Motor operated valves (commonly abbreviated as MOV on P&IDs) are valves which are actuated by electric motors. Motor operated valves are generally large valves used in different kinds of operations. Due to the large size of the valve actuator, an electric motor is needed to open or close a valve. Different types of motor operated valves are defined based on how those valves are actually opened or closed and what applications they are used for.

Types of motor operated valves are actually dependent on what kind of flow control can be achieved with these automated valves. This post contains detailed discussion ontypes of motor operated valves.

Table of content:

1. Motor operated valve types

1.1. Open / Close valves

1.2. Inching valves

1.3. Precision flow valves

2. Different type of valves with motorized actuators

2.1. Motor operated gate valve

2.2. Motor operated butterfly valve

2.3. Motor operated ball valve

Motor operated valve types

Open / Close valves

Open/close valves are used to turn the flow of a fluid on or off. They are not designed for precise flow control, but rather to provide a simple and reliable way to stop or start the flow of a fluid. Motors are used to open and close the valves, which can be helpful in applications where the valves are large or difficult to operate manually.

Some examples of applications where open/close valves are used include:

- Pump discharge/suction valves: These valves are used to control the flow of fluid into and out of a pump.

- Boiler feed water isolation valves: These valves are used to isolate the boiler from the water supply.

- Drum vent valves: These valves are used to release steam from the drum of a boiler.

- Product line valves: These valves are used to control the flow of product from a production line.

Open/close valves are a versatile type of valve that can be used in a variety of applications. They are simple to operate and maintain, and they can be used to control the flow of a wide range of fluids.

Inching valves

Inching valves are used to open and close valves gradually, in small steps. These valves offer more precise flow control compared to the on/off valves. Motorized actuator facilitates gradual opening and closing of the valve enabling some degree of control over the flow. Some examples include, reflux lines, boiler start up vent, boiler IBD valves, boiler main steam valves etc.

Some examples of applications where inching valves are used include:

- Reflux lines: Reflux lines are used to return a portion of the condensate from a distillation column back to the column. The flow rate of the reflux is controlled by a throttling valve, which ensures that the desired temperature and composition of the distillate is maintained.

- Boiler start-up vent: A boiler start-up vent is used to release steam from the boiler during the start-up process. The flow rate of the steam is controlled by a inching valve, which prevents the boiler from over pressurizing.

- Boiler IBD valves: IBD valves are used to control the flow of water into a boiler. The flow rate of the water is controlled by a inching valve, which ensures that the boiler does not overheat.

- Boiler main steam valves: Main steam valves are used to control the flow of steam from a boiler. The flow rate of the steam is controlled by a inching valve, which ensures that the steam is available when needed.

Precision flow valves

Precision flow valves enable precise flow control, better than an inching valve. Motorized actuator in an inching valve operates in steps configured in the controller, e.g. 5%, 10% opening steps. Hence flow control can also be done in brackets of 5-10% with that much margin for error.

On the other hand, in case of precision flow valves, continuous flow control is enabled by the use of proper feedback from the field to the controller which is not usually found in other motor operated valves.

An example is steam injection valve / water injection valves used in GT for Nox control. In this application, the valve is used to inject steam or water into the combustion chamber to reduce the formation of NOx. The amount of steam or water that is injected needs to be very precise in order to achieve the desired NOx reduction. A precision flow valve is used in this application because it can provide the level of control that is required.

Different type of valves with motorized actuators

Types of motorized valves discussed above is based on the flow control capabilities. But that aside, different types of valves, can also be used as motor operated valves by simply using a motorized actuator for any valve.

Some examples of different types of motorized valves are discussed in the following section.

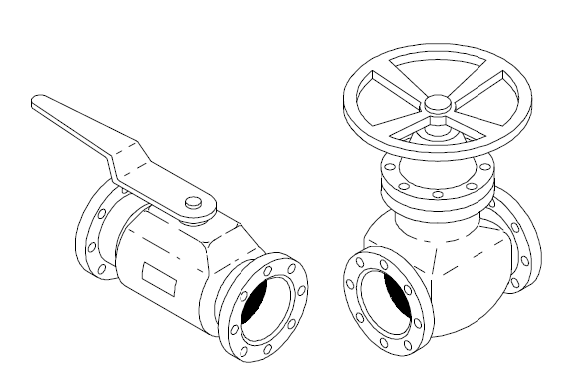

Motor operated gate valve

A motor-operated gate valve is a type of valve that uses an electric motor or actuator to open and close the valve. The motor or actuator attached to the gate valve provides the necessary power to move the gate. The motor receives signals from a control system to move the gate up or down, allowing or blocking the flow.

When the motor is activated, it rotates a threaded stem that is connected to the gate inside the valve. As the stem rotates, it moves the gate up or down, thereby opening or closing the valve. The gate typically moves perpendicular to the flow direction, allowing for a full and unobstructed flow when the valve is fully open.

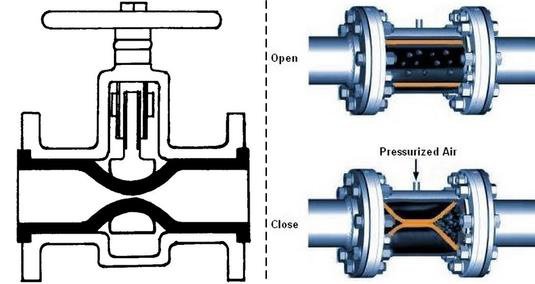

Motor operated butterfly valve

A motor-operated butterfly valve is a type of valve used in industrial applications to control the flow of fluids or gases. It utilizes an electric motor or actuator to open and close the valve by rotating a circular disc. The motor receives signals from a control system to adjust the valve's position. When the motor is activated, it rotates the disc either parallel or perpendicular to the flow direction, allowing or restricting the flow respectively. In the fully open position, the disc aligns with the pipe, creating a straight passage for maximum flow. In the fully closed position, the disc rotates to block the flow completely.

Motor operated ball valve

A motor-operated ball valve is a type of valve that uses an electric motor or actuator to control the opening and closing of a ball valveThe ball valve consists of a hollow sphere or ball with a hole in the center, known as the bore, that allows or restricts the flow through the valve. The motor or actuator attached to the ball valve provides the necessary power to rotate the ball within the valve body.

When the motor is activated, it rotates the ball to align the bore either parallel or perpendicular to the flow direction, allowing or blocking the flow accordingly. In the fully open position, the bore aligns with the pipe, providing maximum flow. In the fully closed position, the bore turns perpendicular to the pipe, stopping the flow completely.