Self-actuated pressure control valves are devices designed to regulate pressure within a system without the need for external power or control signals. It operates based on the principle of utilizing the process fluid's energy to open or close the valve and maintain the desired pressure level. This self-actuation mechanism simplifies the control system, reducing the complexity and costs associated with external power sources or control instruments.

Table of content:

1. Self actuated pressure control valve

2. Backpressure control valve

3. Structure of a self actuated pressure control valve

Self actuated pressure control valve

Self-actuated pressure control valves are a type of valve that uses the pressure of the fluid flowing through the valve to control the opening and closing of the valve. This type of valve does not require any external power source, such as electricity or pneumatics, to operate.

Self-actuated pressure control valves are typically used in applications where constant pressure is required, such as in boiler feedwater systems and chemical processing plants. They can also be used to protect equipment from overpressure or to prevent the flow of fluids in hazardous areas.

If pressure at the immediate downstream point of the valve is used as a signal to throttle the control valve, then the downstream pressure is maintained at a specified set point and such valves are known as pressure regulator valves.

Self-actuated pressure control valves are a versatile type of valve that can be used in a variety of applications. They are reliable, easy to maintain, and relatively inexpensive.

Here are some additional details about self-actuated pressure control valves:

- They are available in a variety of sizes and materials, to meet the specific needs of each application.

- They can be operated manually or automatically, and can be actuated by a variety of methods, such as handwheels, pneumatic actuators, or electric actuators.

- They are relatively inexpensive, making them a cost-effective option for many applications.

If you are looking for a reliable and versatile type of valve, a self-actuated pressure control valve may be a good option for you.

Backpressure control valve

A backpressure control valve, also known as a back pressure regulator, is a type of self actuated pressure control valve used to control the pressure in a system by regulating the flow of fluid or gas. It is designed to maintain a specific back pressure in a process line, downstream of the valve, regardless of changes in the upstream pressure.

If the pressure upstream to the valves is used to throttle the control valve, then the upstream pressure is maintained at a specified set point and such a valve is known as a backpressure control valve, as it maintains the backpressure imposed by the control valve.

The backpressure control valve operates by automatically adjusting its position to balance the downstream pressure against a reference pressure or a setpoint. When the downstream pressure exceeds the desired level, the valve opens to allow fluid or gas to escape, reducing the pressure. Conversely, if the downstream pressure drops below the setpoint, the valve restricts the flow to maintain the desired back pressure.

Structure of a self actuated pressure control valve

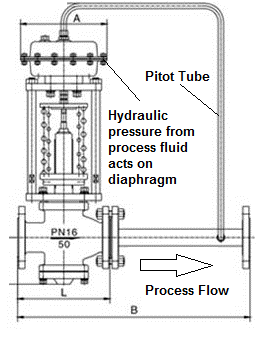

As figure indicates, a self actuated pressure control valve uses a pitot tube which gives access to process fluid to pressurize the diaphragm which then acts to open the valve so process fluid from process line can pass through.

For a pressure regulator valve, the pitot tube connects the diaphragm casing to a point downstream of the control valve. When the pressure downstream to the control valve increases beyond the setpoint, process fluid exerts increased pressure on the diaphragm thus closing the valve. Closing of the valve stops process flow thus reducing the valve downstream pressure back to setpoint level. When the pressure downstream of the control valve drops below the setpoint level, process fluid from diaphragm casing recedes back to process line. This relieves pressure on diaphragm and opens the valve to allow increased process flow. Increased process flow leads to increase in pressure back to its setpoint.

For a back-pressure regulator valve, the pitot tube connects diaphragm casing to a point upstream of the pressure control valve and the process fluid from upstream point acts on the valve diaphragm to open or close the valve in case of high or low pressure respectively.