Efficiency of Power Generation Plant - Three types of important efficiencies are considered for each power generation plant. Economic efficiency of a power plant deals with the cost of producing specific quantity of useful power or electricity. Operational efficiency of a power plant measures the actual output compared to potential maximum output. Energy efficiency of a power plant deals with ratio of useful output energy to input heat energy.

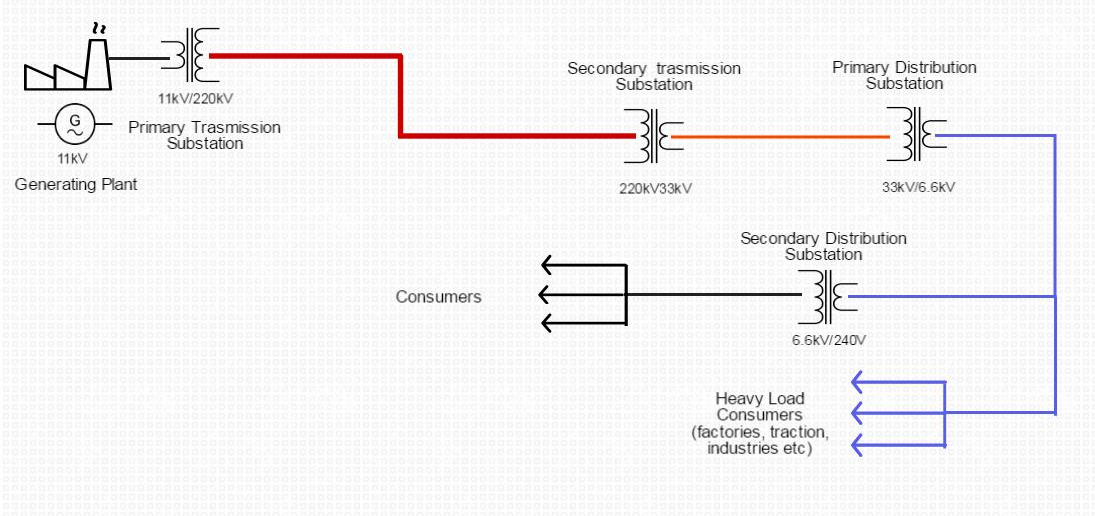

Electrical transmission & distribution substations - The electricity which is generated in the power plants needs to be transmitted and distributed over large distances of 100s and 1000s of kms before it meets the end user/customer. For this purpose transmission and distribution lines are established and an electrical network is established across the entire country.

Electrical transmission & distribution substations - The electricity which is generated in the power plants needs to be transmitted and distributed over large distances of 100s and 1000s of kms before it meets the end user/customer. For this purpose transmission and distribution lines are established and an electrical network is established across the entire country.

Electrostatic Precipitators – Electrostatic precipitators (ESPs) are industrial emissions control units that are typically installed at coal power plants. Their purpose is to collect and remove dust particles from the exhaust flue gas of a power plant at a typical efficiency level of 99.9% or more. Electrostatic precipitators work by placing a positive charge on a group of plates installed at the exhaust gas stream.

Electrostatic Precipitators – Electrostatic precipitators (ESPs) are industrial emissions control units that are typically installed at coal power plants. Their purpose is to collect and remove dust particles from the exhaust flue gas of a power plant at a typical efficiency level of 99.9% or more. Electrostatic precipitators work by placing a positive charge on a group of plates installed at the exhaust gas stream.

Fire Protection for Power Plant -NFPA 850 provides recommendations for fire protection for fossil fueled or alternative fueled power generation plants. A fire area determination should be carried out in the first place. Fire area boundaries should be created in order to separate critical areas like cable spreading rooms-tunnels, control rooms, computer rooms, switchgear rooms, battery rooms, warehouses, fuel oil facilities and boilers, fuel tanks -containers etc. from adjacent areas.

Fire Protection for Power Plant -NFPA 850 provides recommendations for fire protection for fossil fueled or alternative fueled power generation plants. A fire area determination should be carried out in the first place. Fire area boundaries should be created in order to separate critical areas like cable spreading rooms-tunnels, control rooms, computer rooms, switchgear rooms, battery rooms, warehouses, fuel oil facilities and boilers, fuel tanks -containers etc. from adjacent areas.

Power plant based on Combined Cycle - Following different steps are involved in a combined cycle power plant. (1) Atmospheric air is compressed and sent to combustor, to burn fuel. (2) The resulting gases at very high temperature enter into gas turbine. (3) Exhaust gases from gas turbine at 500 – 5500C pass through heat recovery steam generator (HRSG) to boil water using the residual heat. (4) Steam generated from this residual heat drives steam turbine and exhaust from steam turbine is fed to the condenser. Condensed water is again pumped back to the HRSG.

Power plant based on coal - Coal gasification based power plant works through following sub processes. (1) Treated water from condenser is pumped to a boiler. (2) Boiler uses coal or syn gas to boil the water to produce superheated steam. (3) Superheated steam from boiler expands in stream turbine to generate power. (4) Steam outlet from turbine is condensed, mixed with make-up water and sent to pump to be pumped back to boiler.

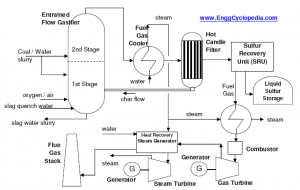

Typical PFD representation of an IGCC Power Plant - A typical a process flow diagram (PFD) of an Internal Gasification Combined Cycle (IGCC) power plant . Coal is first slurried with water and fed to gasifier. Raw syngas exits the gasifier at temperature and is cooled in a fire tube boiler. This gas is further filtered and processed to remove sulfur content. Then the gas is combusted and pushed through a gas turbine to generate power. Residual heat from the flue gas at turbine exit is used in a 'Heat Recovery Steam Generator' to produce steam which generates more power in a steam turbine.

Typical PFD representation of an IGCC Power Plant - A typical a process flow diagram (PFD) of an Internal Gasification Combined Cycle (IGCC) power plant . Coal is first slurried with water and fed to gasifier. Raw syngas exits the gasifier at temperature and is cooled in a fire tube boiler. This gas is further filtered and processed to remove sulfur content. Then the gas is combusted and pushed through a gas turbine to generate power. Residual heat from the flue gas at turbine exit is used in a 'Heat Recovery Steam Generator' to produce steam which generates more power in a steam turbine.