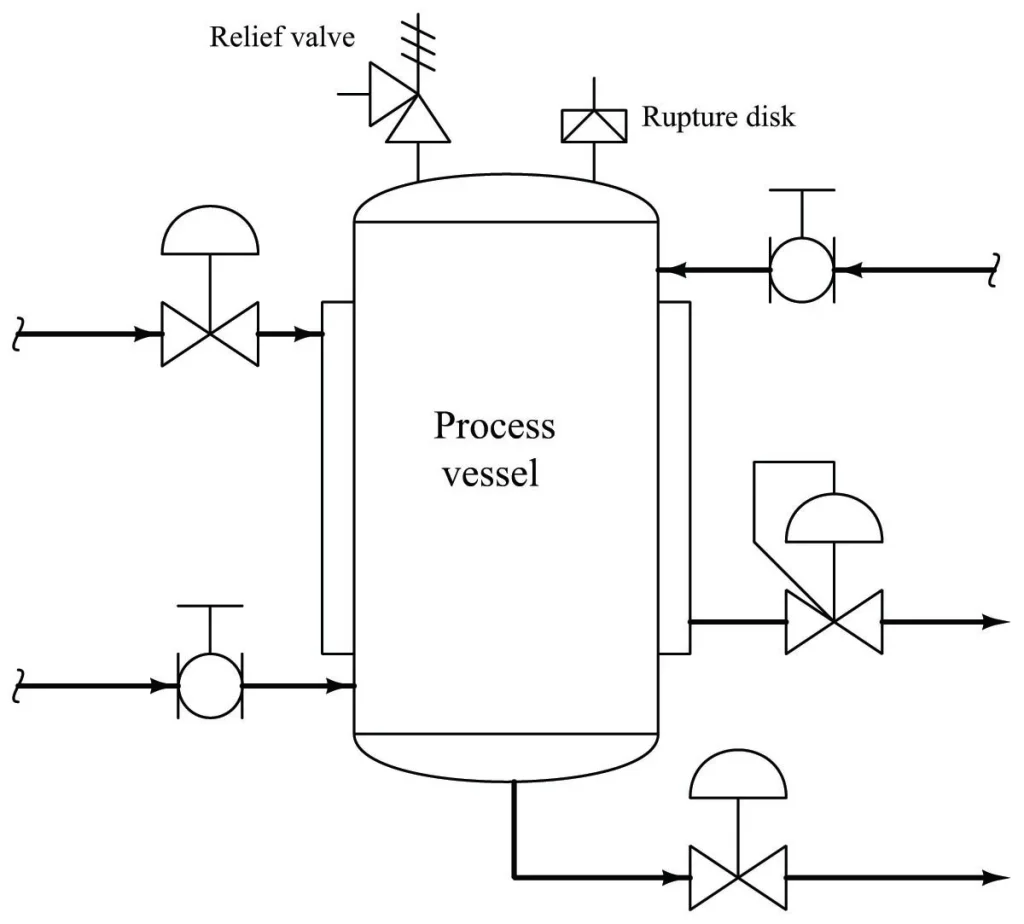

Pressure Safety Valves (PSV) or Pressure Relief Valves are important instruments in the process/manufacturing industry to protect enclosed equipment or vessels from over-pressure scenarios. A pressure safety valve (PSV) protects the concerned equipment or vessel in case of pressure build-up, by opening up and releasing the fluid service to lower the internal pressure. Safety valves are designed by analyzing the concerned equipment, and related fluid service, then simulating the overpressure scenario to finally perform pressure safety valve sizing calculations. This post discusses various overpressure scenarios and pressure relief valve sizing calculations for some of those cases.

Table of content:

Pressure relief valves

Overpressure scenarios for pressure relief valve sizing

Relief valve sizing for different cases

Pressure relief valves

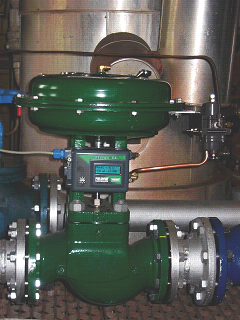

A pressure relief valve is a safety device designed to protect equipment and systems from overpressure conditions that could result in damage or failure. The valve is typically installed in a pipeline or vessel and is set to open at a predetermined pressure, allowing excess pressure to be released and reducing the risk of damage or catastrophic failure.

The pressure relief valve works by using a spring-loaded mechanism that is designed to open once a certain pressure threshold is reached. This allows fluid or gas to be vented out of the system, reducing the pressure and preventing further damage.

Pressure relief valves are commonly used in a variety of applications, including steam boilers, pressure vessels, pipelines, and hydraulic systems. They are a critical component in ensuring the safe operation of these systems and are required by many industry standards and regulations.

It is important to ensure that pressure relief valves are properly installed, tested, and maintained to ensure their effectiveness in protecting against overpressure conditions. Regular inspections and testing are necessary to ensure that the valve is functioning properly and is set to the correct pressure.

Overpressure scenarios for pressure relief valve sizing

Combination of a variety of causes may lead to over pressure in these equipments which may exceed the maximum allowable working pressure (MAWP) value in separator vessels, storage tanks, heat exchangers, columns and certain piping segments. That's why it is important to discuss various scenarios that can lead to overpressure in equipment and the need for pressure relief valves (PRV) to protect against such situations. Some common causes of over pressure which are considered for pressure relief valve sizing are discussed below.

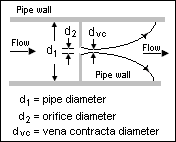

- In subcritical gas flow, the velocity of the gas is lower than the speed of sound. The pressure relief valve is designed to open and release excess gas when the pressure in the system exceeds its set pressure, reducing the pressure in the system.

- Critical gas flow occurs when gas is at pressures and temperatures above their critical points, and it can lead to overpressure situations that require pressure relief valves to prevent accidents.

- In blocked liquid discharge scenario a valve on the outlet of equipment is closed, resulting in the accumulation of fluid and pressure build-up. The pressure can reach the design pressure of upstream pumps or compressors combined with the height of the liquid column upstream.

- Inadvertent opening of high-pressure valves upstream can cause overpressure in the protected equipment, which may result in equipment failure. The excess flow resulting from valve opening should be relieved to prevent equipment damage using pressure relief valve.

- Sometimes failure of utilities such as electricity, instrument air, steam, fuel, cooling water, etc. can lead to overpressure in related equipment and should be considered when analyzing the possibility of overpressure in equipment.

- If one source of utility fails but another independent source is still available in parallel to bear complete or part of the extra load caused by partial utility failure, the partially available utility can be considered to evaluate possible over pressure in the protected equipment. This is called partial failure scenario.

- The failure of tubes in a heat exchanger can cause overpressure on the low-pressure side due to fluid flow from high pressure to low pressure, and the need for a relief valve should be evaluated.

- Equipments that are exposed to a plant fire may be at risk of overpressure due to the expansion or vaporization of fluids.

Check this post to study more about various overpressure scenarios which are considered for pressure relief valve sizing.

Relief valve sizing for different cases

Here are some demonstrated examples of relief valve sizing calculations for different types of overpressure scenarios.

Relief valve sizing for steam service

When a steam discharge line is blocked, the steam pressure in the line can increase rapidly, leading to an overpressure scenario.

Problem statement:

Protected equipment : Reboiler

Relief service : Steam

Reason for relief : Blocked steam discharge

Relieving Rate : 10,000 kg/hr

Gas Density : 2.5 kg/m3

Ratio of specific heats for the gas (CP/CV) : 1.3

Compressibility factor of gas = 1.1

Molecular weight of gas = 18 gm/mole

Relieving temperature = 2500C

Set pressure : 5.0 barg

Accumulation : 10%

Back pressure at relief valve discharge : 0.5 barg

Type of relief valve : Conventional pressure relief valve

This is the sample problem for design of pressure relief valve for steam service. Click the button to check relief valve sizing for steam service.

Relief valve sizing calculations for subcritical gas service

In the subcritical gas flow case, the gas flow rate is below the critical flow rate, which means the velocity of the gas is lower than the speed of sound.

Problem Statement: Design a pressure relief valve for the following service.

Protected equipment : Separator vessel

Relief service : Fuel Gas

Reason for relief : Blocked gas discharge

Relieving Rate : 10,000 kg/hr

Gas Density : 4.1 kg/m3

Ratio of specific heats for the gas (CP/CV) : 1.55

Compressibility factor of gas = 0.95

Molecular weight of gas = 20 gm/mole

Relieving temperature = 200C

Set pressure : 4.5 barg

Accumulation : 10%

Back pressure at relief valve discharge : 2.1 barg

Type of relief valve : Balanced Bellows

Check the solution of relief valve sizing calculations for subcritical gas service.

PRV sizing for critical gas service

Critical gas flow refers to the flow of gas at pressures and temperatures above their critical points, where the gas can no longer be compressed and becomes a supercritical fluid with properties of both a gas and a liquid.

Problem Statement: Design a pressure relief valve for the following service.

Protected equipment : Separator vessel

Relief service : Fuel Gas

Reason for relief : Blocked gas discharge

Relieving Rate : 10,000 kg/hr

Gas Density : 4.1 kg/m3

Ratio of specific heats for the gas (CP/CV) : 1.35

Compressibility factor of gas = 0.95

Relieving temperature = 200C

Set pressure : 5 barg

Accumulation : 10%

Back pressure at relief valve discharge : 0.5 barg

Type of relief valve : Conventional

Click the button to check the solution for PRV sizing for critical gas service.

PRV sizing for blocked liquid discharge

Blocked liquid discharge is an overpressure scenario where a valve on the equipment outlet, such as a vessel or heat exchanger, is closed

Problem Statement: Design a pressure relief valve for the following service.

Protected equipment : Separator vessel

Relief service : Water

Reason for relief : Blocked liquid discharge

Relieving Rate : 100,000 kg/hr

Water Density : 1000 kg/m3

Water Viscosity : 0.8 cP

Set pressure : 5 barg

Accumulation : 10%

Back pressure at relief valve discharge : 0.5 barg

Type of relief valve : Conventional

Check the solution of sample problem for PRV sizing for blocked liquid discharge scenario.

PRV sizing calculator for fire around liquid filled vessel

Check Enggcyclopedia's pressure safety valve sizing calculator for fire case for a liquid filled vessel. This calculators should be used when gas resulting from boiling of the liquid is discharged through the safety relief valve.

PRV sizing calculator for fire around gas filled vessel

Check Enggcyclopedia's pressure safety valve sizing calculator for fire case for a gas filled vessel. This calculator should be used when determining the required capacity of a safety valve for a gas-filled vessel in the event of a fire. This calculation is necessary to ensure that the safety valve can handle the maximum pressure generated during a fire scenario and prevent the vessel from overpressurizing.