The wellhead acts as a gateway between the subsurface reservoir and production facilities at the surface. It is responsible for containing high pressure fluid which is crude oil within the wellbore. It prevents any uncontrolled release of oil or gas and serves as mechanical and pressure seal. It provides a secure connection point for the casing and tubing strings, which is very crucial for maintaining well integrity. Wellhead also acts as an interface for various production control equipment. This guide explores the topic of wellhead in detail.

Table of content:

1. What is a Wellhead?

2. Wellhead Functions

3. Parts of Wellhead

What is a Wellhead?

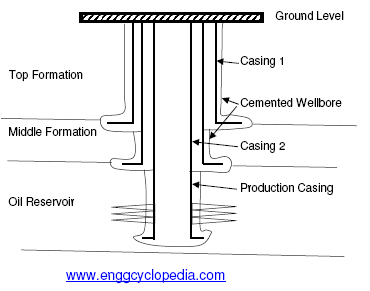

Wellhead consists of components of an oil well that are located above the surface. Wellhead acts as an interface between the casing strings in oil wellbore and surface facilities. The wellhead provides suspending point for the casing strings running through the wellbore. Casing strings are connected sets of series of steel pipes which run through the wellbore from wellhead to the oil reservoir. It is designed to withstand high pressure and acts to contain the pressure inside the casing strings. Wellhead also provides a point of access for well operations.

Wellhead Functions

- Wellheads are also responsible for containing the pressure within each of the casing strings. During oil well drilling, casing is installed and cemented to the wellbore for containing the pressure and wellbore wall in place. Casing also serves to avoid mixing of fluids from different formations through which the wellbore runs.

- A well head provides means for suspension of casing strings running down the wellbore.

- A Blow Out Preventer (BOP) acts to cope up with erratic fluctuations of pressure and flow from reservoir. Wellhead serves as attachment point for the Blowout Preventers.

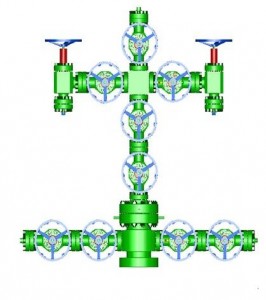

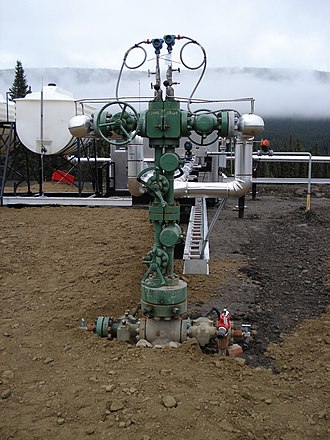

- Well head provides means for attaching a Christmas tree for production operations. Christmas tree is equipped with set of isolation and choke valves and serves for pressure control.

- Tubings are passed through the casing from surface to the oil reservoir to facilitate the transfer of fluids to the surface. The tubings responsible for oil production are called production tubings. A well head also provides a point for suspension of tubings.

- Wellhead can be used for pressure monitoring for casings and annuli between different casing and tubing strings.

- Sometimes multiple casings are used in the same wellbore. These casings contain different well fluids. A wellhead serves to keep these casings separated from each other to avoid mixing of fluids.

- Wellheads also provide access for pumping from annuli between the different casing/tubing strings.

- Well head provides reliable access to well with possibility to attach a well pump.

Parts of Wellhead

Casing Head: It is the uppermost component of wellhead system. It provides a connection point for the well casing strings and supports the weight of the casing. The casing head typically includes flanged or threaded connections for attaching the casing.

Casing Spools: These are intermediate components placed between the casing head and casing hanger. These components provide additional support and sealing for casing strings. It consist of flanged or threaded connections that allows attachment of other wellhead components.

Casing Hangers: These devices suspend and seal casing strings within the wellhead. Casing hangers are installed within the casing spools.

Choke Manifold: A choke manifold is used to decrease the pressure originating from the wellhead. It comprises a collection of valves designed to handle high pressure, along with a minimum of two chokes. These chokes can either be fixed or adjustable, or a combination of both. The inclusion of redundant chokes is necessary to ensure that if one choke becomes inoperable, the flow can be redirected through another.

Packoff (Isolation) Seals: Packoff seals are used to isolate different zones within the well and prevent fluid communication between them. These seals are typically made of elastomers or metal and are installed between casing strings or tubing strings. These components ensure proper zonal isolation and prevent fluid migration.

Test Plugs: These devices isolate the specific section of the well temporarily. Test plugs are inserted into casing or tubing to block the flow of drilling fluid temporarily. This is useful for conducting pressure test.

Mudline Suspension Systems: It is used in offshore drilling to support the wellhead on seabed.

Tubing Head: Tubing heads are installed below the casing head and provide a connection point for the production tubing. They are designed to support and seal the tubing string which allows the flow of oil or gas from the well to the surface.

Tubing Hangers: Tubing hangers are devices that suspend and seal the production tubing within the tubing head. They are typically installed inside the tubing head and provide a reliable connection between the tubing and the wellhead.

Tubing Head Adapter: The tubing head adapter is a component used to connect the tubing head to the Christmas tree or other production equipment. It allows for a smooth transition and secure attachment between the tubing head and the surface production facilities.