Diaphragm valves are a type of control valve used for controlling the flow of fluid through a pipe. It consists of a flexible diaphragm or membrane that separates the flow stream from the operating mechanism. Due to this diaphragm valves are used in applications where abrasive or corrosive fluids need to be controlled. These valves are also known for their excellent sealing capabilities.

In this post theory of diaphragm valves has been explained thoroughly along with its types, applications, advantages, and disadvantages of it.

Table of content:

1. What is a diaphragm valve?

2. How does a diaphragm valve work?

3. Types of diaphragm valve

4. Parts of diaphragm valve

5. Advantages

6. Disadvantages

7. Applications of diaphragm valves

What is a diaphragm valve?

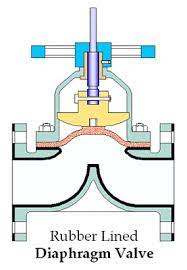

A diaphragm valve is a type of control valve that uses flexible diaphragm to control the flow of fluid. It consists of a body with an inlet and outlet port, a diaphragm and a closing mechanism. The diaphragm is typically made of flexible material such as rubber or synthetic polymer. The diaphragm is attached to movable stem.

When the valve is in the closed position, the diaphragm blocks the flow path by sealing against a seat or sealing surface within the valve body. To open or close the valve, the stem or spindle is actuated by a manual handwheel, pneumatic actuator, or electric actuator.

The flexible diaphragm plays a crucial role in sealing and controlling the fluid flow within the valve. The diaphragm also acts as a barrier between the fluid and valve internals. This prevents contamination or damage to valve internals. That's why diaphragm valves provide excellent sealing capabilities.

The flexibility of diaphragm allows it to be quickly and precisely change the stem position, which results in efficient control over the fluid flow. This inherent flexibility and resilience of the diaphragm make it well-suited for handling a variety of fluids, including corrosive or abrasive substances.

How does a diaphragm valve work?

Diaphragm valves operate by moving the flexible diaphragm to control the flow of fluid. The diaphragm is typically made of a flexible material such as rubber or a synthetic polymer, which is attached to a movable stem or spindle.

To open or close the valve, the stem or spindle is actuated by a manual handwheel, pneumatic actuator, or electric actuator, depending on the application and control requirements. The movement of the stem is directly linked to the flexing of the diaphragm.

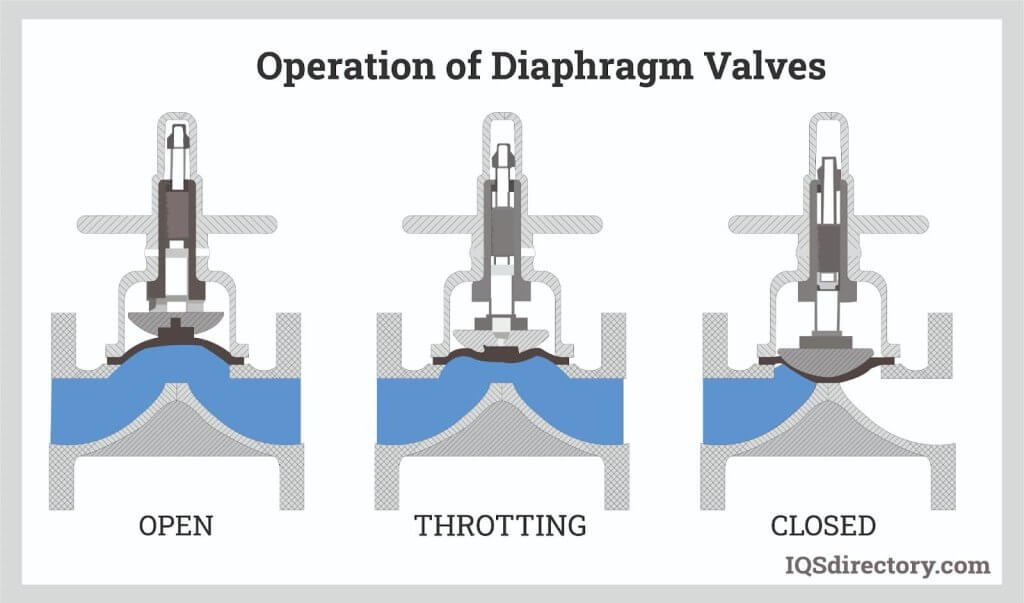

- In the closed position diaphragm will be in contact with the sealing surface of the valve body. This will block the flow of fluid through the valve. This sealing action ensures tight shut off and prevents any leakage through it. To achieve closed position of the valve, stem is turned lowered. As the stem moves downward diaphragm press against the seal and blocks the fluid flow.

- In the open position, the stem is raised. As the stem moves upward, it pulls the diaphragm away from the seat and opens the flow path. This enables the fluid to pass through the valve.

Types of diaphragm valve

There are several types of diaphragm valves available, each designed to meet specific application requirements. Details of some common types of diaphragm valves are discussed here.

Weir type diaphragm valve

In a weir type diaphragm valve, the diaphragm is shaped like a weir or a dam. It is clamped at the top and extends across the flow path, forming a weir-like shape. This weir design allows for a controlled flow through a small orifice when the valve is partially open. This design also prevents the diaphragm from being subjected to excessive strain.

Straight through diaphragm valve

A straight-through diaphragm valve has a straightforward flow path with the diaphragm positioned perpendicular to the flow direction. The distinguishing feature of a straight-through diaphragm valve is the absence of any irregularities or obstructions in the flow path. It provides excellent flow characteristics, minimal pressure drop.

Parts of diaphragm valve

A diaphragm valve consists of several key components that work together to regulate fluid flow.

Body: The body of the diaphragm valve serves as the main structure housing the internal components. It typically has an inlet port and an outlet port for fluid to enter and exit the valve.

Diaphragm: The diaphragm is a flexible membrane made of materials such as rubber or synthetic polymers. The diaphragm is strategically positioned within the valve body, separating the fluid from the valve mechanism.

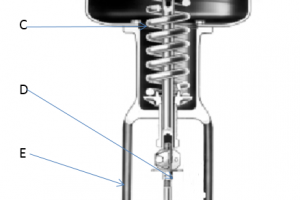

Stem: The stem, also known as the spindle, is a slender rod attached to the diaphragm. It extends through the top of the valve body and connects to the actuator. The upward and downward movement of the stem is responsible for controlling the position of the diaphragm.

Actuator: The actuator provides the necessary force to operate the diaphragm valve. It can be in the form of a manual handwheel, a pneumatic actuator, or an electric actuator.

Advantages

- Excellent sealing properties and tight shut-off capability

- Ideal for use in applications where the fluid is corrosive

- Resistant to abrasion

- Easy to clean and maintain

- Contamination Prevention and Protection of Valve Internals: Diaphragm valves do not come into contact with the fluid being controlled, which makes them ideal for use in applications where contamination is a concern.

- Diaphragm valves can be used with a wide range of fluids, including corrosive and hazardous materials.

Disadvantages

- Diaphragm valves may have limitations in terms of pressure handling capabilities. High-pressure applications may require specialized diaphragm materials or reinforced designs to ensure proper sealing and prevent diaphragm failure.

- The weir may prevent full drainage of piping.

- These valves introduce some flow restrictions due to diaphragm which results in pressure drop.

Applications of diaphragm valves

- Corrosive applications: The body and diaphragm materials can be chosen for chemical compatibility.

- Abrasive applications: The body lining can be designed to withstand abrasion and the diaphragm can be easily replaced once worn out.

- Solids-entrained liquids: The diaphragm can seal around any entrained solids and provide a positive seal.

- Slurries: The diaphragm can seal around entrained solids and provide a positive seal.