Steam has been a popular mode of conveying energy since the industrial revolution. Steam networks are used for generating power, used in process industries such as sugar, paper, fertilizer, refineries, petrochemicals, chemical, food, synthetic fibre and textiles. The following characteristics of steam make it so popular and useful to the industry:

- High specific heat and latent heat

- High heat transfer coefficient

- Easy to control and distribute

- Cheap and inert

Properties of steam

Water can exist in the form of solid, liquid and gas as ice, water and steam respectively. If heat energy is added to water, its temperature rises until a value is reached at which the water can no longer exist as a liquid. We call this the "saturation" point or bubble point and with any further addition of energy, some of the water will boil off as steam. This evaporation requires relatively large amounts of energy, and while it is being added, the water and the steam released are both at the same temperature. Equally, if steam is made to release the energy that was added to evaporate it, then the steam will condense and water at same temperature will be formed.

Different physical properties of steam such as density, specific heat, enthalpy, entropy etc. are determined by temperature and pressure conditions. You can quickly refer to steam tables to obtain this properties by looking up a steam table for given temperature and pressure.

Temperature and pressure conditions for steam for different applications

The pressure and temperature of the steam to be generated in the steam system is influenced by a number of factors such as:

- Process requirements

- Equipment costs

- Distribution piping costs

- Boiler feed water treatment costs

- Steam turbine driver costs

The material of construction for equipment and piping is affected by the design pressure and temperature of the system. Below 650 psig, 750°F, carbon steel can be used for piping, tubing, steam turbine casings, etc. Above this temperature and pressure Cr-Mo alloy must be used with a corresponding increase in equipment cost.

If the steam is being used to generate electrical power, higher pressures and superheat temperatures are desirable since steam turbines are more efficient at the temperatures and pressures. Higher pressures and temperatures at the turbine inlet also help to prevent wet turbine exhaust conditions which can lead to severe erosion of the turbine blades. Moisture contents of less than 8 to 9% in the exhaust of condensing turbines is usually specified by the manufacturer.

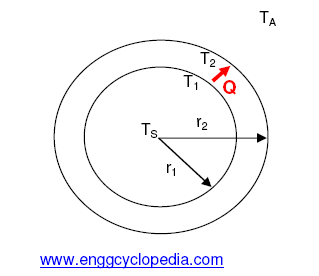

If the steam is being used only for process heating duties, no superheat is required. Superheated steam is not desirable since it results in lower heat transfer coefficients. The heat transfer coefficient of removing sensible heat is much smaller compared to the heat transfer coefficient associated with removing the latent heat from saturated steam (i.e. condensation).

Generally, it is good practice to generate the highest level of steam possible in the plant since it provides flexibility of either satisfying some high level steam process requirements or, by means of a control station letdown or back-pressure turbine, satisfying a process requirement at some lower steam level.

In a typical acid plant steam system there will be typically three different levels of steam distribution pressures; high, medium and low. High pressure steam will be generally be above 600 psig with a maximum pressure of 900 psig. Medium pressure steam will be between 150 and 250 psig. Lower pressure steam will be about 50 psig.

Line sizing for steam service

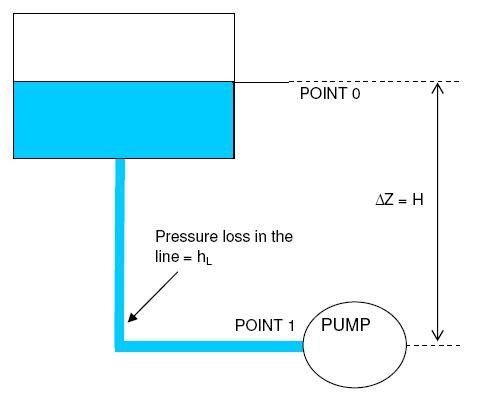

It is important that the steam generated in the boiler arrives at the end user at the desired pressure. Steam lines should be sized to ensure that the frictional losses across steam lines are not excessive. Velocities should also not be too high as this can lead to excessive noise being generated. The following criteria can be used for sizing main steam lines.

- High pressure: 2 to 3 psig/100 ft

- Medium pressure: 1 psig/100 ft

- Low pressure: 0.5 psig/100 ft

You can also use this calculator for line sizing calculations for your superheated steam lines. And if your line has condensate, use this calculator for pipes with 2 phase flow.