Forced circulation evaporators are widely used in the chemical, food, and pharmaceutical industries for concentrating solutions or suspensions by evaporating the solvent. This type of evaporator is particularly effective for handling materials with high concentrations of solids or viscous materials that are difficult to circulate by gravity alone. This post covers a detailed overview of forced circulation evaporators, including their working principle, advantages, and disadvantages.

Table of content:

What is a forced circulation evaporator?

How does a forced circulation evaporator work?

Advantages of forced circulation evaporators

Disadvantages of forced circulation evaporators

What is a forced circulation evaporator?

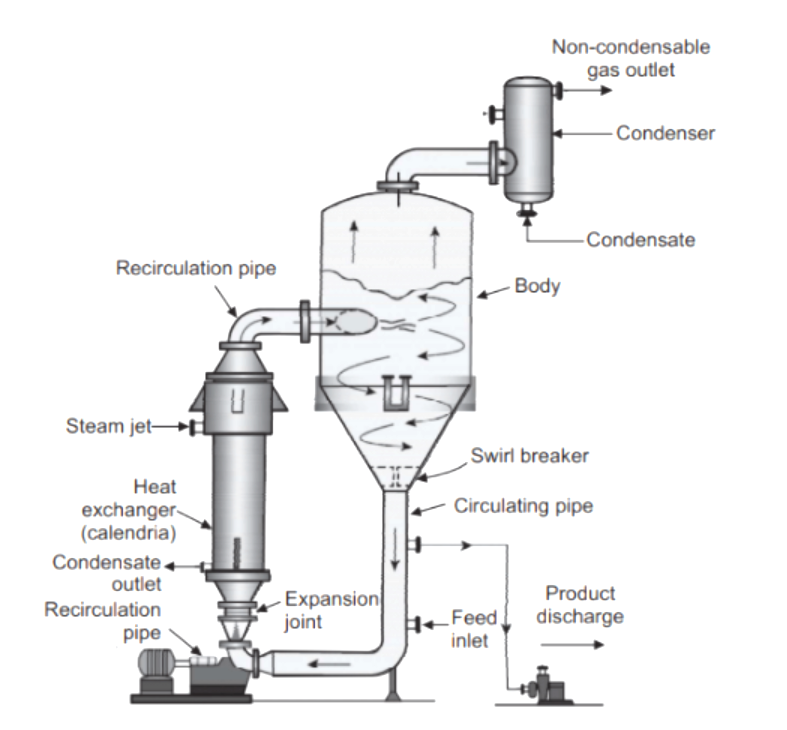

A forced circulation evaporator is a type of industrial evaporator that is used to concentrate solutions or suspensions by evaporating the solvent. Unlike natural circulation evaporators, which rely on gravity to circulate the solution, forced circulation evaporators use a pump to circulate the solution through the evaporator tubes.

Forced circulation evaporators are particularly useful for handling materials with high concentrations of solids or viscous materials that are difficult to circulate by gravity alone. They are also ideal for processing heat-sensitive materials, as the forced circulation helps to control the temperature and prevent overheating. However, they can be more expensive to operate than natural circulation evaporators due to the need for a pump and additional equipment.

A forced circulation evaporator works by circulating a solution or suspension through the tubes of an evaporator using a pump. The solution is first preheated in a heat exchanger or preheater to a temperature close to the boiling point of the solvent. The preheated solution is then pumped into the evaporator and circulated through the tubes by the pump.

The tubes are surrounded by steam or hot water, which heats the solution and causes the solvent to evaporate. As the solvent evaporates, the solution becomes more concentrated, and the remaining liquid is returned to the preheater to be reheated and recirculated through the evaporator. The concentrated solution is discharged from the evaporator, and the remaining liquid is recycled back to the preheater.

The pump is used to circulate the solution through the evaporator tubes at a high velocity, which enhances heat transfer and allows for a more efficient evaporation process. The circulation of the solution through the evaporator tubes helps to maintain a constant and precise temperature throughout the evaporator, making it suitable for processing heat-sensitive materials.

Advantages of Forced Circulation Evaporators

Forced circulation evaporators offer several advantages over other types of evaporators. Some of the main advantages are described here.

- Forced circulation evaporators use a pump to circulate the solution through the evaporator tubes, which enhances heat transfer and allows for a more efficient evaporation process.

- Forced circulation evaporators can handle solutions with high concentrations of solids or viscous materials that can be difficult to circulate by gravity alone.

- The forced circulation of the solution helps to maintain a constant and precise temperature throughout the evaporator, making it suitable for processing heat-sensitive materials.

- The constant circulation of the solution through the evaporator tubes helps to prevent fouling, which can improve the overall efficiency of the system.

Disadvantages of Forced Circulation Evaporators

Forced circulation evaporators have several disadvantages compared to other types of evaporators. These include:

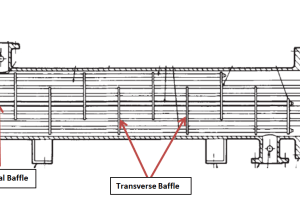

- High capital cost: Forced circulation evaporators require additional equipment, such as pumps and heat exchangers, which can make them more expensive to install and maintain compared to other types of evaporators.

- High energy consumption: The use of a pump in forced circulation evaporators requires additional energy, which can increase operational costs. The high energy consumption also contributes to higher greenhouse gas emissions.

- Increased maintenance: The use of a pump can lead to increased wear and tear on equipment, resulting in higher maintenance costs over the lifetime of the evaporator.

- Limited use for certain materials: Forced circulation evaporators may not be suitable for materials that are highly sensitive to temperature or pressure changes. This is because the circulation of the solution through the evaporator tubes can create variations in temperature and pressure that may negatively affect the material being processed.

- Greater risk of fouling: Forced circulation evaporators may be more prone to fouling due to the higher velocity of the solution through the evaporator tubes. This can lead to reduced efficiency and increased cleaning and maintenance requirements.