Positive displacement compressors are mechanical devices used to increase the pressure of a gas by reducing its volume. The major advantage of positive displacement compressors is that they deliver a constant flow of gas at a high pressure. In this post working principle of positive displacement compressors has been discussed along with its types, advantages and disadvantages.

Table of Content:

1. What is Positive Displacement Compressor?

2. Positive Displacement Compressor Working Principle

3. Positive Displacement Compressor Types

3.1. Reciprocating Compressors

3.2. Rotary Compressors

4. Advantages of Positive Displacement Compressor

5. Disadvantages of Positive Displacement Compressors

6. Positive Displacement vs Dynamic Compressor

What is Positive Displacement Compressor?

A positive displacement compressor works by trapping a fixed volume of air or gas into a fixed chamber and then reduces volume to compress it. These compressors use a mechanical device such as piston, or rotors (screw, vane or lobe) to decrease the volume and to compress the gas or air.

Positive displacement compressors can maintain relatively constant flow rate and pressure. These compressors are commonly used in applications where relatively high pressure is required such as refrigeration, air conditioning and pneumatic tools.

Positive Displacement Compressor Working Principle

The step-by-step working procedure of positive displacement compressors is discussed here.

- The compressor chamber is empty initially. The volume of compression chamber is slightly larger than the amount of gas to compressed.

- When the compressor starts, the piston or rotor inside the chamber starts moving. This reduces the volume of the compression chamber.

- As the volume of the chamber decreases, gas inside compression chamber forced to compress and results in increase of pressure.

- Once the pressure of the gas inside the chamber reaches the predetermined level, gas is discharged through a outlet discharge valve.

- After discharging high pressure gas, piston or rotor moves to its new position for suction of new volume of gas. The cycle repeats for the continuous compression of the gas.

Positive Displacement Compressor Types

Positive displacement compressors are available in two main types: reciprocating compressors and rotary compressors. The choice of compressor type depends on several factors, such as the required flow rate, pressure, and gas composition. Reciprocating compressors are typically more suited for high-pressure applications, while rotary compressors are better suited for high-flow-rate applications.

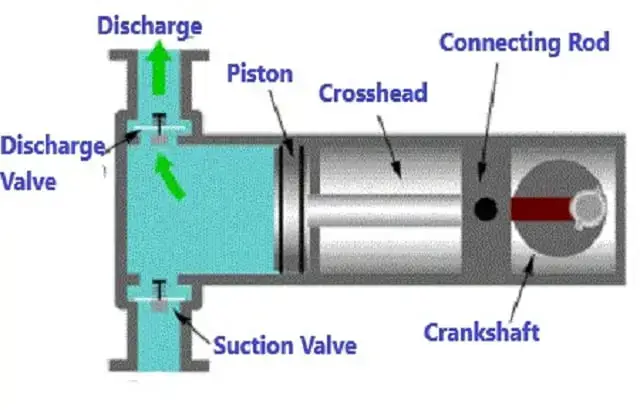

Reciprocating Compressors

Reciprocating compressors use a piston and cylinder to compress the gas. The piston moves back and forth in the cylinder, drawing in gas on the downstroke and compressing it on the upstroke. This process creates a cyclic compression of the gas in the chamber, delivering a constant flow of compressed gas to the outlet.

Reciprocating compressors are available in both single-acting and double-acting configurations. In single-acting compressors, the gas is compressed only on one side of the piston, while in double-acting compressors, the gas is compressed on both sides of the piston.

Check this post for more detailed illustration of reciprocating compressors.

Rotary Compressors

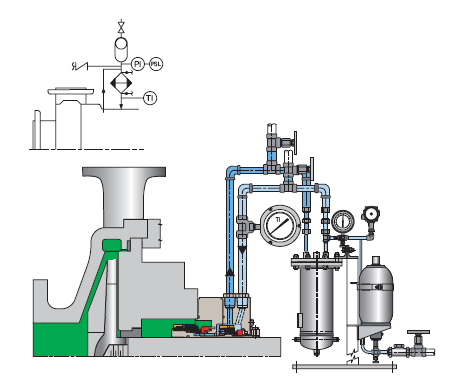

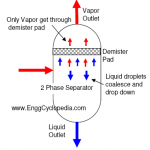

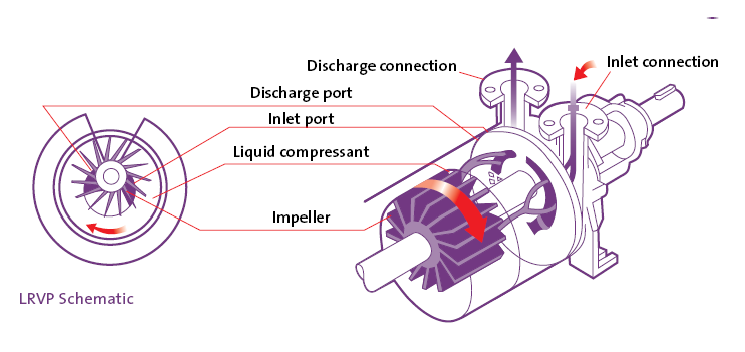

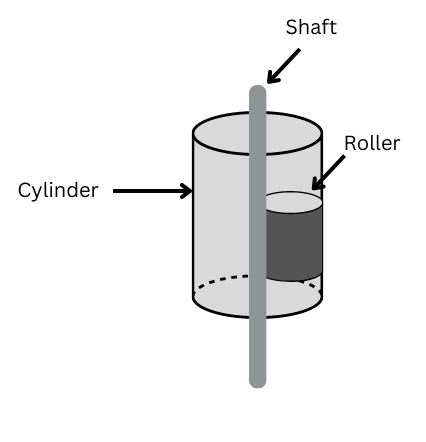

Rotary compressors use a rotating element, such as a screw, vane or lobe to compress the gas. As the element rotates, it traps gas and moves it towards the outlet, where it is compressed and discharged. Rotary compressors are available in several configurations, including helical screw compressors, scroll compressors, sliding vane compressors, liquid ring compressors and lobe compressors

Learn more about rotary compressors and check details of different types of it including liquid ring, scroll, helical screw, sliding vane and lobe in the given post.

Advantages of Positive Displacement Compressor

Positive displacement compressors offer several advantages. Some of the specific benefits of positive displacement compressors are:

- Positive displacement compressors have high mechanical efficiency because they compress gas by trapping it in a chamber and reducing its volume. This results in a high compression ratio, which reduces energy consumption.

- Positive displacement compressors can provide a constant flow rate, which makes them suitable for applications where a consistent supply of compressed gas or air is required.

- Positive displacement compressors have a simple and robust design, which makes them reliable and easy to maintain. They are less prone to failure compared to other types of compressors.

Disadvantages of Positive Displacement Compressors

Here are some of the main disadvantages of positive displacement compressors:

- They are limited in their operating range compared to dynamic compressors. They are not suitable for applications where a large volume of air or gas needs to be compressed to a relatively low pressure ratio.

- These compressors are often more expensive than dynamic compressors. This is because they require more complex mechanical components, such as pistons, rotors, or vanes, which increase manufacturing and maintenance costs.

- They require more frequent maintenance than dynamic compressors. This is because the mechanical components in positive displacement compressors are subject to more wear and tear than dynamic compressors.

- Positive displacement compressor can become less efficient at high speeds. This is because at high speeds, the mechanical components may generate more heat and friction, reducing the overall efficiency of the compressor.

- These compressors can generate more noise and vibration than dynamic compressors. This can be a disadvantage in applications where noise and vibration levels need to be kept to a minimum, such as in residential or hospital settings.

Positive Displacement vs Dynamic Compressor

| Positive Displacement Compressor | Dynamic Compressor |

|---|---|

| Positive displacement compressor work by trapping a fixed volume of air or gas and then reducing the volume to compress it. | Dynamic compressors, use high-speed rotating impellers or blades to accelerate and compress the air or gas. |

| This type of compressor is characterized by a constant flow rate, and the pressure is determined by the resistance of the discharge system. | This type of compressor is characterized by a varying flow rate and a pressure that is determined by the speed and impeller design. |

| Positive displacement compressors can maintain a high level of efficiency over a wide range of operating conditions and are often used in applications where a high-pressure ratio is required. | Dynamic compressors are often used in applications where a large volume of air or gas needs to be compressed to a relatively low pressure ratio. |