Pressure Safety Valves (PSV) or Pressure Relief Valves are important instruments in the process / manufacturing industry to protect enclosed equipment or vessels from over-pressure scenarios. A pressure safety valve (PSV) protects the concerned equipment or vessel in case of pressure build up, by opening up and releasing the fluid service to lower the internal pressure. Proper PSV testing is crucial to ensure proper functioning of PSV in overpressure situation. This post discusses need for Pressure safety valve testing along with the types of it.

Table of content:

1. PSV design, procurement & installation

2. PSV Testing

3. Types of PSV Testing

3.1. In situ or online PSV testing

3.2. Bench testing

PSV design, procurement & installation

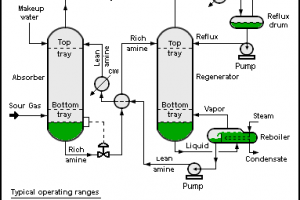

Safety valves are designed by analyzing the concerned equipment, related fluid service, then simulating the overpressure scenario to finally perform pressure safety valve sizing calculations.

The design of safety valves start with analysis of equipment that it will protect. It covers following points.

- Type of equipment

- Size of equipment

- Operating pressure of equipment

- Type of fluid in the equipment

- Define overpressure scenario for particular process and equipment. Based on overpressure scenario estimate set point pressure.

Based on the sizing calculations, PSV datasheet is prepared and a safety valve is procured and then installed on the equipment to be protected. Datasheet contains following information.

- The setpoint pressure of the safety valve

- The size of the safety valve

- The type of fluid that the safety valve is designed to handle

- The materials that the safety valve is made of

PSV Testing

But, before the plant is operational and one can rely on the PSV to protect the equipment from overpressure, it is important that the PSV has been tested. safety valve testing is an essential procedure to ensure proper working of PSV. By doing pressure safety valve testing engineers are able to identify issues in the working of safety valves.

Over time wear and tear, corrosion or debris accumulation can degrade the performance of PSVs. If the safety valve fails to open in an overpressure situation, hazards can occur. Testing of the safety valve allows verification of the proper functioning of the safety valve in an overpressure situation and prevents such catastrophic failures.

Following factors are closely examined during a PSV test -

- The valve should open up at set pressure of the PSV.

- The discharge fluid rate should be achieved corresponding to PSV datasheet for overpressure scenario.

- When the pressure is lowered, the valve seat should come down and close tightly.

Types of PSV Testing

There are two ways for testing a PSV.

In situ or online PSV testing

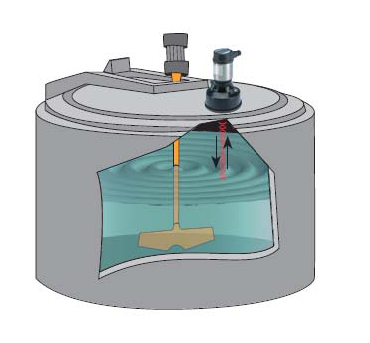

In situ or online PSV testing is done when the valve is installed in a plant. Online testing is more cost effective as it can allow the plant operations to go on while testing is being done.

But on the other hand, per valve PSV testing costs are much higher, as it requires specialized equipment and trained personnel.

Bench testing

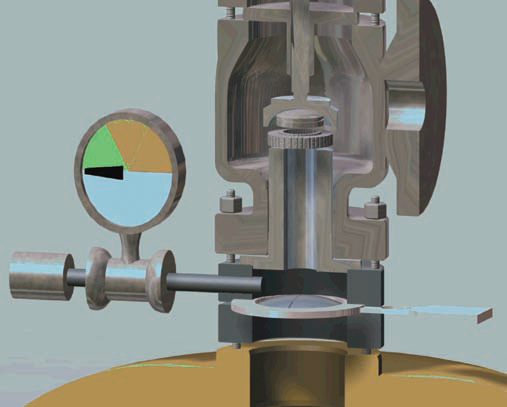

Bench testing for PSVs requires removing the relieving devices from their installation and then carrying out a full functional test to check how the valve behaves in case of over pressure scenario.

Correspondingly, PSV testing cost on per valve basis turns out to be quite low in the bench testing case. But it can result in loss of production involving equipment shutdown and removal of valve for testing purpose.