Steam hammering is the sound that is heard as a pinging, rattling, or banging in a steam system under conditions of Start-up, shutdown, changing loads or even in few cases, steady state full load operation.

Steam hammering, also known as steam hammer blow, occurs during specific operations involving steam injection. It arises when steam encounters a high-pressure zone or encounters flow restrictions, resulting in rapid condensation and the release of a powerful shockwave within the system.

The consequences of steam hammering are equipment failures, production interruptions, and safety hazards. In this post, we will study the causes and occurrences of steam hammering, along with its associated risks, and strategies to mitigate this phenomenon.

Table of content:

1. Steam hammering in pipes

2. What causes steam hammering?

3. Effects of steam hammering

4. How to prevent steam hammering?

Steam hammering in pipes

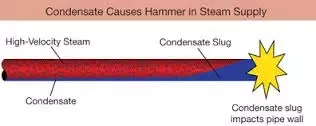

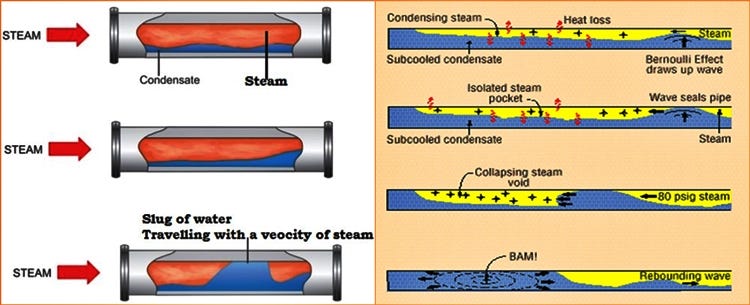

Steam hammer is a phenomenon that occurs when steam condenses rapidly in a fluid handling system. Steam hammering occurs in the pipeline while there is a presence of condensate in the line. This is because of sudden drop in pressure of steam as it comes in contact of condensate. This can cause a number of problems, including:

- Banging noises

- Pressure spikes

- Vibration

- Damage to equipment

- Safety hazards

What causes of steam hammering?

There are a number of factors that can contribute to steam hammering, including:

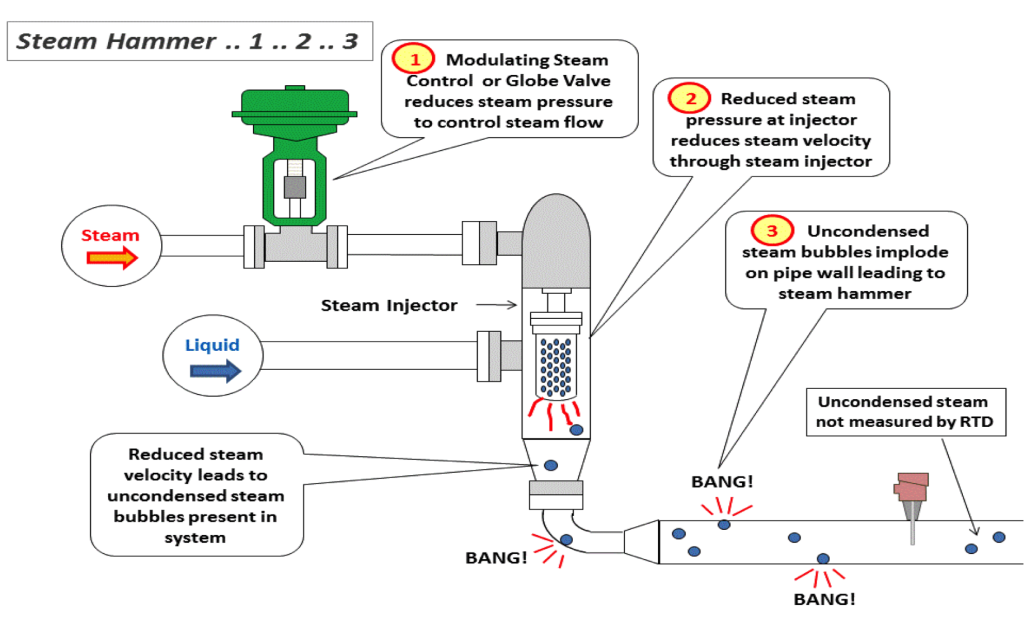

Steam hammer can occur in a variety of situations, but it is most common when steam is directly injected into a tank or pipe containing a liquid. This is because the steam can condense rapidly on the cold surface of the liquid, creating a low-pressure zone. The liquid then rushes in to fill the low-pressure zone, creating a pressure spike.

Steam hammering can occur due to poor heating of steam network before the steam enters into the system. Piping network remains cool and as soon as the hot steam enters, condensation takes place and water gets accumulated in the lines forming a Slug. As the steam flow increases, steam carries the water with it and lot of momentum is created and it hammers the line loops with tremendous forces creating a lot of stress. Steam hammers can blow flange joints and can damage piping supports and even piping itself.

Poor condensate drainage in pipeline leads to this steam hammering. Where Air-filled traps are used to prevent condensate from backing up into the steam piping system. However, over time, the air in these traps can be absorbed by the water, which can lead to steam hammering. This can be cured by shutting off the supply, opening taps at the highest and lowest locations to drain the system and then closing the taps and re-opening the supply.

Effects of steam hammering

Steam hammer is a phenomenon that occurs when steam condenses rapidly in a fluid handling system. This can cause a number of problems, which are illustrated here.

- Cracking of steam traps and pressure gauges: Steam traps and pressure gauges are designed to withstand the pressure of steam. However, if steam hammer occurs, the sudden pressure spikes can cause these devices to crack.

- Break pipe welds and even rupture piping systems: Steam hammer can cause the welds in piping systems to break. In severe cases, steam hammer can even rupture piping systems.

- Bend internal system mechanism: Steam hammer can cause the internal mechanisms of systems to bend. This can lead to damage to valves, pumps, and other equipment.

- Causes valve failure: Steam hammer can cause valves to fail. This can lead to leaks and other problems.

- Cause heat exchanger equipment tube failures: Steam hammer can cause the tubes in heat exchanger equipment to fail. This can lead to leaks and other problems.

- Failure of pipe supports: Steam hammer can cause the supports that hold up pipes to fail. This can lead to pipes falling and causing damage.

How to prevent steam hammering?

Steam hammering condition exists in a steam system where condensate coexists with generated steam or flash steam. Typical examples include heat exchangers, tracer lines, steam mains, condensate return lines and sometimes, pump discharge lines.

A common example of steam hammer occurs during start-up or energizing of a steam system. If the steam line is energized too quickly without proper warm up time and condensate created during the start-up is not properly removed; steam hammer will be the result.

There are few design or system changes that can be implemented to prevent or eliminate steam hammering:

- Ensure correct steam and condensate design.

- Have documented SOP’s (standard operation procedures) for steam system start-ups and shut downs.

- Proper training for plant personnel.

- Have installation standards for steam components.

- Correct condensate connections of branch lines to the main condensate header and entry only from the top of the header.

- Use steam traps that are properly sized and appropriate for the application.

- Use warm-up vales as steam line isolation valves larger than 2 inches. Do not “crack open” large steam isolation valves.

- Check or repair the pipe insulation. It saves energy and reduces accumulation of condensate in the piping system

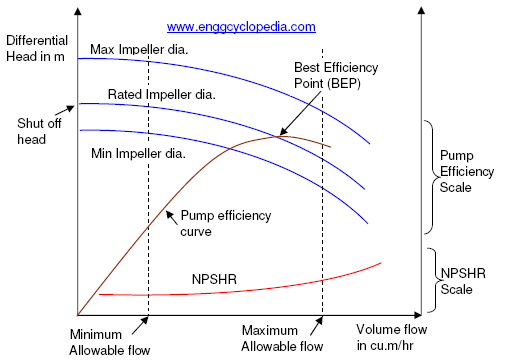

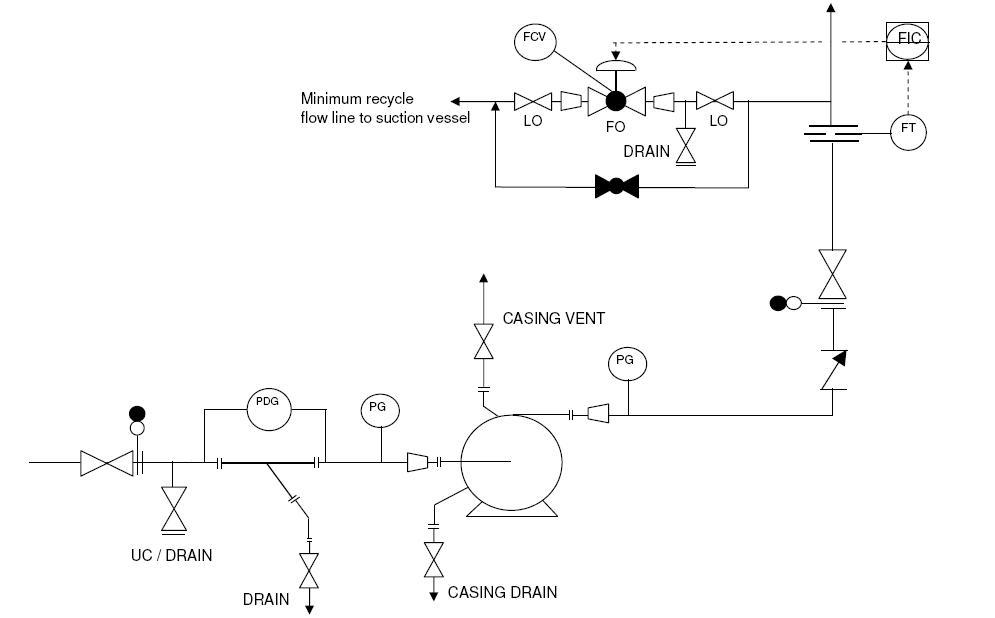

- Make sure that the condensate pump is in good working condition

There are more number of things that can be done to prevent steam hammer, including:

- Insulating the fluid lines: This will help to prevent the steam from condensing rapidly.

- Using a surge arrestor: A surge arrestor is a device that can help to dampen pressure spikes.

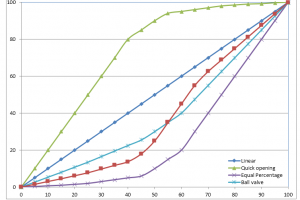

- Gradually opening and closing valves: This will help to prevent sudden changes in steam flow.

- Avoiding rapid changes in steam flow: This will help to prevent steam from condensing rapidly.

- Using a sparger to distribute steam evenly: This will help to prevent steam from condensing in one area and causing pressure spikes.

- Monitoring and regulating the temperature of the liquid: This will help to prevent steam from condensing rapidly.

By taking these steps, you can help to prevent steam hammer and protect your equipment and personnel.

In addition to the problems mentioned above, steam hammer can also cause problems with temperature control. When steam is directly injected into a tank containing a liquid, the steam can condense unevenly, causing temperature variations. This can damage temperature-sensitive materials or processes that require precise temperature control.

To minimize temperature variations, it is important to use a sparger that creates a uniform distribution of steam throughout the tank. You should also consider using a temperature controller to monitor and regulate the temperature of the liquid.

By taking these steps, you can help to prevent steam hammer and ensure that your fluid handling system operates safely and efficiently.