Heat pumps can transfer heat from a low-temperature stream to a high-temperature stream, making them an energy-efficient option for many process heating applications. In this post, we will explore the heat pump cycle for heating in process industries, including the basic components of a heat pump.

Table of content:

What is a heat pump?

Heat pump cycle

Carnot heat pump

What is a heat pump?

A heat pump is a type of heating and cooling system that can transfer heat from one place to another using refrigerant. In process industries, a heat pump can be used to heat or cool process streams, depending on the specific application.

A heat pump can be considered as a heating device when its purpose is to warm the heat sink. Conversely, it can be seen as a refrigeration or cooling device when its purpose is to cool the heat source. However, the operating principles for heating and cooling are essentially the same.

Heat pump cycle

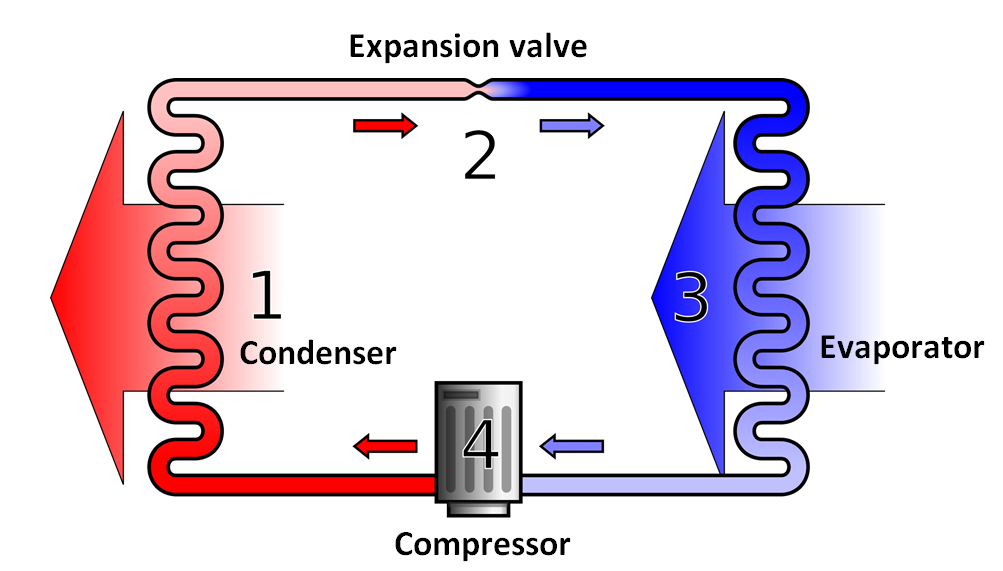

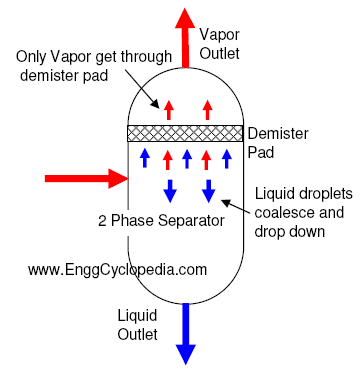

The heat pump cycle for heating involves a series of processes that enable the transfer of heat from a low-temperature stream to a high-temperature stream. The basic components of a heat pump include a compressor, a condenser, an expansion valve, and an evaporator.

- The refrigerant is compressed by the compressor, which raises its temperature and pressure.

- The hot, high-pressure refrigerant then flows to the condenser, where it releases heat to the surroundings and condenses into a liquid. This heat transfer occurs as the high-temperature refrigerant gives off heat to the surrounding environment, which can be a liquid or a gas.

- Next, the liquid refrigerant passes through an expansion valve, which reduces its pressure and temperature, causing it to evaporate into a gas. As the refrigerant evaporates, it absorbs heat from the surroundings. This process of heat absorption cools the surroundings while warming the refrigerant.

- The low-pressure refrigerant gas then flows back to the compressor, where it is compressed again and the cycle repeats.

- By using the refrigerant to absorb heat from a low-temperature stream, such as the air outside or a process stream, and then releasing that heat to a high-temperature stream, the heat pump cycle can transfer heat from a low-temperature stream to a high-temperature stream.

In summary, the heat pump cycle for heating works by compressing and expanding a refrigerant, which allows for the transfer of heat from a low-temperature stream to a high-temperature stream. The compressor raises the temperature and pressure of the refrigerant, while the condenser releases heat to the surroundings, and the evaporator absorbs heat from the low-temperature stream.

Carnot heat pump

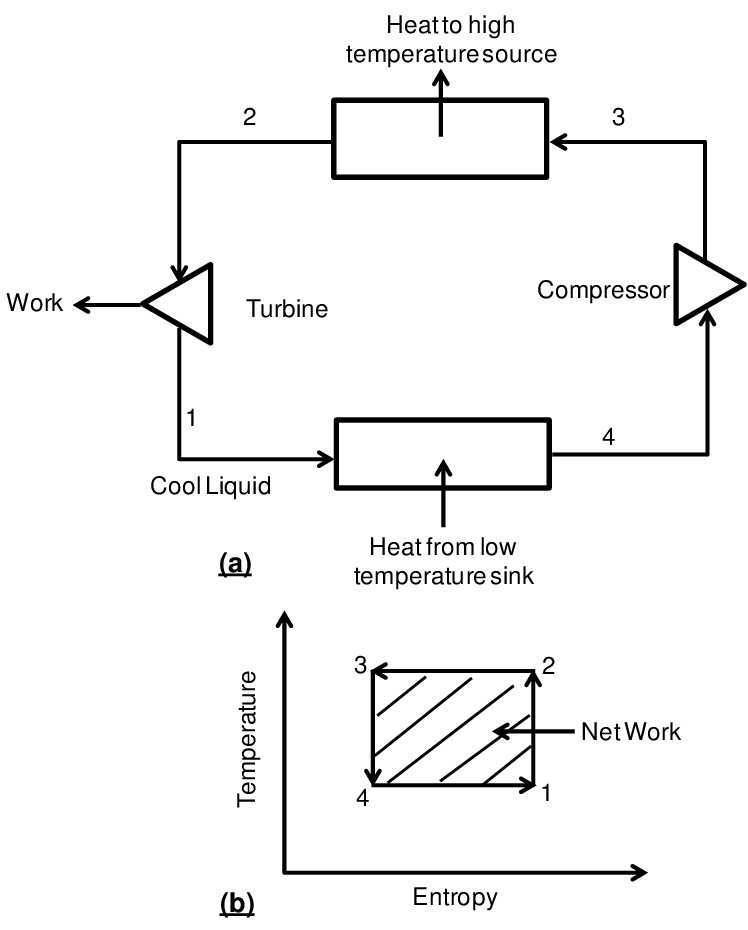

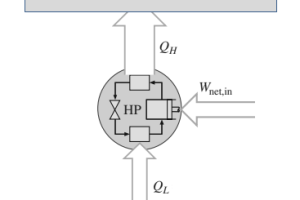

A Carnot heat pump is a theoretical heat pump that operates on the reverse Carnot cycle. The reversed Carnot cycle, also known as the Carnot refrigeration cycle, is a theoretical thermodynamic cycle that is the most efficient refrigeration cycle possible. It operates by transferring heat from a low-temperature reservoir to a high-temperature reservoir by using the least amount of work possible.

The reversed Carnot cycle consists of four stages, which are the exact opposite of the stages in the Carnot power cycle.

- The working fluid is compressed isentropically, which raises its temperature and pressure.

- Then, the working fluid passes through a heat exchanger where it rejects heat to the high-temperature reservoir at constant pressure.

- Next, the working fluid undergoes isentropic expansion, which lowers its temperature and pressure.

- Finally, the working fluid passes through another heat exchanger where it absorbs heat from the low-temperature reservoir at constant pressure.

The efficiency of the reversed Carnot cycle is defined as the ratio of the heat absorbed from the low-temperature reservoir to the work input required. The efficiency of the cycle is limited by the temperature difference between the high- and low-temperature reservoirs, with a larger temperature difference leading to a higher efficiency.

While the reversed Carnot cycle is a theoretical construct and not practical for everyday use, it serves as a useful benchmark for comparing the efficiency of real-world refrigeration cycles.