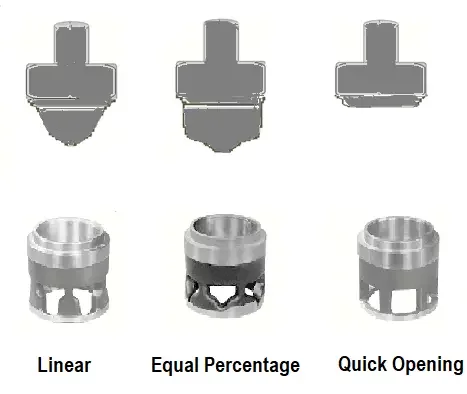

Valve trim refers to the internal parts of a valve that come in contact with the process fluid. It includes the stem, plug, disc, seating surface, etc. The shape of the valve plug determines the flow characteristics of the valve. Different valve trims can be used to achieve different flow characteristics, such as quick opening, linear, and equal percentage.

In this post, we will explore the significance of trim in valve system along with types of trims in valve systems and valve trim components.

Table of content:

1. What is a valve trim?

2. Types of trims in control valves

3. Valve trim components

What is a valve trim?

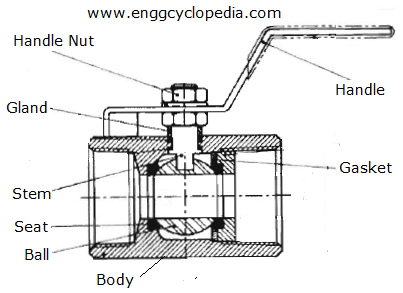

The operating parts of a valve which are normally exposed to the process fluid are referred to as 'valve trim'. Usually these parts are subject to wear and degradation and hence are replaceable. Usually parts like stem, closure member, seating surface etc. are called as valve trim. The parts such as body, bonnet, yoke etc. are not considered as trim. Trim in a control valve also influences its flow characteristics.

Following table represents a list of parts, which can be considered as trim for different types of valves.

| Type of Valves | Valve Trim |

| Angle Valves | Stem, Seat, Disc, Disc nut, back-seat bushing |

| Disc Valves | Disc, Disc nut, back-seat bushing |

| Gate Valves | Stem, Seat, wedge, back-seat bushing |

| Globe Valves | Stem, Seat, Disc, Disc nut, back-seat bushing |

| Lift type check Valves | Seat ring, Disc, Disc guide |

| Swing type check Valves | Seat ring, Disc, Disc holder, Disc holder pin, Disc nut, Disc nut pin, side plug, carrier pin |

Types of trims in control valves

The trim plays a specially important role in case of a control valve. In a control valve the trim determines 'characteristic of a valve' or in other words how the flowrate through the valve changes depending on the valve opening.

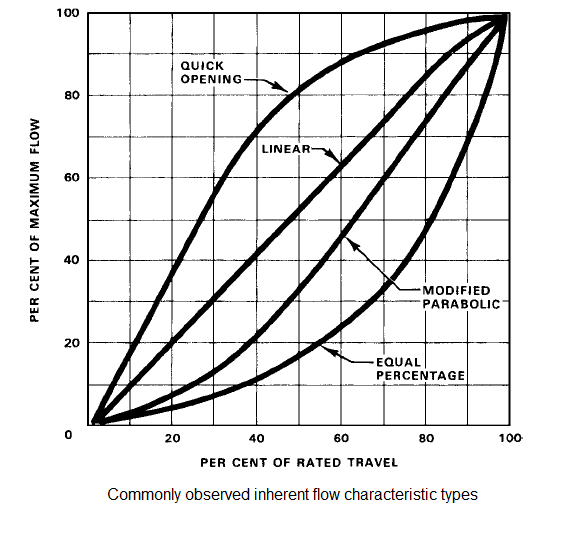

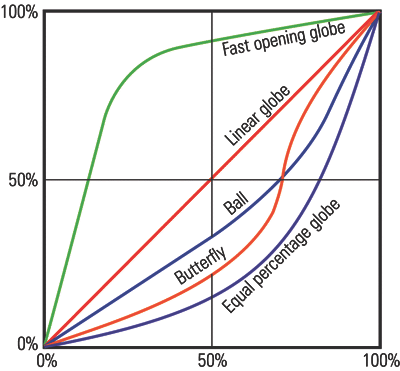

The relationship between the control valve opening (also known as ‘valve travel’) and the flow through valve is known as the flow characteristic of that valve. An inherent flow characteristic is the relation between valve opening and flow under constant pressure conditions. There are 4 main types of control valve characteristics, which are sometimes also referred to as the 'control valve trim'. Trim and characteristic terms are used interchangeably.

Following figure shows the control valve trim or characteristic for different possible valve types.

- The linear flow characteristic has a constant slope, meaning that valves of this type have constant gain through complete range of flows. These valves are often used for liquid level control and certain flow control operations requiring constant gain.

- Equal percentage valves are known by that name because whenever the valve opening is changed, the percentage change in flow is equal to percentage change in the valve opening. This means the change in flow proportional to the flow just before the incremental valve opening is performed. This can also observed in the following figure. This type of valves is commonly used for pressure control applications. They can be considered for applications where high variations in pressure drop are expected.

- Quick opening type of valves does not have a specific mathematical definition. These valves give a large increment in flow for relatively smaller valve opening, as can be observed in the following figure. These valves usually find use for on-off service applications.

- Modified parabolic valves lie somewhere between the linear valves and equal percentage valves. As can be observed in the following figure, they can be used for throttling at low flow levels and have almost linear characteristics at higher flows.

The choice of flow characteristic depends on the specific application. The following factors should be considered when choosing a flow characteristic:

- The desired range of flow rates

- The need for precise flow control

- The need for fast response

- The pressure drop across the valve

- The cost of the valve

The trim of a control valve is a critical component that must be carefully selected to meet the specific needs of the application.

Valve trim components

Valve trim components refer to the internal parts of a valve that are responsible for controlling the flow of fluid through the valve. These components work together to regulate the flow rate, pressure, and direction of the fluid passing through the valve. Some of the essential valve trim components are discussed here.

Disc

The disc is the part of the valve that closes off the flow of the medium and controls the flow of fluid. The shape of the disc is important because it determines the flow characteristics of the valve. For example, a disc with a sharp edge will create a more turbulent flow than a disc with a rounded edge.

It is typically made from a hard material, such as cast iron or stainless steel, to resist wear and corrosion. The disc is shaped to create a seal against the valve seat when the valve is closed. The disc is held in place by a spring or other mechanism. The disc can be replaced if it becomes worn or damaged.

Seat

The seat is the part of the valve that the disc seals against. A valve seat is a part of a valve that does not bear pressure. Valves can have one or more seats. Globe and swing check valves have one seat that seals against the disc to stop the flow. Gate valves have two seating surfaces that come into contact with the seats. Ball and plug valves have several seats, depending on the number of ports.

Valve seats can be integral, renewable, or replaceable rings. Small valves have screwed-in, swaged-in, or welded seats. Large valves may have any of the seats used in small valves, or they may have integrally cast or forged seats along the valve body.

Integral seats are cast or forged as part of the valve body. Renewable seats are made of a replaceable material, such as a soft metal or a ceramic. Replaceable rings are made of a hard material, such as a metal or a ceramic, and are installed in the valve seat.

Back seat

The back seat refers to a component of the valve that is not designed to withstand pressure. It is used to prevent leaks if the main seat becomes damaged. The back seat can be made in a variety of materials, including metal, plastic, and rubber. The material of the back seat is important because it must be compatible with the flow medium.

It is made up of a shoulder on the stem. When the stem is in a fully open position, it forms a seal that prevents leakage from the valve shell to the packing chamber and the environment. The back seat is especially important in valves that are used to control the flow of hazardous materials.

Stem

The stem is the part of the valve that the disc is attached to. It is typically made of metal and is threaded to allow the disc to be moved in and out of the valve body.

The stem serves as the link between the actuator, valve handwheel, and the disc, plug, or ball in a valve. It is responsible for the movement required to open and close the valve. Consequently, the valve's opening and closing action is achieved through the motion of the stem.

Gate or globe valves, for instance, require linear motion of the disc to open or close the valve, while plug, ball, and butterfly valves rely on the rotation of the valve disc.

Gland

The gland is a packing material that is used to seal the stem in the valve body. It is typically made of a soft material, such as PTFE, to prevent the stem from corroding.

FAQs

1. What is the purpose of valve trim?

It is designed to control and manipulate the flow of fluids through the valve. It is responsible for maintaining proper sealing, controlling pressure, and regulating the flow rate.

2. What are the different types of valve trim based on material?

Various types of materials are used to suit different applications. Common types include:

- Soft Trim: Soft materials like rubber or elastomers are used in the trim to provide excellent sealing properties, making it suitable for low-pressure applications.

- Metal Trim: Metal components, such as stainless steel or tungsten carbide, are used for high-pressure and high-temperature applications.

- Cage Trim: These valves use a cage-like structure to support the valve plug, which is ideal for applications requiring precise control and high pressure differentials.

3. What factors should be considered when selecting valve trim?

When selecting valve trim, factors like the fluid type, temperature, pressure, flow rate, and the specific application's requirements should be taken into account. It is essential to choose trim materials and designs that can withstand the conditions and provide optimal performance.

4. How does valve trim affect valve performance?

Valve trim plays a significant role in determining the valve's performance. The choice of trim can influence factors such as flow capacity, pressure drop, and the ability to handle abrasive or corrosive fluids. Proper trim selection is crucial to achieve the desired control and longevity of the valve.

5. What is the difference between a control valve trim and a shut-off valve trim?

Control valve trim is designed for applications where precise flow control is necessary, while shut-off valve trim is designed for isolation and complete sealing. Control valve trim is optimized for modulating flow, while shut-off valve trim focuses on tight sealing when fully closed.

6. Can valve trim be replaced or upgraded?

Yes, it can often be replaced or upgraded without replacing the entire valve. This can be a cost-effective way to adapt valves to changing operating conditions or extend their lifespan.

7. What maintenance is required for valve trim?

Regular maintenance may involve inspecting, cleaning, and replacing worn or damaged trim components. Proper maintenance helps ensure the valve continues to perform optimally.

8. Where can I find information on the suitable valve trim for my application?

To select the right trim, consult valve manufacturers' catalogs, engineering specifications, or seek guidance from experienced professionals or knowledgeable engineers.