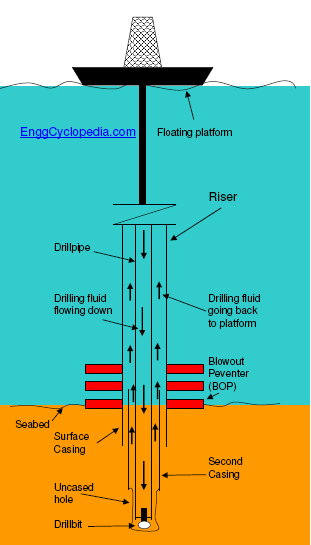

Gas lift systems enable the efficient extraction of drilling fluid such as crude oil or gas from oil wells. Gas lift is an artificial lit system by which gas is injected into produced well casing to help lift liquids up to the surface through the production tubing. Gas lift valves are most important part of gas lift systems and helps in lifting drilling fluid to intended zone. Explore use of gas lift valves in gas lift systems in this post.

Table of content:

1. What are gas lift valves?

2. Types of gas lift valve

What are gas lift valves?

These valves are designed to control the injection of gas into production tubing. This injection of gas ensures that the drilling fluid reaches the desired zone within the well.

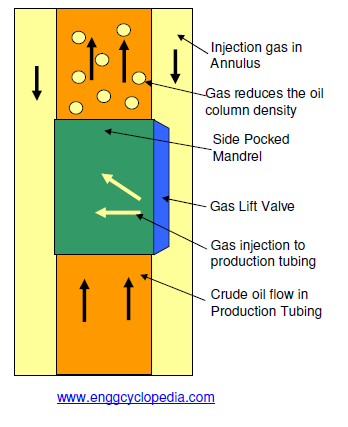

Gas lift valve acts as a gatekeepers and allows lift gas to flow from the annulus surrounding production tubing to the tubing itself. This controlled flow of gas helps in maintaining lift efficiency. These valves open and close at specific pressures to regulate the injection of gas. This ensures that the lift gas reaches the intended zone within the well.

Gas lift valve is strategically positioned within the gas lift mandrel. Due to that the gas lift valves establish a connection between the lift gas supply in the tubing annulus and the production tubing. The mandrel acts as a conduit. This allows the lift gas to flow from the annulus into the tubing, where it can aerate the fluid and reduce hydrostatic pressure, enabling the oil or gas to flow to the surface.

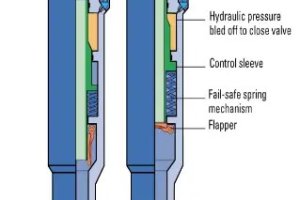

The operation of gas lift valve is governed by preset opening and closing pressures. These pressures are carefully determined based on the specific requirements of the well and desired lift gas flow rate.

The gas lift valve opens when the preset opening pressure is reached and allows the lift gas to enter the production tubing. Conversely, the valve closes when the preset closing pressure is reached preventing further flow of gas. This mechanism ensures that the lift gas injection occurs at the right time and in the right amount.

Gas Lift for Oil Wells

Gas lift is an artificial-lift method for enhancing crude oil recovery from a reservoir. The gas injected in the oil column reduces the effective density of oil in production tubing, thus reducing the hydrostatic pressure of the oil column in the well. The reduced pressure of the oil column above the reservoir allows the reservoir fluids to enter the oil well bore at a higher flow rate. Gas lift can be either continuous or intermittent, depending on the productivity of the concerned wells. Explore details about gas lift system for oil wells in the given post.

Types of gas lift valve

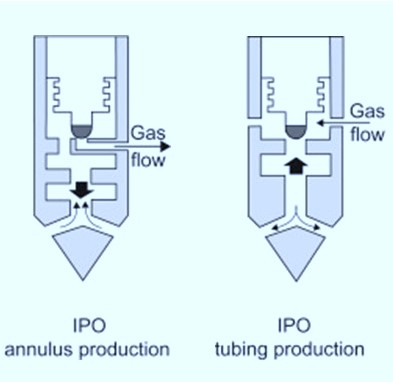

Injection Pressure Operating (IPO) valves

IPO valves are one of the most common types of gas lift valves used in gas lift systems. These valves consist of a nitrogen-charged dome, bellows, stem, and seat. In this type of valve the bellows contract when the pressure outside the bellows exceeds the pressure inside the nitrogen-charged dome. This pulls the ball away from the seat. This action allows the injection of gas to flow into the production tubing resulting in fluid aeration and improved production efficiency.

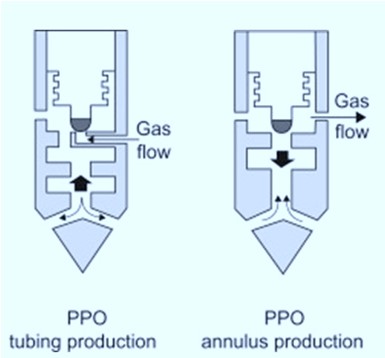

Production Pressure Operated (PPO) valves

PPO valves are another type of gas lift valve used in gas lift systems. These valves use high-quality Inconel springs as the closing force instead of the nitrogen charged dome. The Inconel springs is resistant to temperature changes which makes them unaffected by wellbore conditions.

These valves are particularly used in common-annulus dual installations. In such setups, multiple wells share a common annulus. This requires precise control of gas lift operations. PPO valves, with their robust design and temperature independence, provide reliable and efficient gas lift control in these complex configurations.