Heat exchanger fouling is a commonly occurring problem in different kinds of heat exchangers. It results in changing the heat transfer surface and reducing the overall heat transfer rate through that surface.

During fouling, the surface of a heat exchanger wall develops another layer of solid material. This can happen for a variety of reasons. But as a result, the heat transfer coefficient at the surface is drastically reduced, since the heat conducting wall metal is not in contact with the fluids any more. Instead, the wall is separated from fluid by a layer of 'fouling'. Fouling material prevents efficient heat transfer and reduces the efficiency of heat exchanger.

Let's then look at why fouling occurs in a heat exchanger to begin with. There are a few different reasons. They make up for different types of fouling.

Table of content:

Corrosion fouling

Particulate fouling

Precipitation fouling

Chemical reaction fouling

Bio fouling

Freezing fouling

Preventing heat exchanger fouling

Cleaning of the heat exchanger fouling

Why to put the fouling or corrosive fluid on tube side?

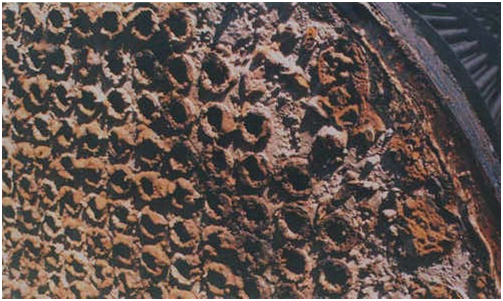

Corrosion fouling

Corrosion fouling occurs when the fluid corrodes the surface of the exchanger wall, developing a layer of corrosion. The accumulation of corrosion products can act as an insulator. It leads to increased energy consumption and reduced heat exchanger efficiency.

Particulate fouling

Particulate fouling happens when there is low fluid velocity in certain areas of the fluid path. Because of the low fluid velocity, suspended particulate matter in the fluid can settle down on the heat exchanger wall. Over time a layer of such particulate material develops on the wall, reducing the heat transfer through it.

Precipitation fouling

Precipitation fouling occurs when the fluid flowing through the heat exchanger contains dissolved solids that can react and precipitate out of solution under certain conditions, such as changes in temperature, pressure, or chemical composition. Precipitation fouling also occurs because of deposition of material which was originally in the fluid stream. In that respect, it is similar to particulate fouling.

But in most cases of precipitation fouling, the dissolved matter in the fluid starts to precipitate due to change in fluid temperature. The change in temperature is highest at the heat exchanger wall. Hence some dissolve solids can precipitate out of the fluid and get deposited on the exchanger wall, resulting in fouling.

Chemical reaction fouling

Chemical reaction fouling in heat exchangers refers to the buildup of reaction products on the surfaces of the heat exchanger, which can reduce its efficiency and cause damage. If the fluid flowing through the exchanger contains reactive species then the fluid can undergo a reaction at the heat exchanger wall surface. This reaction produces a solid product that adheres to the heat exchanger wall, resulting in fouling - for example, polymerization.

Note that this is different than the 'corrosion fouling', where the wall itself gets corroded. In case of chemical reaction fouling, the wall is chemically unchanged. But the fluid undergoes a reaction, producing fouling material.

This kind of fouling also happens because of temperature change in the fluid. High temperature change at the exchanger wall causes the fluids to react.

Bio fouling

Biofouling occurs when microorganisms, such as bacteria, algae, or fungi, grow and form colonies on the metal surfaces inside the heat exchanger. Organisms present in the fluid stream can get attracted to the warm surface of the heat exchanger wall. Here they can grow in size and reproduce, forming a layer of biological material. This is known as 'bio fouling'.

Freezing fouling

Some times the fluid temperature near the heat exchanger walls can drop so low that some of the fluid freezes. This frozen solid remains on the heat exchanger wall. But it is not as conductive as the exchanger wall and it restricts the heat transfer across the wall, resulting in freezing fouling. This type of fouling occurs when the fluid flowing through the heat exchanger drop below its freezing point and the exchanger surfaces are cold enough to freeze the fluid.

This is similar to precipitation fouling. But instead of solids precipitating out, the fluid itself solidifies in this kind of fouling.

Preventing heat exchanger fouling

We can take certain measures to prevent the fouling in an exchanger. These measures are directly related to what kind of fouling is occurring in the exchanger. Hence it is important to first identify the cause of fouling and then take one of the following measures depending on the type of fouling.

- In case of corrosion fouling, better corrosion resistant material can be used. It is advisable to make a cost analysis of corrosion resistant material cost vs the cost of maintaining/replacing the exchanger material.Ak

- Precipitation fouling occurs due to low fluid velocity in certain areas in the heat exchanger. Hence it can be minimized by maintaining higher fluid velocity. In case of water, it is recommended to maintain fluid velocity around 1 m/s levels. Sometimes higher velocities will result in higher pressure drop across the heat exchanger.

- In case of shell and tube heat exchangers, the fluid on the shell side flows across a bundle of tubes. It is not possible to maintain uniformly high velocity on the shell side. There would always be some low velocity areas on the shell side. Hence if there is possibility of precipitation fouling on the shell side, it is advisable to provide 25-30% more surface area to compensate for the eventual fouling on the shell side.

- We can contain the Bio fouling in a heat exchanger by using copper alloy material or by using chemical treatment of the fluid to minimize biological growth within the fluid.

- Freezing fouling, precipitation fouling and reaction fouling mainly originate because of the change in the fluid temperature. If the temperature difference between the heat exchanger wall and fluid is high, then the fluid close to the wall is most likely to cause fouling because of high temperature change. We can minimize this by lowering the temperature difference between exchanger wall and fluid. But if the temperature difference is lower, then additional surface area must be provided to maintain the same heat transfer rate. This can be done by having extended surface at the wall - for example, finned tubes.

Cleaning of the heat exchanger fouling

We can use following methods for cleaning the fouling and scaling from exchanger surface.

- Deposits which are weakly attached to the exchanger wall can be washed off by operating the exchanger at higher fluid velocity. Or we can also flush the exchanger with a water or steam flow.

- Other fouling materials can be chemically cleaned using suitable solvents or weak acid solutions.

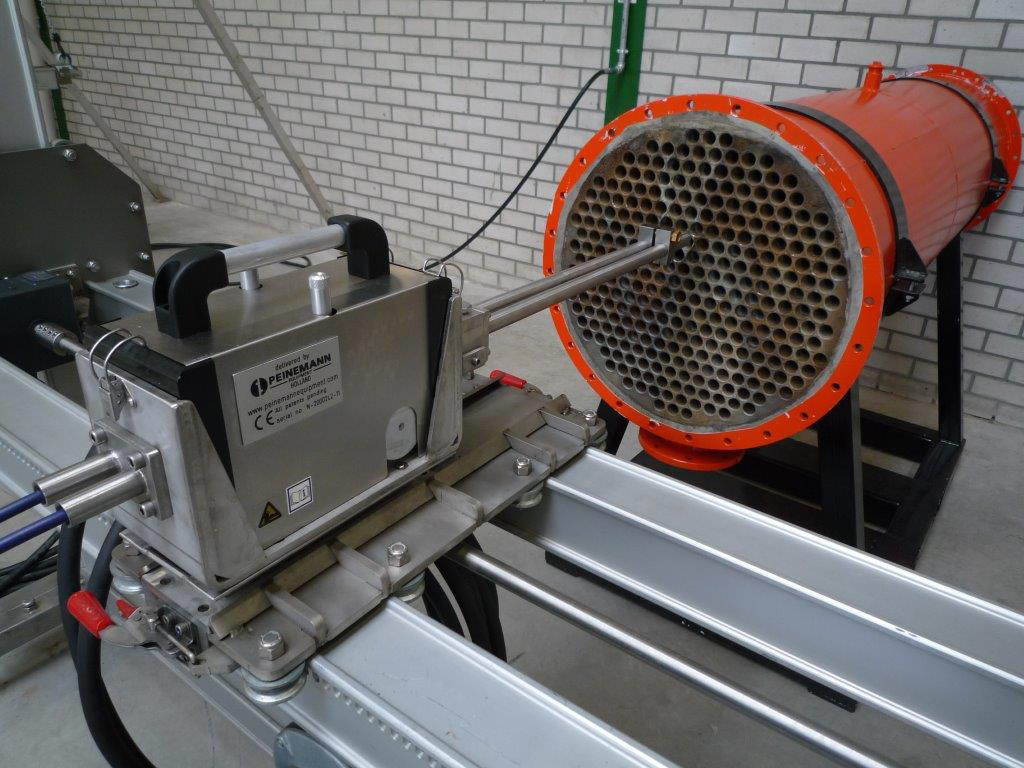

- But many times, chemical cleaning or flushing is not enough. We can clean the heat exchanger surface mechanically, using techniques such as - rodding, turbining, scraping etc.

- In case of shell and tube heat exchanger, it is much easier to mechanically clean the inside of the tubes than to clean the shell side. Hence, generally the dirty or fouling fluid is kept on the tube side. We can clean the tubes from inside without taking out the tube bundle. But it is necessary to remove the tube bundle to clean shell side. Even then, it is difficult to clean the outer surface of the tubes because of bundled arrangement of the tubes.

Why to put the fouling or corrosive fluid on tube side?

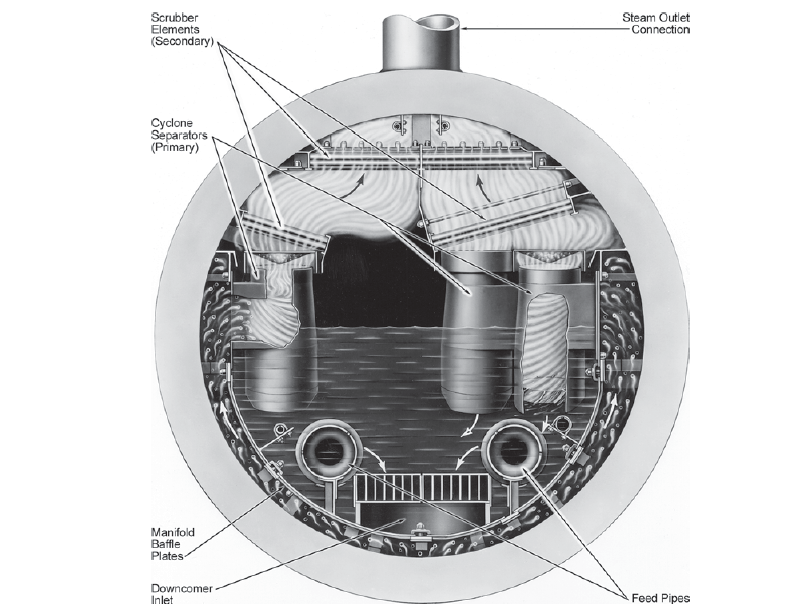

When you design a new shell & tube heat exchanger, you have two fluids - one hot and one cold. You need to decide which one should go to shellside and which one should be put through the tube side. Fouling or corrosive fluids are typically placed on the tube side of a heat exchanger because they can cause damage to the shell side, which is typically made of less durable materials.

If a fluid is particularly dirty, corrosive or causes heat exchanger fouling, it has the biggest impact the 'maintainability' aspect from the 3 important factors listed above.

Hence a dirty, fouling or corrosive fluid is generally put on the tube side of a shell & tube heat exchanger, because -

- It is easier to mechanically clean the inner surface of the tubes, in a shell & tube exchanger.

- Mechanical cleaning of the inner shell surface or outer walls of the tubes is much more difficult in comparison.

- Tubes are relatively cheaper to fabricate than the shell side. Hence even if a corrosive fluid eats up the inside of those tubes in the long run, they can be replaced at a lower cost than the shell side material.

- Tubes made of expensive corrosion resistant material can be cheaper than the entire shell built out of special material.

Mechanical cleaning of the tubes

In two out of three categories of shell & tube exchangers, the tube bundle can be easily cleaned from the inside by removing the read end head. In fixed tubesheet and floating head type of exchangers this is easily possible. Hence these types are preferred when there is a dirty or corrosive service involved.

Other fluids recommended to be kept on tube side

Apart from the corrosive or dirty fluids, it is also preferred to put the following types of fluid services on the tube side of an exchanger.

- High pressure fluids are kept on the tubeside. Tubes of higher pressure rating are cheaper than the shell side of a higher pressure rating.

- Toxic fluids are also kept on the tubeside to minimize the possibility of leakage to environment

- Streams with low allowable pressure drops are put on the tubeside, where turbulance and resulting head loss can be minimized.