A subsurface safety valve is essentially a shutdown valve installed at the upper wellbore for emergency shutdown to protect the production tubings and wellhead in case of overpressure. Purpose of a subsurface safety valve (SSSV) is to avoid the ultimate disaster which can result in release of reservoir fluids to the surroundings. This makes SSSV a very important component of a well completion.

To protect the surface facilities in case of emergency, the wellbore is isolated from surface facilities using a subsurface safety valve (SSSV). Hence such a safety valve needs to be fail safe in order to isolate well bore in any kind of system failure or damage to surface production, control and safety facilities.

Table of content:

1. Functions of SSSV

2. Working mechanism of Subsurface Safety Valves

Functions of SSSV

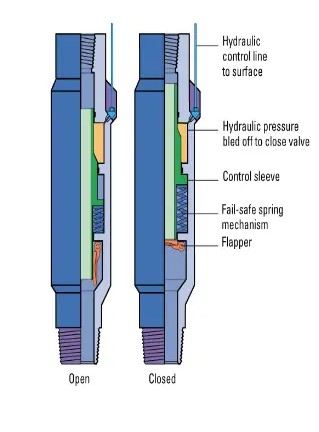

A subsurface safety valve is typically a uni-directional flapper valve, directed in such a way that the flappers open downwards when pressure is applied from an upward direction. The flapper can only open in the downward direction. This means that when pressure from the reservoir pushes fluids upward the flappers open and allows the flow.

This unique design of flappers makes the subsurface safety valve fail safe. So even if high pressure is applied by the well fluids from a downward direction ((such as during a blowout or well control issue), a safety valve can remain closed. This ensures that the wellbore is isolated and prevents uncontrolled release of fluids.

To open the valve, hydraulic signal is sent from the surface well control panel. This hydraulic pressure is responsible for keeping the flappers of SSSV open.

Loss of hydraulic pressure or a decrease below a certain threshold results in closing of the subsurface safety valve. If the hydraulic pressure is compromised due to system failure or damage to the surface facilities, the valve automatically closes, isolating the wellbore. Thus wellbore can be isolated in case of system failure or damage to the surface facilities.

Working mechanism of Subsurface Safety Valves

The valve contains various components such as flapper, sleeve, control line and a large spring. The step by step working procedure of SSSV is explained here.

- SSSV activates when the hydraulic pressure is applied through the control line.

- This exerts force on a sleeve and causes it to move downwars.

- As the sleeve moves downward, it compresses a large spring in the valve.

- The compression of spring pushes the flapper downward. This opens the valve and allows drilling fluid through the wellbore.

- Loss of hydraulic pressure results in loss of pressure in control line. Due to that spring's stored energy gets released. This causes the sleeve to move back upward. Flapper returns to its original position and closes the valve.

This fail safe mechanism is important for protecting wellbore in critical conditions such as system failures by preventing any uncontrolled release of drilling fluid. Spring's energy ensures that the valve remain closed and isolates the wellbore.