Every bearing has a pre-calculated service life. but for various reasons, not every bearing achieves it. Important stages which have a major impact on a bearing service life can be recognised during the bearing’s lifecycle. These stages are mounting, lubrication, alignment, basic condition monitoring and dismounting.

The stages in a bearing life cycle are extremely important for achieving the maximum service life of the bearing. By applying the right maintenance practices and using the correct tools, you can considerably extend your bearing’s service life and increase plant productivity and efficiency.

|

Tool Name |

Description |

Application |

|

| Jaw pullers can accommodate a wide range of bearing types and sizes. With self-locking arms, the pulling width is easily adjusted and automatically fixed without the need of arm locking bolts. It is equipped with a hexagonal head allowing it to be easily rotated during dismounting. |

Internal and external pulling of bearings and other components, with equal strength.

|

||

|

|

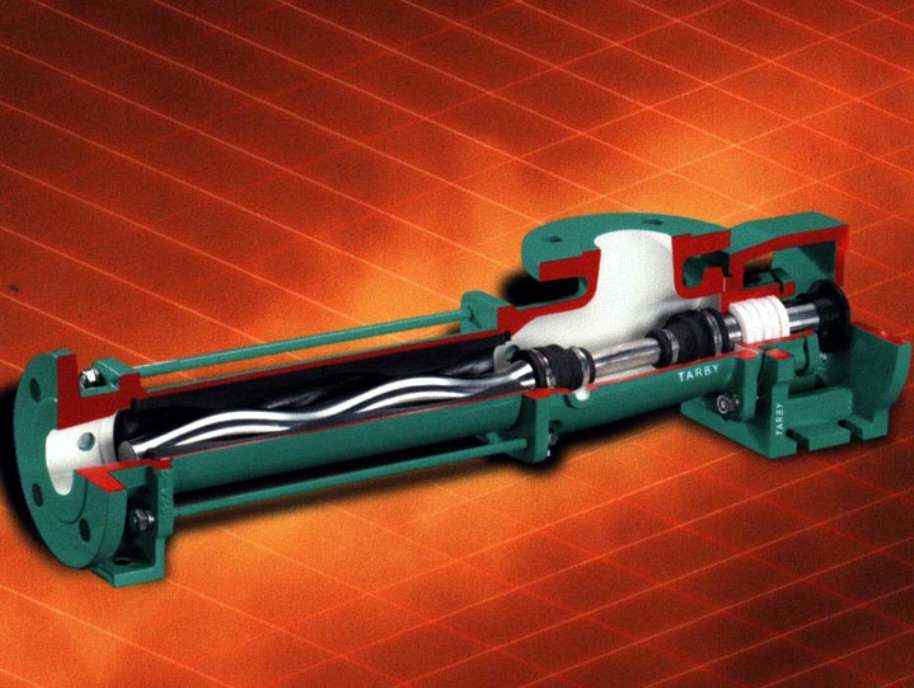

Suitable for dismounting spherical roller bearings, and other components such as pulleys and flywheels has a maximum withdrawal force of 100 kN and a long stroke of 80 mm, which facilitates most dismounting jobs in just one operation. |

Bearing dismounting jobs. |

|

| mounting force to the bearing ring with the interference fit, minimising the risk of damaging the bearing’s raceways or rolling elements, Facilitates correct mounting on shaft, housing and blind applications

|

Bearing mounting jobs. |

||

| Spanner and sockets are used to tighten and loosen many types and sizes of bearing lock nuts, for bearings mounted directly on a shaft or on sleeves. |

Tightening and loosing of bearing nut.

|

||

| It helps avoid shaft and nut damage The impact force applied effectively to the nut which is suitable for a wide selection of lock nuts, special wide impact face to be used in combination with a hammer |

Installation procedures of bearing nuts. |

||

|

Hydraulic nut and pump |

Hydraulic Nut facilitates easy and quick application of the high drive-up forces required for mounting and dismounting bearings. Oil is pumped into the nut and the piston is pushed out with a force, which is sufficient to free the sleeve. |

Bearing mounting and dismounting jobs |

|

| Induction heaters are the modern, efficient and safe way to heat bearings. In operation, they are generally faster, cleaner, more controllable, and easier to use than other heating methods such as oil bath, open flame and ovens . |

Used for efficiently heating bearings and work pieces. |

||

| Three leg puller used in maintenance process of bearing. |

Used to dismantle bearings form equipment shafts came with different sizes according to the bearing size. |

||