Centrifugal pumps are among the important equipment in any process plant. In any refinery they are considered to be equivalent to heart of a refinery, as they keep the flow running with a certain pressure and quantity from one place to another, each pump has its own pump performance curve.

Pump performance curve

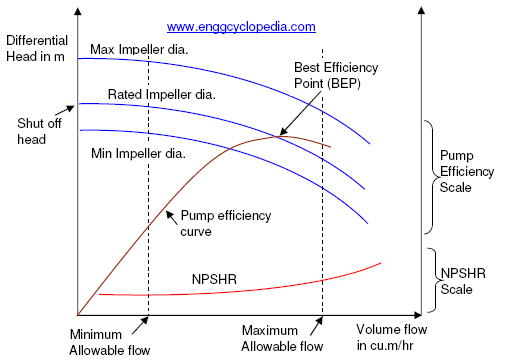

A performance curve is plotted to indicate the variation of pump differential head against volumetric flow (gpm) of a liquid at an indicated rotational speed or velocity, while consuming a specific quantity of horsepower (BHP). The performance curve is actually four curves relating with each other on a common graph. These four curves are:

- The Head-Flow Curve. It is called the H-Q Curve.

- The Efficiency Curve.

- The Energy Curve. It records Brake Horsepower, BHP.

- The Pump’s Minimum Requirement Curve. Its called Net Positive Suction Head required, NPSHr.

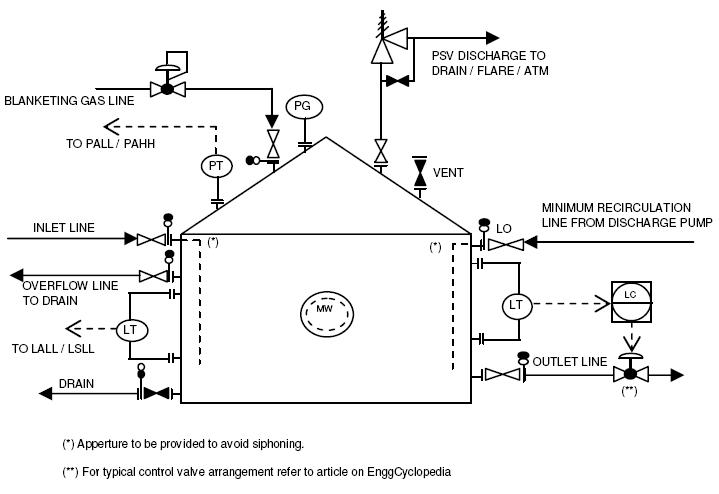

Figure-1 present a sample pump performance curve image with all the important curves shown.

A detailed explanation of how to read and use the pump curves for testing can be found here.

Typical Procedure of Pump Performance Test

The purpose of pump performance test is to ensure that the actual performance of a pump is typical to that set by supplier. Typical steps to be followed to conduct a pump performance test are outlined below.

- Prepare the original pump curve sent by supplier.

- Make sure that the suction strainer is clean and the suction valve is fully open.

- Ensure that discharge valve is fully closed.

- Start the centrifugal pump take the reading of the discharge pressure, flow rate, suction pressure and pump Ampere. (Finish this procedure in less than 1 min. As not to damage the internal parts of the pump)

- Open the discharge valve slightly till the flow rate reaches the first value indicated in pump performance curve provided by pump supplier.

- Write down the discharge pressure, flow rate, suction pressure and pump Ampere.

- Increase the opening of the discharge valve till you reach the next value indicated in pump performance curve provided by pump supplier.

- Open the discharge valve in small increments until it is fully open and take the readings of the discharge pressure, flow rate, suction pressure and pump Ampere at each of the steps.

Write down all the reading you take in a table as shown:-

| 1 | 2 | 3 | 4 | 5 | |

|

Q(m3/hr) |

|||||

|

Suction P(bar) |

|||||

|

Discharge P(bar) |

|||||

|

Differential head(m) |

|||||

|

Ampere |

Compare the curve plotted from pump performance test readings (table) with the performance curve sent by supplier and observe for any differences. If you witness any deviation try to locate the problem and fix it then repeat the test and compare the results.