Pressure relief valves (PRVs) or safety valves play a critical role in safeguarding equipment and systems from overpressure incidents. These valves are designed to open and release excess pressure when it exceeds a predetermined set point. However, to ensure their reliability and effectiveness, it is essential to conduct thorough testing, including the evaluation of the Cold Differential Test Pressure (CDTP).

CDTP is a crucial aspect of PRV testing and refers to the pressure difference between the valve's inlet and outlet when it is subjected to a cold condition. In other words, CDTP measures the valve's ability to open and relieve pressure when there is no process flow or fluid passing through it.

Table of content:

1. What is back pressure?

1.1. Superimposed back pressure

1.2. Built-up back pressure

2. Cold differential test pressure

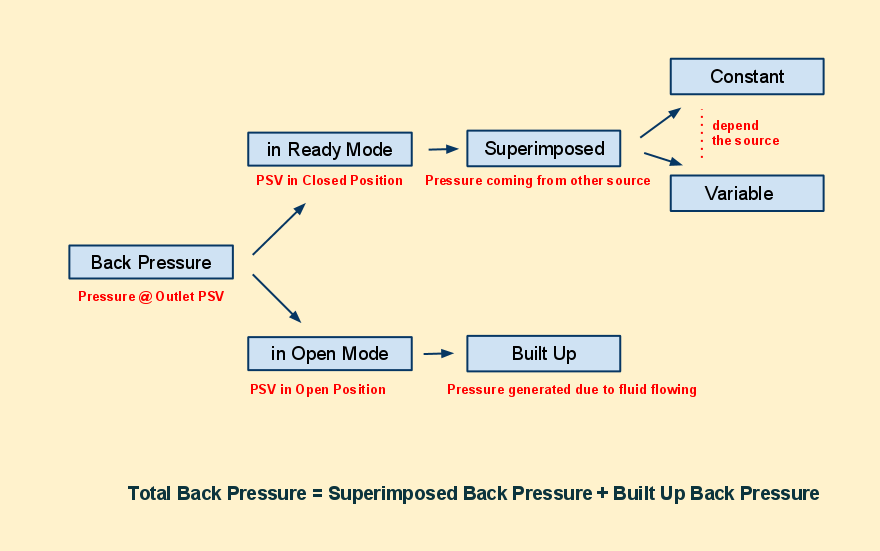

What is back pressure?

To understand the concept of Cold Differential Test Pressure (CDTP), it is important to first understand the role of back pressure in case of opening of conventional, balance bellows and pilot type relief valves.

Back pressure is the pressure that is exerted on the outlet of a pressure relief valve (PRV) by the fluid that is flowing out of the valve. Back pressure can be caused by a number of factors, including:

- The resistance of the piping system that the PRV is connected to

- The presence of other valves or devices in the system

- The natural resistance of the fluid itself

Back pressure can have a significant impact on the performance of a PRV. In particular, it can reduce the amount of fluid that the valve can discharge and it can also increase the opening pressure of the valve.

Superimposed back pressure

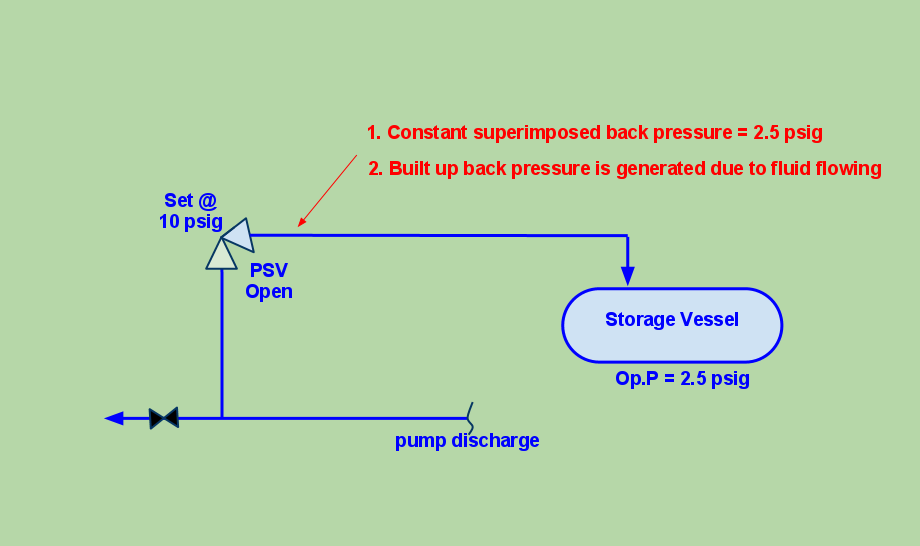

Superimposed back pressure is the static backpressure that exists on the outlet of the pressure relief valve, when the valve is closed. This pressure can be constant or variable depending on conditions downstream to the relief valve, before the relief valve can discharge.

Built-up back pressure

Built-up back pressure is the backpressure generated due to pressure losses at the outlet of an open relief valve when it is discharging. This pressure depends on the pressure of the vent header downstream to the relief valve and the relieving flowrate which is being discharged. The built-up backpressure is the pressure in the vent header plus pressure drop in the line from relief valve to vent header, when the valve is discharging at full capacity.

When the relief valve is discharging, effects of superimposed and built-up back pressure exist together and felt as the combined back pressure.

Both superimposed back pressure and built-up back pressure can reduce the amount of fluid that the PRV can discharge and they can also increase the opening pressure of the valve. The amount of reduction in discharge capacity and increase in opening pressure will depend on the magnitude of the back pressure.

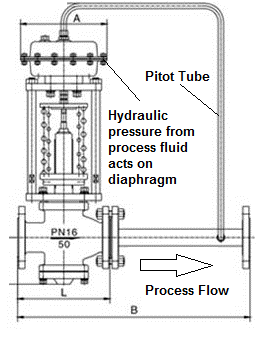

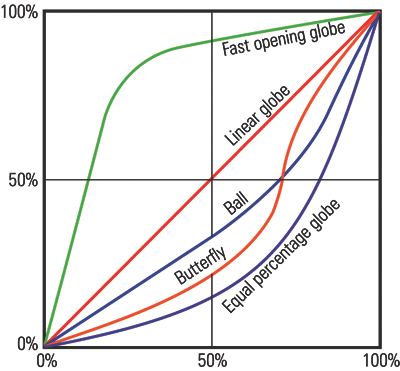

For certain relief valve designs, the backpressure on the valve acts as a closing force and can affect the opening pressure for the valve. ‘Conventional’ valves are highly susceptible to this effect and hence not used in applications where high backpressure is expected. ‘Balanced Bellows’ and ‘Pilot Operated’ relief valves relatively shielded from effects of high backpressure.

Cold Differential Test Pressure (CDTP)

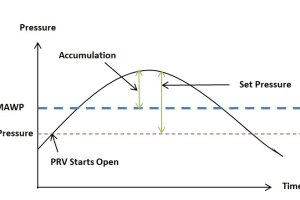

A relief valve is a safety device that is used to prevent a system from overpressurizing. When the pressure in a system exceeds the set pressure of the relief valve, the valve opens and releases the excess pressure.

Conventional relief valves are affected by backpressure. If the backpressure is higher than atmospheric pressure, the valve must be designed to open at a lower differential pressure. The differential pressure is the difference between the pressure on the inlet side of the valve and the pressure on the outlet side of the valve.

However, when the valve is tested before installation, it only sees atmospheric pressure as backpressure. To open the valve at the same differential pressure, the set point pressure must be lower than the original design set point pressure. This set point value is known as cold differential test pressure (CDTP).

For pilot operated and balanced bellows type relief valves, effect of backpressure on valve opening characteristics is very low and hence CDTP is the same as the original design set point pressure value.