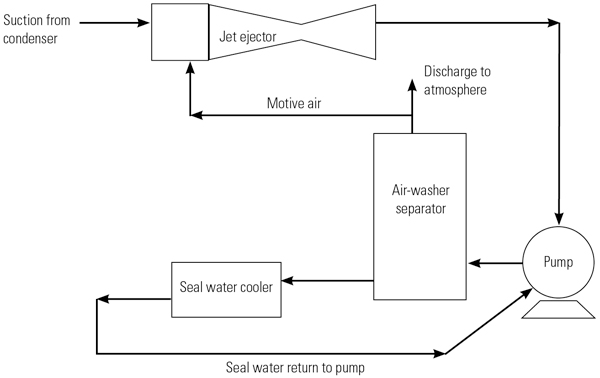

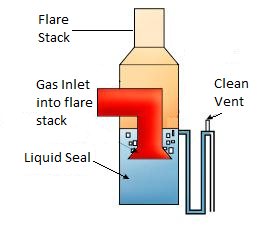

Hybrid air ejectors

A new development in steam ejectors technology is the advent of hybrid air ejectors. This is actually a combination of an air jet ejector and a vacuum pump. The air ejector is installed at the suction of the vacum pump, thus boosting its suction pressure and thus reducing the capital-investment cost for this pump. This first-stage ejector also helps minimize pump cavitation, as the pump no longer operates at low suction pressures, which could lead to vaporization of the seal liquid in the pump casing.

Figure 2 - Typical hybrid air ejector

Disadvantages of steam ejectors

Perhaps their biggest drawback is the fact that they need a steam supply in order to operate. When a steam source if difficult to find, then usually a motorised liquid ring vacuum pump (LVRP) has to be used.

Compared to LRVPs, they generally require a bigger number of motorised valves to operate properly, thus their control is usually more complicated. In general, motorised valve needs to be installed at every steam and air terminal point in order to allow the proper automation of evacuation process.