Pipeline pig traps, also known as pigging traps or pig launchers and receivers, are components used in pipeline systems to launch and receive pipeline inspection gauges or cleaning devices called pigs. These pigs are cylindrical tools that are inserted into a pipeline to perform various functions such as cleaning, inspecting, and maintaining the pipeline.

Table of Content:

1. Pipe pig traps

1.1. Pig launchers

1.2. Pig receivers

2. Structure of pig receiver / launcher

3. Important details and dimensions for design of a pipeline pig trap

Pipe pig traps

Pig launchers

A pig launcher is a vessel used to launch a pig into a pipeline.The size and shape of a pig launcher will vary depending on the size and type of pig that will be launched.

Pig launchers typically have the following features:

- A closure mechanism to prevent the pig from escaping before it is launched.

- A pressure relief valve to prevent the buildup of pressure inside the launcher.

- A drain valve to allow the removal of any fluids that may be present in the launcher.

- A nozzle to connect the launcher to the pipeline.

After being launched into the pipeline, the pig tool is pushed through the pipeline by a driving fluid. The pipeline is cleaned along the way by brushing action from the pig.

Pig receivers

A pig receiver is a vessel used to receive a pig after it has traveled through a pipeline. The size and shape of a pig receiver will vary depending on the size and type of pig that will be received.

Pig receivers typically have the following features:

- A closure mechanism to prevent the pig from escaping after it has been received.

- A pressure relief valve to prevent the buildup of pressure inside the receiver.

- A drain valve to allow the removal of any fluids that may be present in the receiver.

- A nozzle to connect the receiver to the pipeline.

Pig traps can be of horizontal, vertical or inclined type. For ease of operation, horizontal pig traps are preferred. When space constraints become critical, vertical or inclined pig traps are installed instead of horizontal.

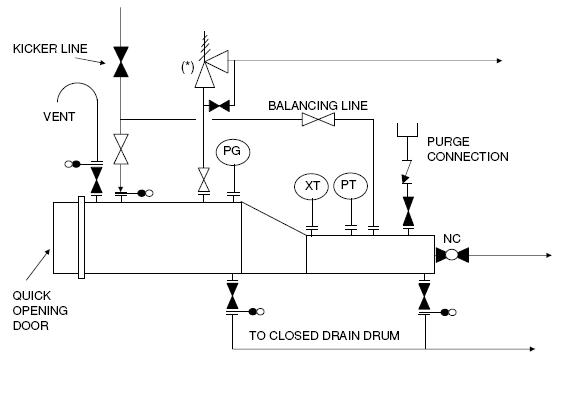

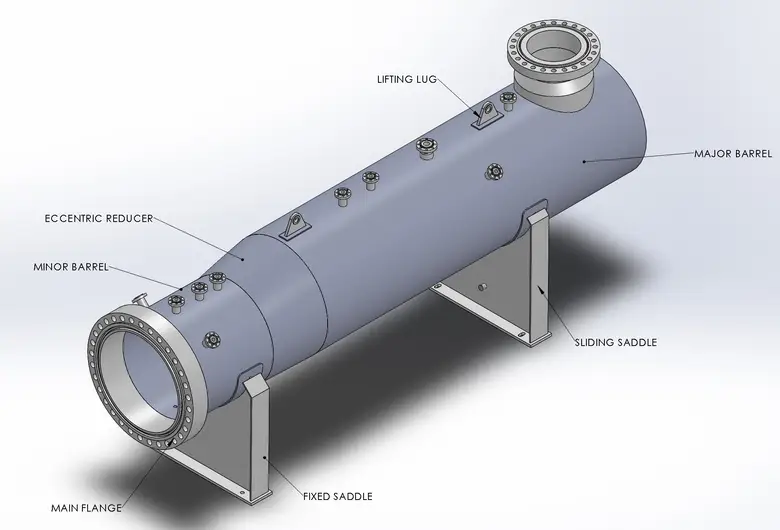

The schematic shown here is for a horizontal pig launcher. A horizontal pig receiver would be almost identical to this schematic, except for the position and size of certain nozzles such as drain, kicker line and PSV nozzle.

Structure of pig receiver / launcher

For any pig trap, be it horizontal, vertical or inclined pig launcher or receiver, basic structure is similar and consists of -

Major barrel

The major barrel is the larger of the two barrels that make up the pig trap. It is typically made of steel and is designed to withstand the pressure of the pipeline. The major barrel is larger than the pipeline size to allow for the pig to pass through.

Minor barrel

The minor barrel is the smaller of the two barrels that make up the pig trap. It is typically made of the same material as the pipeline and is sized to match the pipeline diameter. The minor barrel is where the pig is received after it has traveled through the pipeline.

Reducer barrel

The reducer barrel connects the major barrel to the minor barrel. It is typically made of steel and is designed to reduce the pressure from the major barrel to the minor barrel.

Quick opening door

The quick opening door is located on the major barrel end of the pig trap. It is typically made of steel and is designed to allow for the quick and easy removal of the pig from the pig trap.

Full bore ball valve

The full bore ball valve is located on the minor barrel end of the pig trap. It is typically made of steel and is designed to allow for the flow of fluids in and out of the pig trap.

Nozzles

The pig trap has a number of nozzles that allow for the connection of various lines. These lines include:

- Kicker line: The kicker line is used to introduce the pig into the pipeline.

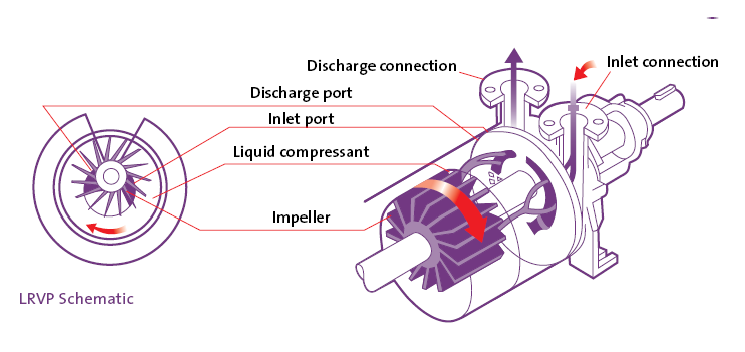

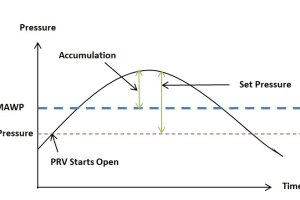

- Relieving line (PSV): The relieving line is used to relieve pressure from the pig trap in the event of an overpressure event.

- Pressure gauges: The pressure gauges are used to monitor the pressure in the major and minor barrels.

- Pig signaler: The pig signaler is used to detect the passage of the pig through the pig trap.

- Purge connection: The purge connection is used to purge the pig trap with a clean fluid before the pig is launched.

- Vent: The vent is used to vent the pig trap of any fluids or gases.

- Drains: The drains are used to drain any fluids or gases from the pig trap.

Safety interlocks

As a safety measure, the quick opening door should be mechanically interlocked with isolation valves on the kicker line and main line so that the door cannot be opened when the pig trap is still connected to these pressurized lines. This safety precaution can also be accomplished by interlocking the door with the vent or depressurizing line so that the door can be opened only when the pig trap is depressurized.

For vertical pig traps, the reducer barrel is of concentric type, so that the center lines of major and minor barrels match with each other. Vertical pig traps are always installed to have the major barrel above the minor barrel. The tentative position of the nozzle shown in the schematic, may change for vertical pig traps.

Important details and dimensions for design of a pipeline pig trap

Following certain dimensions are important for pig trap design and have to be specified in the pig trap datasheet, before sending it to the supplier.

- Major barrel size and length

- Minor barrel length and size (same as pipeline size)

- Reducer barrel length.

- Inclination type of pig trap (horizontal or vertical)

- Slope in case of horizontal pipeline pig trap

- Location of certain nozzles such as Kicker line, Relieving line, drain, vent, pig signaler.