Choke valves are flow control devices mainly used in oil and gas industries during production of crude oil from an oil well. These valves typically control the flow rate of drilling fluid such as crude oil in high pressure environment. The secondary purpose of the choke valve is to create pressure drop across the valve to decrease downstream pressure in flow pipe.

These valves help manage the pressure and flow rates to prevent damage to the well or equipment and serve critical purpose during the production phase. This blog post will delve into the concept of choke valves, exploring their applications and significance in flow control.

Table of content:

1. What are choke valves?

2. Types of choke valves

2.1. Non-regulating choke valves

2.2. Regulating choke valves

3. How does a choke valve work?

4. Applications of choke valves

5. FAQs

What are choke valves?

Choke valve, sometimes also known as 'choker valve' is a type of control valve, mostly used in oil and gas production wells to control the flow of well fluids being produced. Another purpose that these valves serve is to kill the pressure from reservoir and to regulate the downstream pressure in the flowlines.

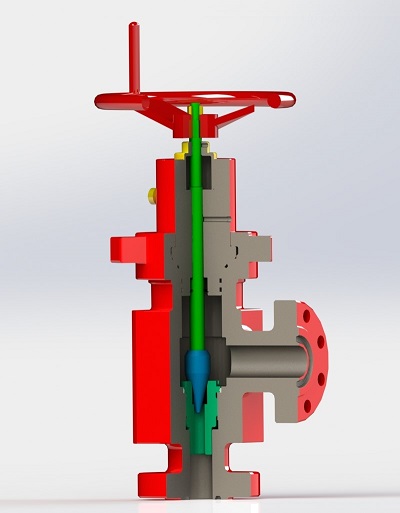

Choke valves allow fluid flow through a very small opening, designed to kill the reservoir pressure while regulating the well production. These valves feature an adjustable opening that can be manipulated to restrict or increase the flow of fluids. By reducing the size of the flow passage, choke valves create a pressure drop, which helps to regulate the flow rate.

The pressure drop across the choke valve helps maintain optimal operating conditions within the system. By manipulating the choke valve, operators can precisely control the flow rate, preventing excessive flow, and maintaining stability in the system.

The reservoir fluids can contain sand particles. Hence the choke valves are usually designed to handle an erosive service.

Types of choke valves

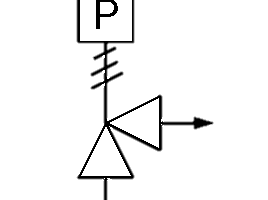

Typically oil and gas producing wells have two choke valves in series, one non-regulating valve and one regulating valve downstream to the non-regulating valve.

Non-regulating choke valves

Function of the non-regulating choke valve is to act as an on-off valve and kill the reservoir pressure to a desired operating value in the flowline. The opening in the choke valve is sized to kill the pressure when valve is fully open. The non-regulating choke valve is not used for flow regulation and hence is not sized for controlling the flow.

Over the life of an oil production well, the reservoir pressure drop as fluids are depleted from the reservoirs. Hence with dropping reservoir pressure, the non-regulating valves may have to be changed to maintain the same well production levels. Hence over the life of an oil production well, the non-regulating choke valves can be replaced with valves having increasingly larger openings for flow.

Regulating choke valves

The regulating choker valve is a flow control valve which is designed to maintain a steady production level in the flowlines and production header. Regulating choke valve is an automatic valve and valve opening can be controlled via electric or pneumatic signal from the control panel to regulate the flow in downstream flowlines.

Among other applications, choker valve can be used in liquid lines operating at very high pressures.

How does a choke valve work?

The step by step working procedure of choke valve is explained here.

- The drilling fluid such as oil or gas enters the valve through the inlet port.

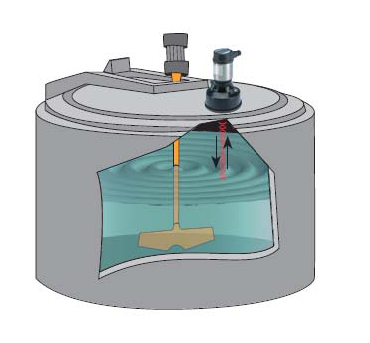

- There is an opening or orifice in the valve through which fluid passes. The size of orifice determines the available flow area for fluid to pass.

- As the fluid flows through the valve, flow area gets reduced. This reduced flow area increases fluid velocity. According to Bernoulli's principle, as the fluid's velocity increases, its pressure decreases. This pressure drop helps in regulating the flow and pressure in the downstream flowline.

- Operator can regulate the flow and pressure by adjusting valve opening or orifice. Decreasing valve opening results in higher pressure drop and lower flow rate. Increasing valve opening results in lower pressure drop and higher flow rate.

- The choke valve can be manually operated where operator adjusts valve opening or automatically operated where electronic, pneumatic or hydraulic signals are used to adjust the valve opening.

Applications of choke valves

Choke valves play an important role in the oil and gas industry, especially in well wells and production facilities. They play an important role in controlling pressure and flow during various stages of oil and gas production. A few specific applications are discussed here.

- A choke valve is installed at the top of the well to control the release of hydrocarbons from the reservoir to the surface. By varying the opening of the choke valve, operators can control the back pressure exerted on the reservoir.

- Kick and Blowout Prevention: In the event of a "kick" (abrupt influx of formation fluids) or the potential for a blowout, choke valves are used to quickly close and control the flow of fluids.

- These valves assist in preventing excessive flow rates which may lead to fluid separation, erosion or damage to the wellbore or downstream equipment.

FAQs

1. Where are choke valves commonly used?

They are prevalent in the oil and gas industry. They are used in wellhead and production applications, where they control the flow of oil, gas, and other fluids from reservoirs.

2. What is the significance of choke valves in the oil and gas industry?

They are crucial in the oil and gas industry because they help manage well production and control flow rates, enabling efficient reservoir management, preventing blowouts, and optimizing production operations.

3. Are there safety considerations when working with choke valves?

Yes, working with choke valves in high-pressure and high-temperature environments requires adherence to safety protocols and standards. Operators must be trained to handle these valves safely to prevent accidents and maintain equipment integrity.

4. Can choke valves be used in other industries besides oil and gas?

While choke valves are most commonly associated with the oil and gas industry, they can also be used in applications where precise flow control and pressure regulation are required, such as in chemical processing, power generation, and petrochemical industries.

5. How do I select the right choke valve for my application?

The choice of a choke valve depends on factors like fluid properties, pressure, temperature, and required flow rates. Consulting with a qualified engineer or valve specialist is essential to select the appropriate choke valve for your specific application.

6. Can choke valves be customized for specific requirements?

Yes, choke valves can be customized to meet specific application requirements. Manufacturers often provide options for materials, choke bean sizes, and actuator types to tailor the valve to your needs.