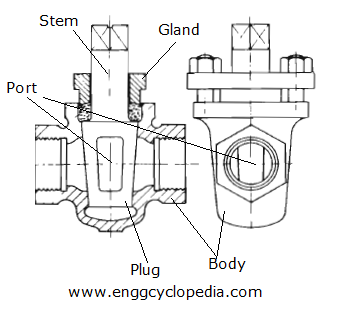

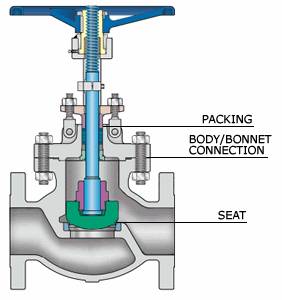

Plug valves are also known as 'cock valves'. A plug valve is one the simplest and earliest valve design. A plug valve consists of a plug which is generally tapered toward the bottom, but sometimes can be parallel. This plug fits in a seating in the body of the valve as indicated in the schematic. The plug also contains a port to allow the fluid flow as indicated in the figure. This port can be rectangular or round in shape. The rotation of the plug and hence the port, can be used to control the opening to allow the fluid flow. Rotating the plug by 900 can completely open or close the valve. Plug valve are not usually used for regulating the flow, but sometimes specially designed plug can be used for flow regulation.

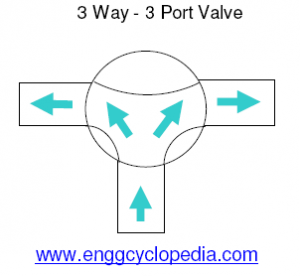

Multiport Valves

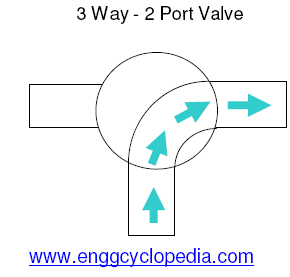

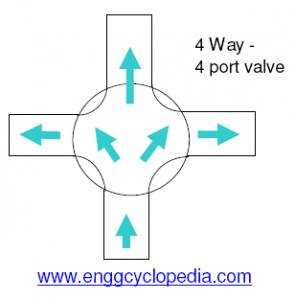

Plug valves can also be used in the form of multiport valves as indicated in the figures below.

|

3 Way - 2 Port valve |

|

|

3 Way - 3 Port Valve |

|

4 Way - 4 Port valve |

Advantages

Plug valves have very simple design and fewer parts. Plug valves are easy to clean and can be cleaned without having to remove the body from piping system. Plug valves provide reliable leaktight service. They can be quickly opened or closed and they offer low resistance to the flow.

Disadvantages

Due to large amount of friction to rotate the plug, greater force is required to operate the these valves. For larger valves actuators may be needed. Usually plug valves cost more than ball valves, which have similar design.

Applications of plug valves

- On-off control on flow

- Moderate flow throttling

- Flow diversion using multiport valves