It is very important to know about different types of safety valves and their P&ID symbols, especially for process engineers. Because safety valves are important components in process industries to protect equipment and personnel from overpressure situations.

This post contains commonly used P&ID symbols (Piping and Instrumentation Diagram symbols) for safety valves. Note that they may differ slightly from one project to another.

Table of content:

Pressure Relief Valve

Vacuum Relief Valve

Breathing Valve or Pressure/Vacuum Relief Valve

Pilot-operated relief valve

Pressure Rupture Disc

Vacuum Rupture Disc

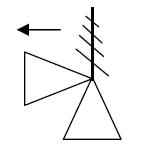

Pressure Relief Valve

This is the most common type of safety valve used to relieve a system's excess pressure. These valves are designed to open automatically when the pressure in a system exceeds a set point, allowing excess pressure to be safely released. The arrow represents the direction in which the valve will open to relieve pressure.

This valve typically functions by allowing the pressurized fluid to escape from an auxiliary passage, which redirects the fluid out of the system, thereby decreasing the pressure to safe levels. This process ensures that the system maintains safe operating conditions and prevents damage or failure caused by excess pressure.

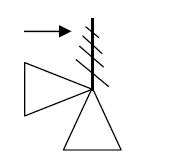

Vacuum Relief Valve

A vacuum relief valve is a safety device that is designed to protect equipment from damage caused by excessive vacuum or negative pressure. The valve works by allowing air or another gas to enter the system when the pressure drops below a certain threshold, thereby relieving the vacuum. This is achieved through a spring-loaded valve mechanism that opens when the pressure drops below the set point. The arrow in the P&ID symbol of the vacuum relief valve represents the direction in which the valve will open to relieve the vacuum.

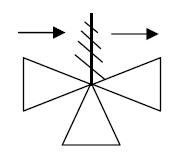

Breathing Valve or Pressure/Vacuum Relief Valve

Breathing valves protect tanks from excess pressure and vacuum conditions. Additionally, they minimize evaporation loss. They are widely used in the protection of bulk storage tanks with floating covers. Breathing valves are designed to automatically open and relieve pressure or vacuum conditions within a specific range. This is achieved by using weighted pallets or springs to control the pressure and vacuum protection levels.

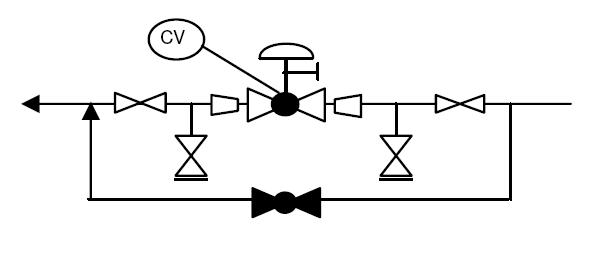

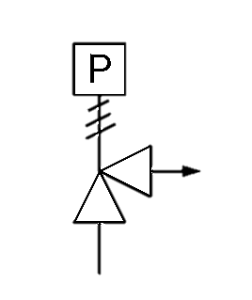

Pilot-operated relief valve

The pilot operating relief valve works by keeping the valve shut with a small amount of fluid piped to the back of the sealing disk, with the pressure balanced on both sides. If the pressure in the system reaches a certain threshold, a separate actuator on the piping will release pressure in the line. This causes the pressure on the back of the seal to be released, which in turn opens the valve and allows the excess pressure to be released from the system.

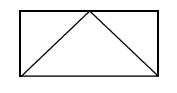

Pressure Rupture Disc

The pressure rupture disc typically consists of a thin, metal disc that is designed to rupture at a predetermined pressure. This allows the excess pressure to be safely released from the system. Additionally, it is installed in the system in parallel with a relief valve to provide a secondary safety device. It ensures that overpressure conditions are detected and relieved. By rupturing at a predetermined pressure, the pressure rupture disc acts as a fail-safe device.

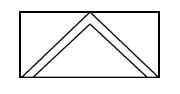

Vacuum Rupture Disc

A vacuum rupture disk is a safety device designed to protect equipment from the potentially damaging effects of excessive vacuum. It is a thin, metal disk. It is designed to rupture at a predetermined vacuum level. This allows air to enter the system and relieve the vacuum.

Check this post to study pressure safety valve typical P&ID arranement.