What is the Material Selection Diagram (MSD)?

The Material Selection Diagram (MSD) is an engineering drawing which shows material selection information and specification of the piping and equipment in a process unit/facility. MSD is normally developed from simplified Process Flow Diagrams (PFDs) by Process Engineer, Material Engineer and the metallurgist of project. The Material Engineer uses the Material Selection Diagram to assign a line class/specification to each line on the Piping and Instrumentation Diagram (P&ID) or Process Engineering Flow Scheme (PEFS).

What the Material Selection Diagram (MSD) show?

A typical Material Selection Diagram (MSD) normally indicates following items:

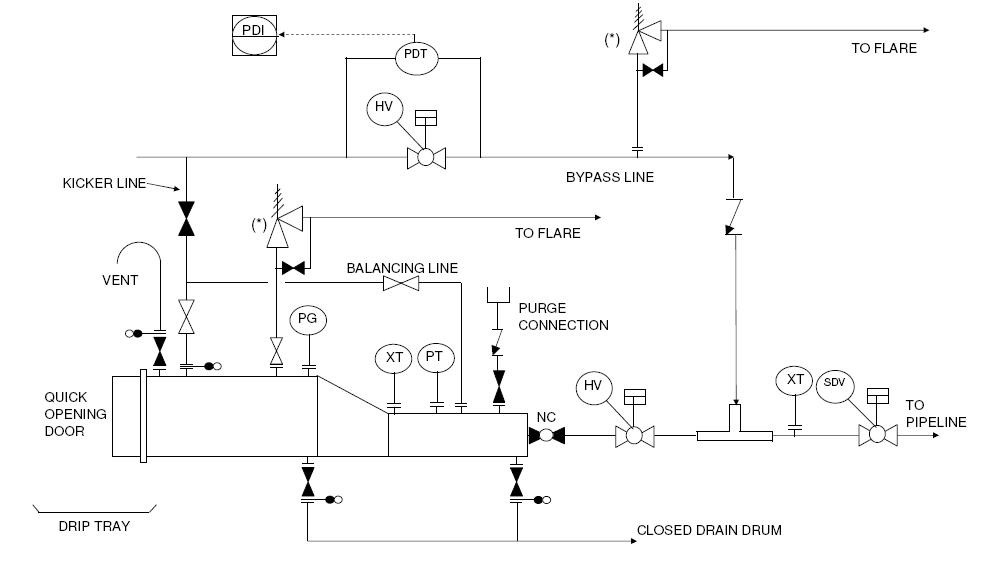

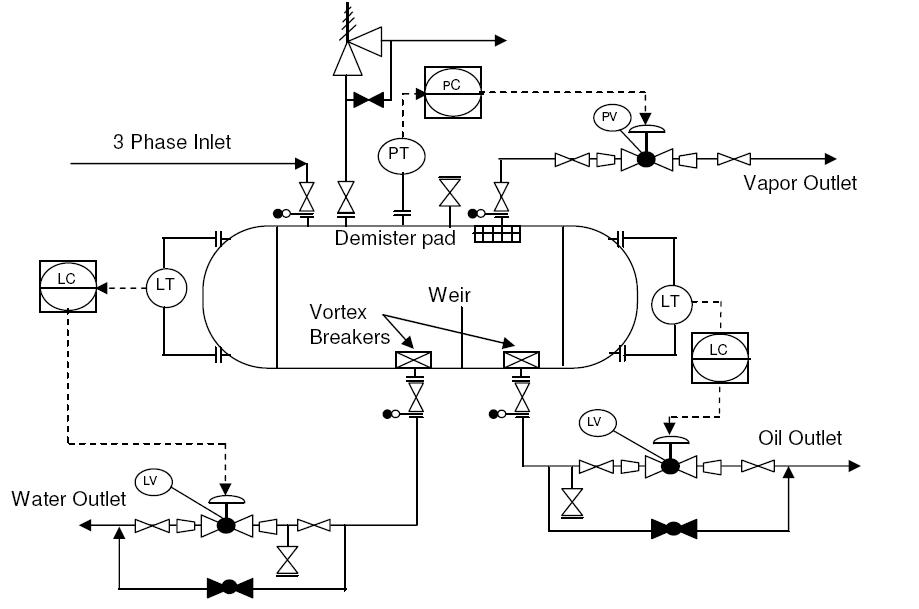

1. Important equipments in a facility such as pumps, compressor, heater, piping, specific valves, etc.

2. Specify material selected for each of the following equipment and piping itmes

- Columns : shell, internals, tray, lining

- Heat exchanger: shell, channel, tubes, tubesheet, lining

- Air Fan Cooler: headers, tubes, fins

- Tanks: shell, roof, bottom, internals

- Pipeline

- Valve

- Furnaces: coils (convection, radiant, steam), refractory

- Pumps: casing, impeller, pump material group

3. Following material/fabrication requirements are also normally indicated on a Material Selection Diagram (MSD)

- Corrosion allowance

- PWHT or Stress Relieving

- Wet sour service requirements

- Hardness limitation

- Specific impact test requirements (i.e. MDMT, etc.)

4. Following optional information can also be indicated on a Material Selection Diagram (MSD)

- Process data: design/operating

- Corrosion control and monitoring information

- Corrosion Monitoring Probes/Methods - location & type

- Chemical Injection - location & type

- Sampling points

- Cathodic protection - location & type

- Materials Balances

- percentage of severe corrosive components (e.g. H2, S, H2S, CO2, HF, chloride, etc.)

- Partial pressure of Severe Corrosive Components (e.g. H2, H2S, NH3, HCl, etc.)

- Detail information for spec break in piping (i.e. at valves, tee, cross, dead leg, etc.)

- Specific Notes (e.g. upset condition, short notes for corrosion control, etc.)

- References