Pressure relief devices are used for protection of pressure vessels from over pressure damage. This post discusses key terminology for relief devices that help better understand the design and usage of these pressure relief devices.

Table of content:

1. Maximum Operating Pressure

2. Design Pressure

3. Maximum Allowable Working Pressure (MAWP)

4. Set Pressure

5. Accumulation Pressure

6. Overpressure

7. Blowdown

Maximum Operating Pressure

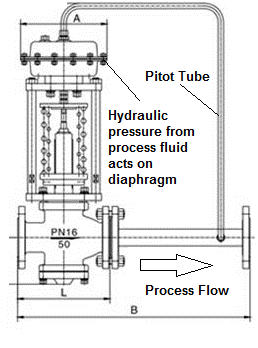

This is the maximum value of pressure, expected during normal operating of the vessel. This means that maximum operating pressure is highest pressure at which vessel is designed to operate safely. It is very important to operate within specified limit of maximum operating pressure to prevent equipment failure or hazardous situation. Exceeding the limit of maximum allowable pressure may result in catastrophic failure. Pressure relief valves are installed to relieve excess pressure in such overpressure situations by relieving excess pressure from the vessel.

Design Pressure

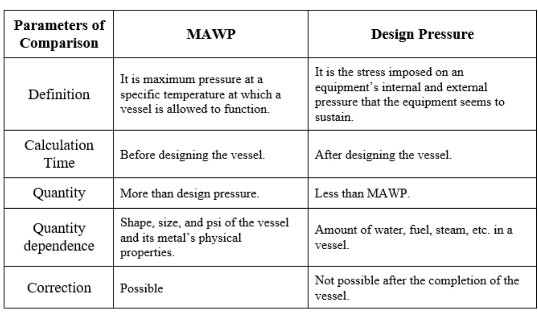

Design pressure for a vessel is taken by adding a suitable margin to the maximum possible pressure during normal operation. This design pressure value is used to determine the minimum thickness for all vessel elements, by applying vessel design rules to the design pressure. Design pressure is less than or equal to the Maximum Allowable Working Pressure (MAWP). When MAWP value for a fabricated value is not available, design pressure value should be used as a conservative replacement for MAWP.

Maximum Allowable Working Pressure (MAWP)

The maximum allowable working pressure is the highest pressure that the vessel can withstand based on actual nominal vessel thickness excluding the allowances provided for corrosion and loadings other than pressure. MAWP has to be at the least equal to design pressure. MAWP is commonly calculated for a fabricated vessel. During fabrication, availability of materials and thickness of material used usually leads to a vessel exceeds the minimum requirements imposed by design pressure. For such a vessel the MAWP is greater than design pressure. For a vessel which only meets the minimum requirements imposed by design pressure, MAWP is equal to the design pressure.

Check this post to explore details of Maximum Allowable Working Pressure along with the difference between MAWP and design pressure.

Set Pressure

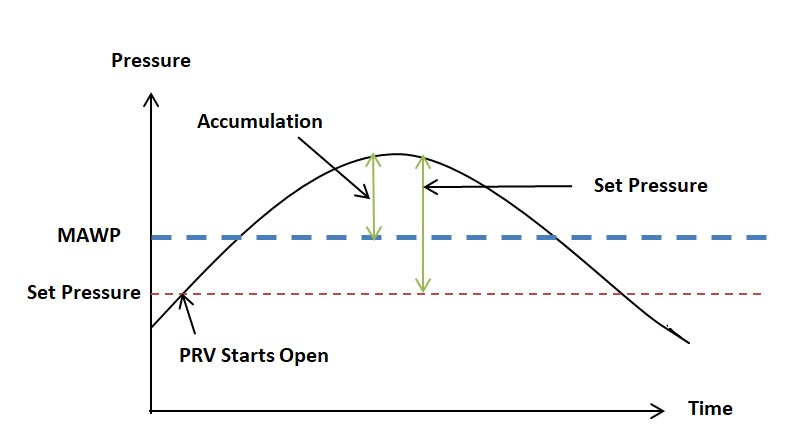

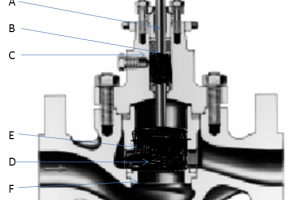

Set pressure of a relieving device on a pressure vessel is the pressure when the relieving device just starts to open. Set pressure is also known as setpoint or popping pressure. Set pressure ensures that the valve opens at desired pressure to prevent overpressure situation. Pressure relief valve remains open until the pressure of the vessel drops below the set pressure. After that relief valve closes again.

Accumulation Pressure

Maximum allowable accumulated pressure is specified for a vessel protected by a pressure relief device. It is the maximum allowable pressure during discharge from the relieving device. Accumulation pressure refers to the maximum pressure that can build within the vessel when all relief devices are fully closed.

This pressure is commonly expressed as a percentage of Maximum Allowable Working Pressure (MAWP). This percentage is determined by the governing case for opening of the relief valve protecting the vessel. For instance, vessel protected for fire case has a maximum allowable accumulated pressure which is 121% of the MAWP. This means that the pressure inside the vessel is allowed to rise to 121% of the MAWP before the relief valve opens to release the pressure.

Overpressure

Overpressure is an important terminology for relief devices. Overpressure is similar to pressure accumulation value described above. The difference is that overpressure is reported as a percentage of the set pressure of relieving device. If the relieving device is set to open at Maximum Allowable Working Pressure (MAWP), then overpressure becomes equal to accumulation pressure.

This refers to the maximum pressure that the pressure relief valve can handle or relieve during an overpressure event. It represents the allowable increase in pressure above the valve's set pressure before it reaches its maximum capacity or safety limit.

Blowdown

Overpressure is also an important terminology for relief devices. Blowdown is the pressure when the pressure relief valve closes this discontinuing the relieving flow. This pressure value is lower then the set pressure and is commonly reported as a percentage of the set pressure value.

Blowdown is necessary to prevent the valve from chattering. Chattering is a condition in which the valve opens and closes rapidly, which can damage the valve and the system it is protecting. Blowdown allows the system pressure to drop below the set pressure before the valve closes, which prevents chattering.

Check this post to explore superimposed back pressure, built up back pressure and cold differential test pressure (CDTP).